Preparation method of hybrid cross-linked transparent ionic conductive organic hydrogel fibers

A hydrogel fiber, hybrid cross-linking technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of easy evaporation, difficult continuous manufacturing of hydrogel fiber, freezing moisture, etc., to improve the resistance Effects of low temperature performance, improved anti-evaporation performance, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

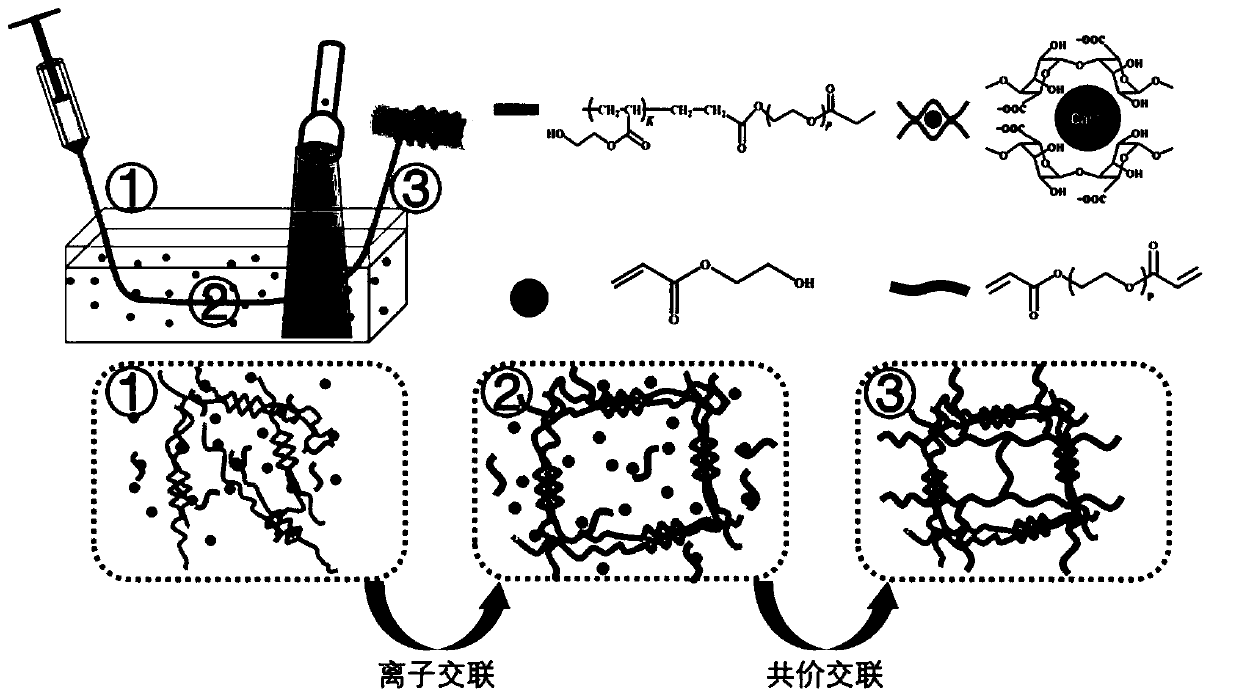

[0043] 1. Preparation of hybrid cross-linked transparent ion-conducting organic hydrogel fibers

[0044] (1) 0.2g of sodium alginate powder was dissolved in 8mL of deionized water, and magnetically stirred overnight to fully dissolve. Then add 2g of polyethylene glycol diacrylate (PEGDA) powder, 150mg of photoinitiator I2959 (2-hydroxyl-4'-(2-hydroxyethoxy)-2-methylpropiophenone), avoid light and dissolve with magnetic stirring After completion, 1 g of hydroxyethyl acrylate (HEA) was added, and magnetically stirred in the dark for 30 minutes to obtain a light yellow transparent homogeneous PEGDA hydrogel spinning stock solution for use.

[0045] (2) The spinning stock solution is packed into a 10ml syringe, and spun into a coagulation bath (0.05MCaCl) through a stainless steel needle (19G). 2aqueous solution). Ultraviolet light (UPP0404A, Uvata (Shanghai) Precision Optpelectronics Co., Ltd. = 365 nm) was applied above the coagulation bath to initiate cross-linking polymeriza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com