High-strength dispersing slurry dye mixture and application thereof

A dye mixture and disperse dye technology, which is applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of reducing the sales range of dyes, consuming energy to dry waste gas, and increasing transportation costs, etc., to achieve shortened production process and high strength. , The effect of reducing the production of industrial waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Step 1, at room temperature, weigh 15.7 grams of disperse blue dye 291:4, 1.8 grams of disperse blue dye 79:1, 6.6 grams of disperse violet dye N-2R, 15.9 grams of disperse orange dye 288, 3.2 grams of glycerin, 2.0 grams of disperse Agent NNO, 1.5 grams of methyl stearate polyoxyethylene ether sulfonate, 0.5 grams of sodium secondary alkyl sulfonate, 2.5 grams of oleyl alcohol polyoxyethylene ether, 2.5 grams of glycerin polyoxyethylene ether, 0.5 grams of glycerin polyoxyethylene Ether oleic acid ester, add 53.5 g of water and quickly beat evenly.

[0062] In step 2, the slurry is put into a sand mill for circular grinding for 3-4 hours until the fineness is 300nm-500nm.

[0063] Step 3, after filtering, high-strength slurry-like disperse dyes are obtained.

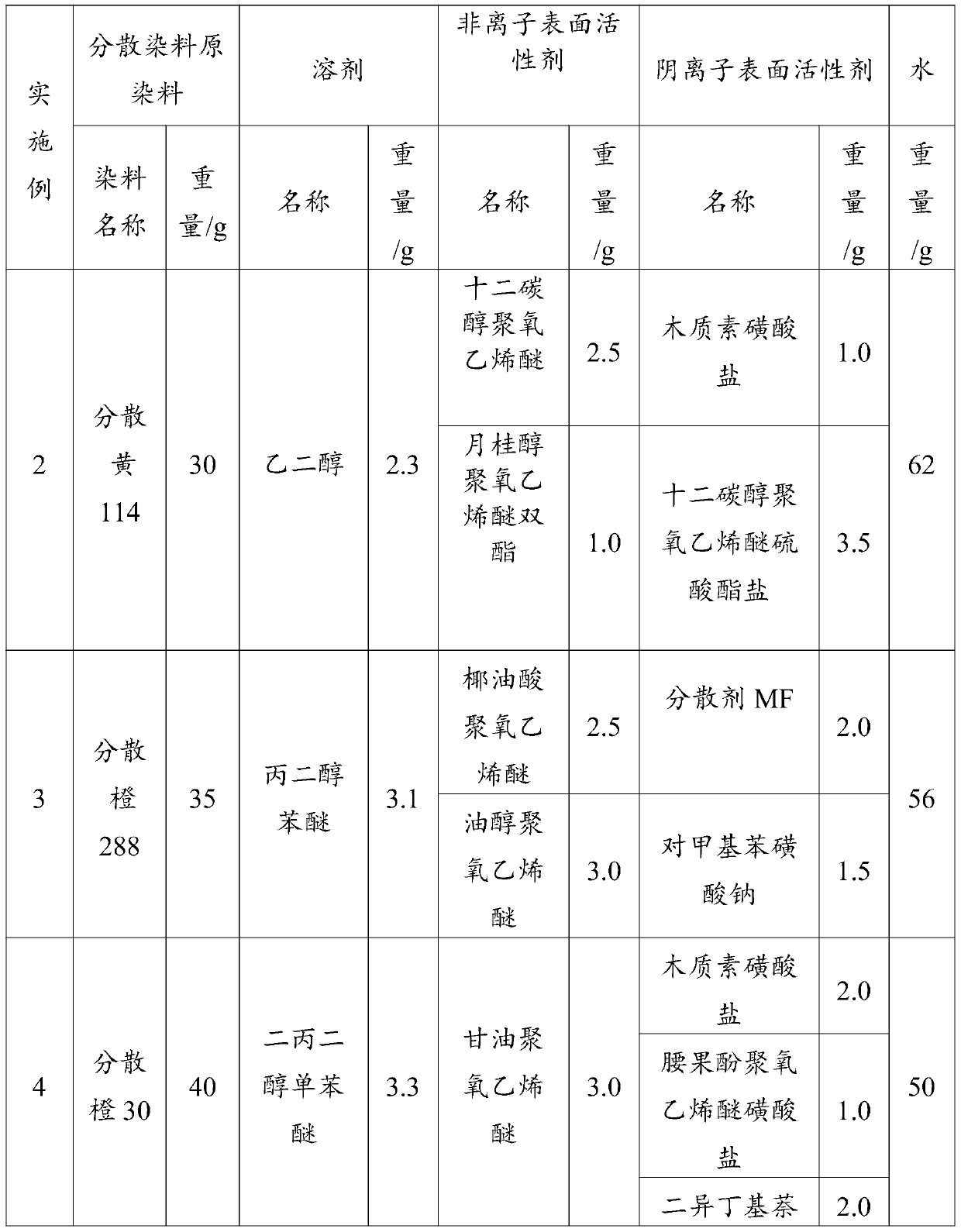

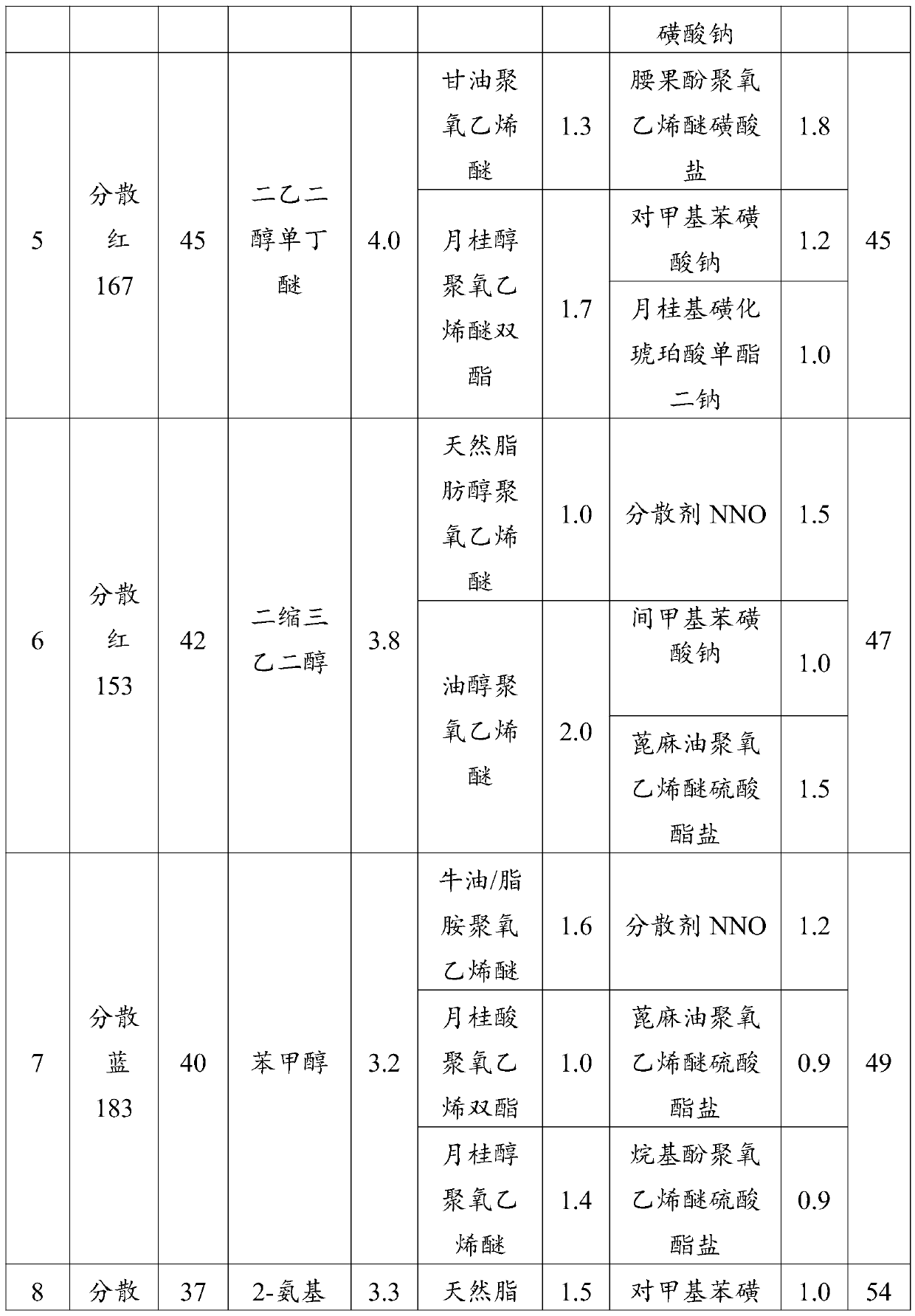

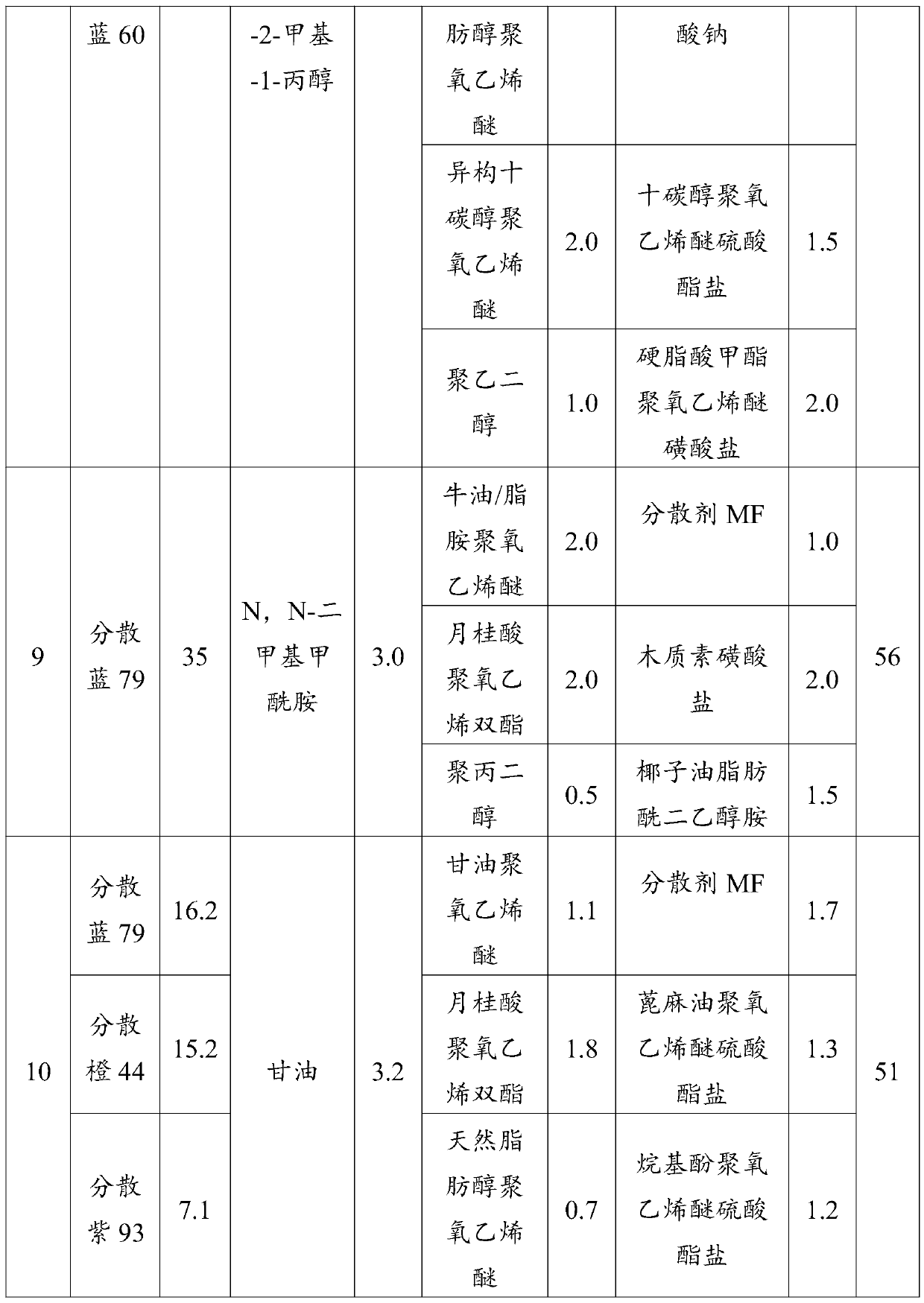

[0064] Repeat the method of Example 1, adopt different dye proportions, select different auxiliary agents and solvents, and make different high-strength dispersed paste dye mixtures. The formulas of each embodim...

experiment example 1

[0073] Embodiment 1 and commercially available granular disperse dyes were subjected to performance tests. The specific test method is as follows: Weigh 0.5 g of the granular disperse dyes of Example 1 and Comparative Example and place them in 500 mL of water respectively to prepare a disperse dye suspension. Take 50mL of disperse dye suspension and mix it with 50mL of water, adjust the pH of the dyeing bath to 5 with acetic acid, then raise the temperature to 60°C, and at the same time put 5g of polyester fiber into it for high temperature and high pressure dyeing, heat up to 130°C within 35 minutes, keep warm After 45 minutes, cool to 80°C and sample.

[0074] Observe the shade of the cloth sample and measure its dye strength and apparent depth using the method specified in GB / T6688-2008, and measure the COD of the dyeing residual liquid with Lianhua Technology 5B-3V V8 Rapid Chemical Oxygen Demand Tester. The measured data is shown in Table 2.

[0075] Table 2

[0076] ...

experiment example 2

[0079] Performance tests were performed on Examples 2-11 and the corresponding commercially available granular disperse dyes. The specific test method is as follows: Weigh 0.5 g of the granular disperse dyes of the examples and the corresponding comparative examples and place them in 500 mL of water respectively to prepare a disperse dye suspension. Take 50mL of disperse dye suspension and mix it with 50mL of water, adjust the pH of the dyeing bath to 5 with acetic acid, then raise the temperature to 60°C, and at the same time put 5g of polyester fiber into it for high temperature and high pressure dyeing, heat up to 130°C within 35 minutes, keep warm After 45 minutes, cool to 80°C and sample.

[0080] Lianhua Technology 5B-3V V8 Rapid Chemical Oxygen Demand Tester was used to measure the COD of the dyeing residue, and the measured data are shown in Table 3.

[0081] table 3

[0082]

[0083]

[0084] Comparing the high-strength disperse paste dye mixture prepared in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com