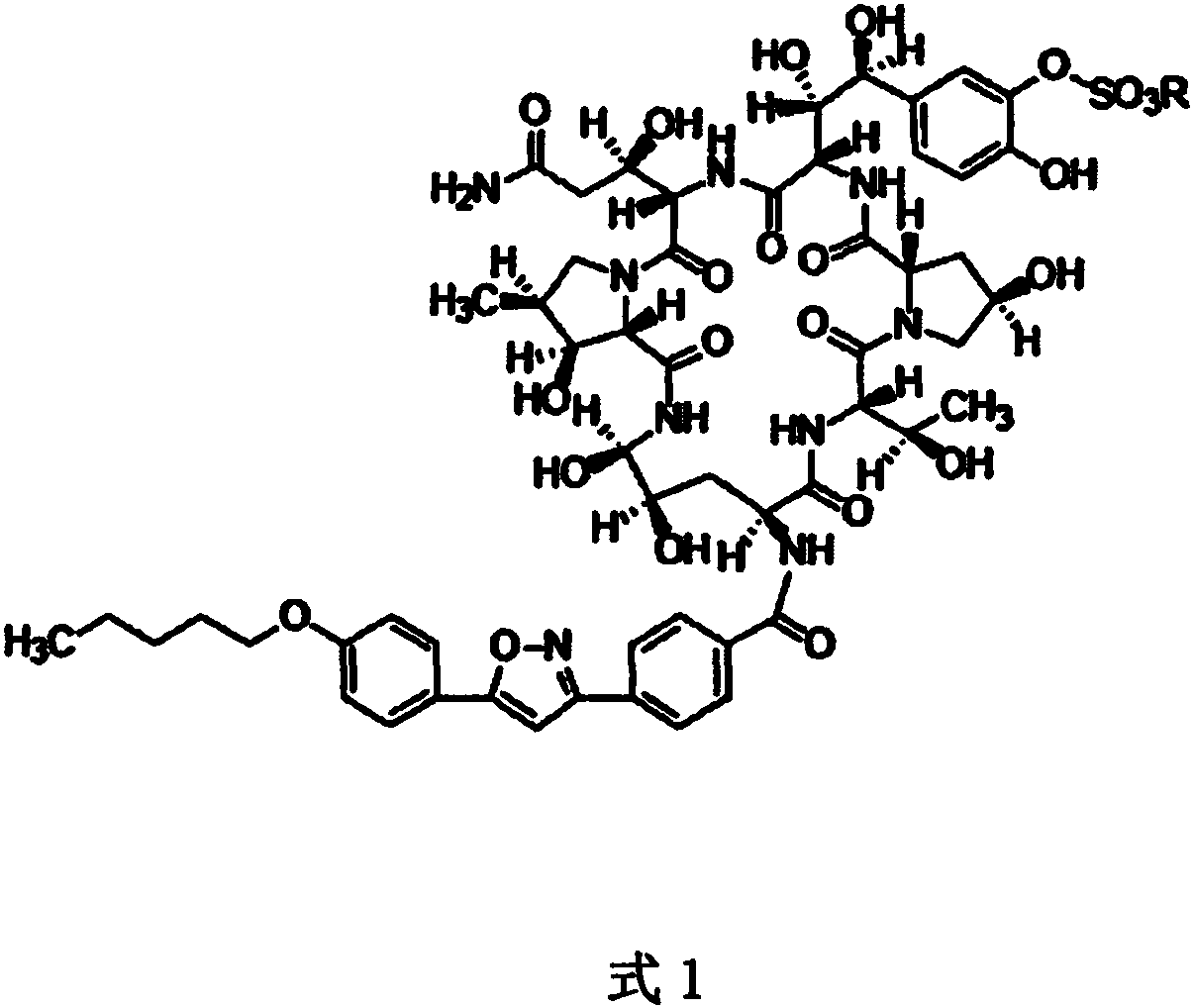

High-purity micafungin or salt thereof, and preparation method and application thereof

A micafungin and high-purity technology, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, and cyclic peptide components, can solve the problems of poor product stability, increase the difficulty of industrial production, and high equipment investment, so as to reduce the process Operational difficulty coefficient, good product stability, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of micafungin with low solvent residue and low salt

[0069] Dissolve the compound of formula 1 (2.0g) in the system of methanol (0.13ml) and water (2.2ml) at 15°C, add isobutanol (25ml) after dissolving, stir well, and slowly drop Ethyl acetate (27.4ml), after dropping, stirred at 12°C for 12h. It was filtered, washed several times with a mixture of methanol and ethyl acetate (1.7:1), and the solid was collected by centrifugation. Introduce air with a humidity above 85%, then place the sample in a vacuum drying oven, and place a plate of tap water at the bottom of the vacuum drying oven, dry it at 15°C for 2 hours under vacuum conditions, and then wait until the humidity of the drying oven is 75%. Continue vacuum drying at 15° C. for 14 h to obtain micafungin sodium (1.50 g, mass yield 75%). HPLC showed that the purity was 99.90%, the single impurity was below 0.1%, and the mass percentages of isobutanol, methanol, ethyl acetate and ethanol were 0.03%, 0....

Embodiment 2

[0071] Preparation of micafungin with low solvent residue and low salt

[0072] Dissolve the compound of formula 1 (2.0g) in the system of methanol (0.13ml) and water (2.2ml) at 10°C, add isobutanol (25ml) after dissolving, stir well, and slowly drop Ethyl acetate (27.4ml), after dropping, stirred at 8°C for 2h. It was filtered, washed several times with a mixture of methanol and ethyl acetate (1.7:1), and the solid was collected by centrifugation. Introduce air with a humidity above 82%, then place the sample in a vacuum drying oven, and place a plate of tap water at the bottom of the vacuum drying oven, dry it at 10°C for 4 hours under vacuum conditions, and then wait until the humidity of the drying oven is 78%. Continue vacuum drying at 10° C. for 10 h to obtain micafungin sodium (1.50 g, mass yield 75%). HPLC showed that the purity was 99.90%, the single impurity was below 0.1%, and the mass percentages of isobutanol, methanol, ethyl acetate and ethanol were 0.02%, 0.05...

Embodiment 3

[0074] Preparation of micafungin with low solvent residue and low salt

[0075] Under the condition of 15°C, dissolve the raw material (2.0g) containing the compound of formula 1 in the system of methanol (0.25ml) and water (2.2ml), add isobutanol (25ml) after dissolving, and stir evenly. Ethyl acetate (30ml) was slowly added dropwise, and the mixture was stirred at 15°C for 2h. It was filtered, washed several times with a mixture of methanol and ethyl acetate (1.7:1), and the solid was collected by centrifugation. Introduce air with a humidity above 88%, then place the sample in a vacuum drying oven, and place a plate of pure water at the bottom of the vacuum drying oven, dry at 15°C for 6 hours under vacuum conditions, and then wait until the humidity of the drying oven is 80% , and continued vacuum drying at 15° C. for 12 h to obtain micafungin sodium (1.70 g, mass yield 85%). HPLC showed a purity of 99.91%. The mass percent contents of isobutanol, methanol, ethyl acetat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com