Nylon 56 and cellulose fiber blended fabric alkaline co-bath dip dyeing method

A cellulose fiber and dyeing method technology, which is applied in the field of alkaline same-bath dip dyeing and dyeing of nylon 56 and cellulose fiber blended fabrics, can solve the problems of difficult dyeing of blended fabrics, inconsistent fiber color and light, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

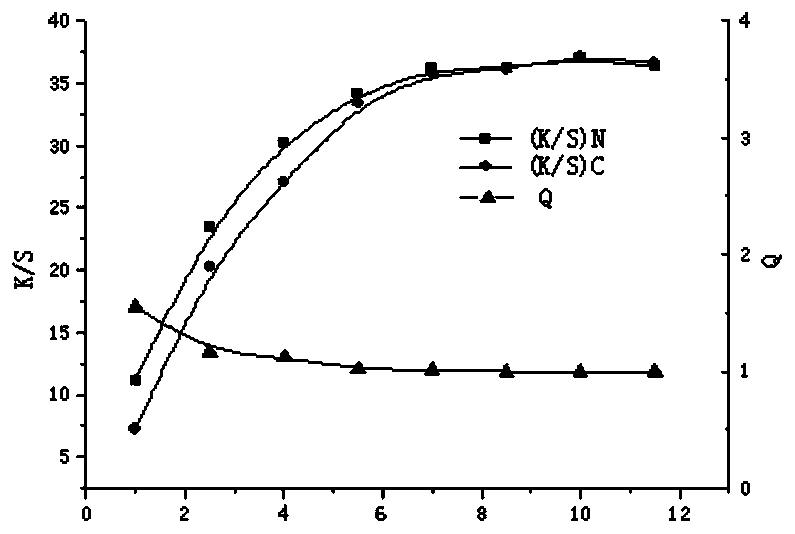

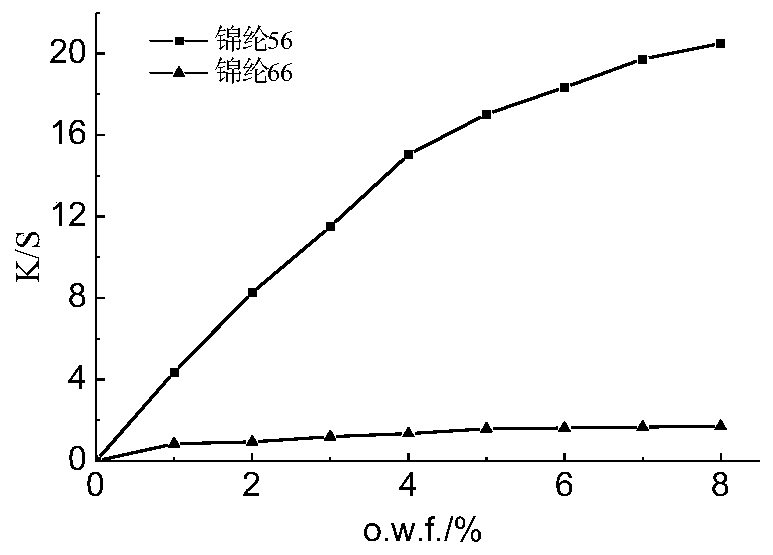

[0094] Specific Example 1: Homochromic test of nylon / cotton (60 / 40) blended fabrics dyed with different vat dyes

[0095] In this embodiment, there are two kinds of blended fabrics: one is the nylon 56 / cotton blended fabric in the present invention, and the other is the commercially available nylon 66 and cotton blended fabric, and a comparative test is done.

[0096] Full bath reduction: the bath ratio is 1:5, take 2.5% (o.w.f) dye vat dye, 2g / L caustic soda, 3g / L hydrosulfite, and water at 50°C, reduce for 10min to prepare a reducing solution, which is prepared and used now;

[0097] Dip-dyeing dyeing process: add 1% (o.w.f) leveling agent MCH-312 and 2g / L yuan Mingfen, add 2g of the object to be dyed, heat up to 60°C at 2°C / min, keep the temperature for 40min, cool down and take out the sample, at 50°C Oxidize in 4g / L hydrogen peroxide for 15min, take out the sample and wash it with hot water at 50℃, soaping (soap flakes 3g / L, anhydrous sodium carbonate 3g / L, 50℃, 10min, ba...

Embodiment 2

[0101] Embodiment 2: Vat dye dry cylinder method reduction and exhaust dyeing nylon 56 / cotton (60 / 40) blended fabric

[0102] Dye drying cylinder reduction method: According to the bath ratio of 1:5, take Vat Red 6B dye dosage 6% (o.w.f), first add 2 / 3 of the total amount of caustic soda (5g / L), hydrosulfite (5g / L), 1 / 3 water, at 55°C, reduce for 10 minutes to prepare a reducing solution, which is prepared and used immediately;

[0103] Exhaust dyeing process: add 1.5% (o.w.f) leveling agent MCH-312 and 5g / L Yuanming powder, add the remaining 1 / 3 caustic soda, 1 / 3 hydrosulfite, 2 / 3 water, add 2g of the dyed material, and heat at 2°C / min to raise the temperature to 65°C, keep it warm for 40min, cool down and take out the sample, oxidize it in 4g / L hydrogen peroxide at 50°C for 15min, take out the sample and wash it with hot water at 60°C, soaping (soap flakes 3g / L, anhydrous sodium carbonate 3g / L L, 50°C, 10min, bath ratio 1:10), rinse with water at room temperature, and dry...

Embodiment 3

[0106] Embodiment 3: Vat dye full bath method reduction dyeing nylon 56 / cotton (60 / 40) blended fabric

[0107] Dye full-bath method reduction: according to the bath ratio of 1:5, take 3% (o.w.f) dye reduction RSN, the specified amount of 2g / L caustic soda, 3g / L hydrosulfite, and water at 55°C for 10 minutes to prepare a reduction solution. Ready to use;

[0108] Exhaust dyeing process: add 1.5% (o.w.f) leveling agent MCH-312 and 3g / L Yuanming powder, add 2g of the dyed material, heat up to 65°C at 2°C / min, keep it warm for 40min, take out the sample after cooling down, and set the temperature at 50°C Oxidation treatment in 4g / L hydrogen peroxide for 15min, take out the sample, rinse with hot water at 60°C, soap wash (soap flakes 3g / L, anhydrous sodium carbonate 3g / L, 50°C, 10min, bath ratio 1:10), rinse with normal temperature water, Let dry to finish staining.

[0109] The experimental results are shown in Table 3.

[0110] Referring to the above process flow, using differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com