Preparation method of metal nitride hard mask

A nitride and hard mask technology, which is applied in the field of metal nitride hard mask preparation, can solve the problems of high resistivity, distortion, high-voltage stress of TiN hard mask resistivity, etc., and achieve the effect of improving film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

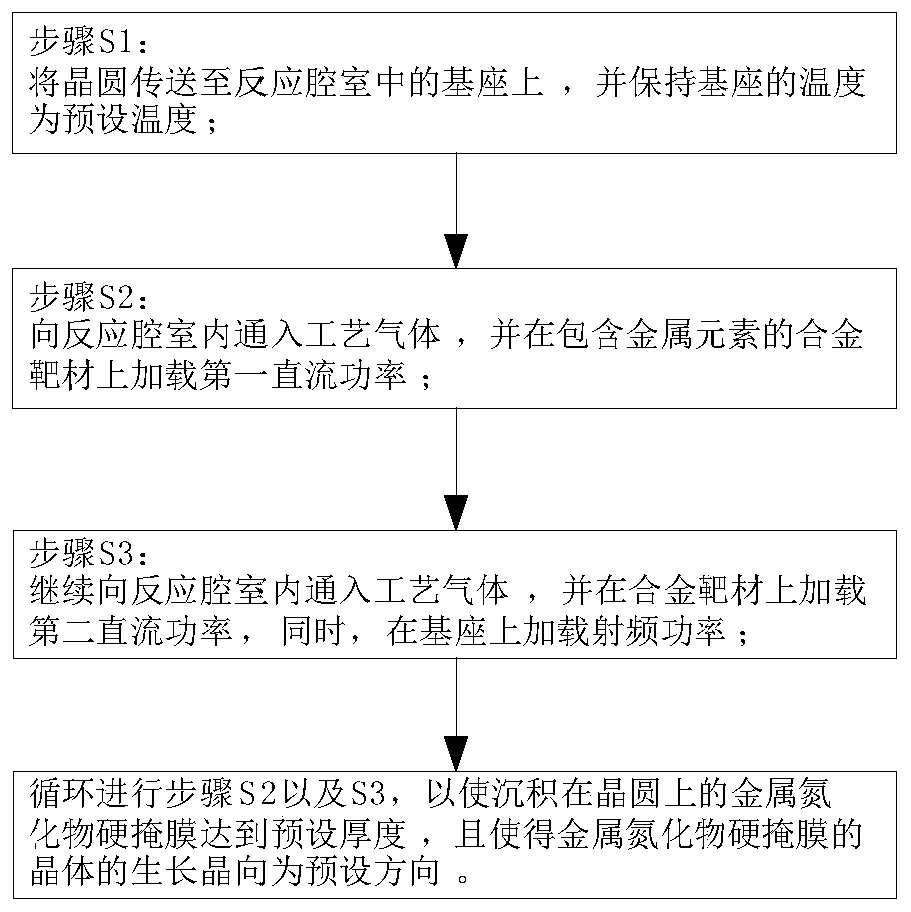

[0024] Such as figure 1 As shown, the preparation method of the metal nitride hard mask provided by the present invention comprises the following steps:

[0025] Step S1: transferring the wafer to the base in the reaction chamber, and keeping the temperature of the base at a preset temperature;

[0026] Step S2: introducing process gas into the reaction chamber, and applying the first DC power to the alloy target containing metal elements;

[0027] Step S3: Continue to feed process gas into the reaction chamber, and apply a second DC power to the alloy target, and at the same time, apply radio frequency power to the base;

[0028] Steps S2 and S3 are performed cyclically, so that the metal nitride hard mask deposited on the wafer reaches a predetermined thickness, and the crystal growth direction of the metal nitride hard mask is a predetermined direction.

[0029] Wherein, the main purpose of step S2 is to deposit a buffer layer on the wafer. Preferably, the first direct c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com