Treatment method of metal tailings

A metal tailings and treatment method technology, applied in the field of solid waste recycling, can solve the problems of high heavy metal content, complex element composition, and aggravate the difficulty of recycling useful elements, and achieve the effect of maintaining the stability of the ecological environment and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

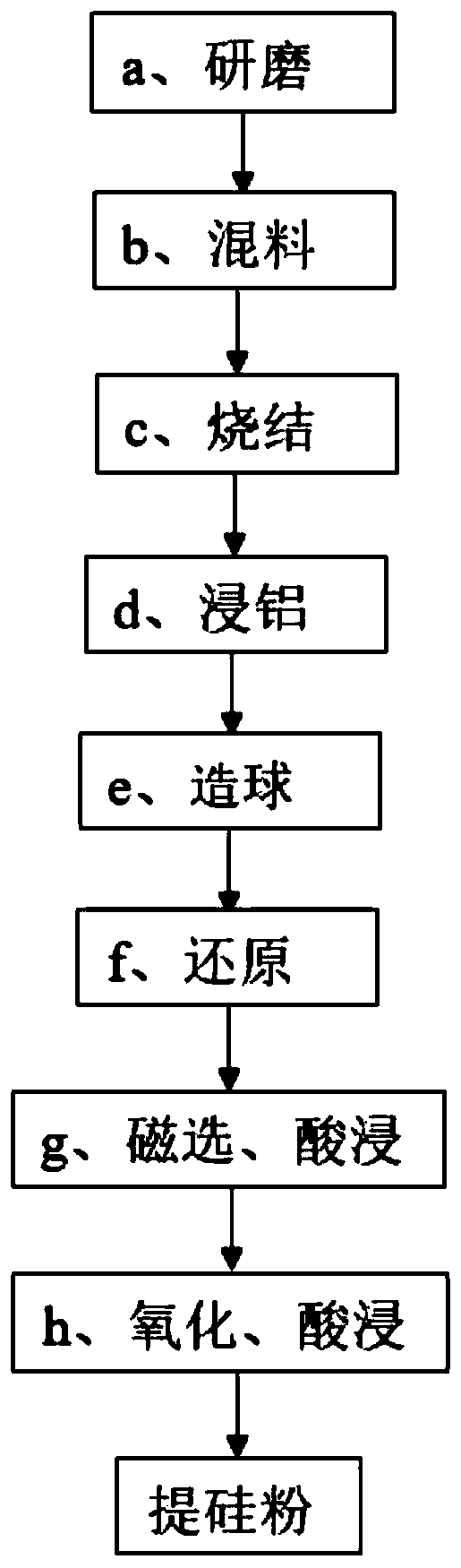

Image

Examples

Embodiment 1

[0054] This embodiment deals with Xilin lead-zinc tailings, which contains elements such as zinc, lead, copper, cadmium, iron, silicon (muscovite, quartz), aluminum (gross garnet). The process is as follows:

[0055] Step a: Grinding the lead-zinc tailings to 200 mesh lead-zinc tailings powder.

[0056] Step b: Add water, NaOH, and quicklime to the lead-zinc tailings powder to make a slurry, so that the molar amount of sodium hydroxide in the slurry: the sum of the molar amounts of alumina+iron oxide+silica is equal to 2:1.1; the molar amount of calcium oxide is equal to 2:1.1; Quantity: The molar quantity of silicon oxide is equal to 1:1.1.

[0057] Step c: drying the slurry outside the kiln, and sintering the dried raw materials at 1150° C. for 4 hours to obtain sintered clinker.

[0058] Step d: Using a sodium carbonate solution with a concentration of 20 g / L, leaching under constant stirring at room temperature for 5 hours to obtain an aluminum-containing solution, that ...

Embodiment 2

[0066] This embodiment deals with Dexing copper tailings, which contain Zn, Pb, Al, Si, Fe and other elements. The process is as follows:

[0067] Step a: Grinding the copper tailings to 200 mesh copper tailings powder.

[0068] Step b: Add water, NaOH, and quicklime to the copper tailings powder to make a slurry, so that the molar amount of sodium hydroxide in the slurry: the sum of the molar amounts of alumina+iron oxide+silica equals 2:1; the molar amount of calcium oxide : The molar weight of silicon oxide is equal to 1:1.

[0069] Step c: drying outside the kiln, and sintering the dried raw materials at 1150° C. for 4 hours to obtain sintered clinker.

[0070] Step d: Using a sodium carbonate solution with a concentration of 25 g / L, leaching under constant stirring at room temperature for 5 hours to obtain a sodium metaaluminate solution, and separating the solid and liquid to obtain a solid slag.

[0071] Step e: drying the solid slag and crushing it into 200-mesh min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com