Sealing slurry for low-temperature environment as well as preparation method and application thereof

A low-temperature environment, slurry technology, used in building insulation materials, building components, buildings, etc., to achieve the effect of good bonding performance

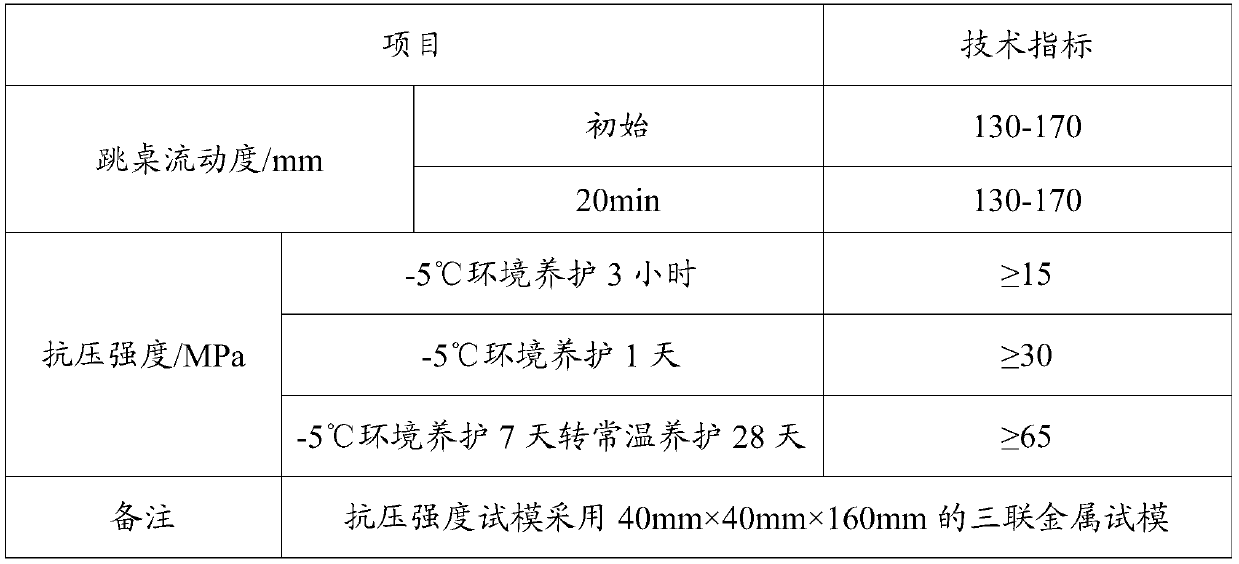

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The low-temperature environment sealant of this embodiment consists of the following components by weight:

[0032] (1) Rapid hardening sulfoaluminate cement R·SAC52.5: 45 parts

[0033] (2) Silica fume: 5 parts

[0034] (3) Quartz sand: 50 parts

[0035] (4) Azodimethylamide: 0.02 parts

[0036] (5) Silicone defoamer P803: 0.1 parts

[0037] (6) Nitrite rust inhibitor: 0.5 parts

[0038] (7) Polyacrylamide: 0.1 parts

[0039] (8) Triterpene saponin air-entraining agent: 0.01 parts

[0040] (9) Boric acid retarder: 0.2 parts

[0041] (10) Calcium formate: 0.04 parts

[0042] Mix the above components with a gravity-free high-efficiency mixer for 10 minutes and then package them in double-layer packaging bags to obtain the sealing paste for low-temperature environments. During on-site construction, the sealing slurry and water are added into the mixer according to the ratio of water-cement weight ratio of 0.14, without heating (10°C is enough), and the mixture is ...

Embodiment 2

[0045] The low-temperature environment sealant of this embodiment consists of the following components by weight:

[0046] (1) Rapid hardening sulfoaluminate cement R·SAC42.5: 45 parts

[0047] (2) fly ash: 10 parts

[0048] (3) Quartz sand: 45 parts

[0049] (4) Compound of naphthalene-based water-reducer and melamine-based water-reducer at a weight ratio of 1:1: 0.10 parts

[0050] (5) Azodimethylamide: 0.02 parts

[0051] (6) Silicone defoamer DF6352: 0.1 parts

[0052] (7) Amino carboxylic acid rust inhibitor: 0.5 parts

[0053] (8) Methyl cellulose ether: 0.1 parts

[0054] (9) Triterpene saponin air-entraining agent: 0.01 part

[0055] (10) Tartaric acid retarder: 0.2 parts

[0056] (11) Lithium carbonate: 0.03 parts

[0057]Mix the above components with a gravity-free high-efficiency mixer for 10 minutes and then package them in double-layer packaging bags to obtain the sealing paste for low-temperature environments. During on-site construction, the sealing slu...

Embodiment 3

[0060] The low-temperature environment sealant of this embodiment consists of the following components by weight:

[0061] (1) High Belite sulfoaluminate cement 42.5: 40 parts

[0062] (2) Slag fine powder: 10 parts

[0063] (3) Washed river sand: 50 parts

[0064] (4) Azodimethylamide: 0.04 parts

[0065] (5) Silicone defoamer B-328F: 0.1 parts

[0066] (6) Amino alcohol rust inhibitor: 0.4 parts

[0067] (7) Polyethylene glycol: 0.1 part

[0068] (8) Triterpene saponin air-entraining agent: 0.01 parts

[0069] (9) Gluconate retarder: 0.26 parts

[0070] (10) Calcium nitrite: 0.03 parts

[0071] Mix the above components with a gravity-free high-efficiency mixer for 10 minutes and then package them in double-layer packaging bags to obtain the sealing paste for low-temperature environments. During on-site construction, the sealing slurry and water are added into the mixer according to the ratio of water-cement weight ratio of 0.14, without heating (10°C is enough), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com