Algan-based deep ultraviolet LED epitaxial structure and preparation method of mg-doped quantum well

An epitaxial structure and quantum well technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the difficulties in growing materials on semi-polar and non-polar surfaces, limit luminous efficiency, and light extraction Low efficiency and other issues, to achieve the effect of improving light extraction efficiency, improving radiation recombination efficiency, and enhancing radiation recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

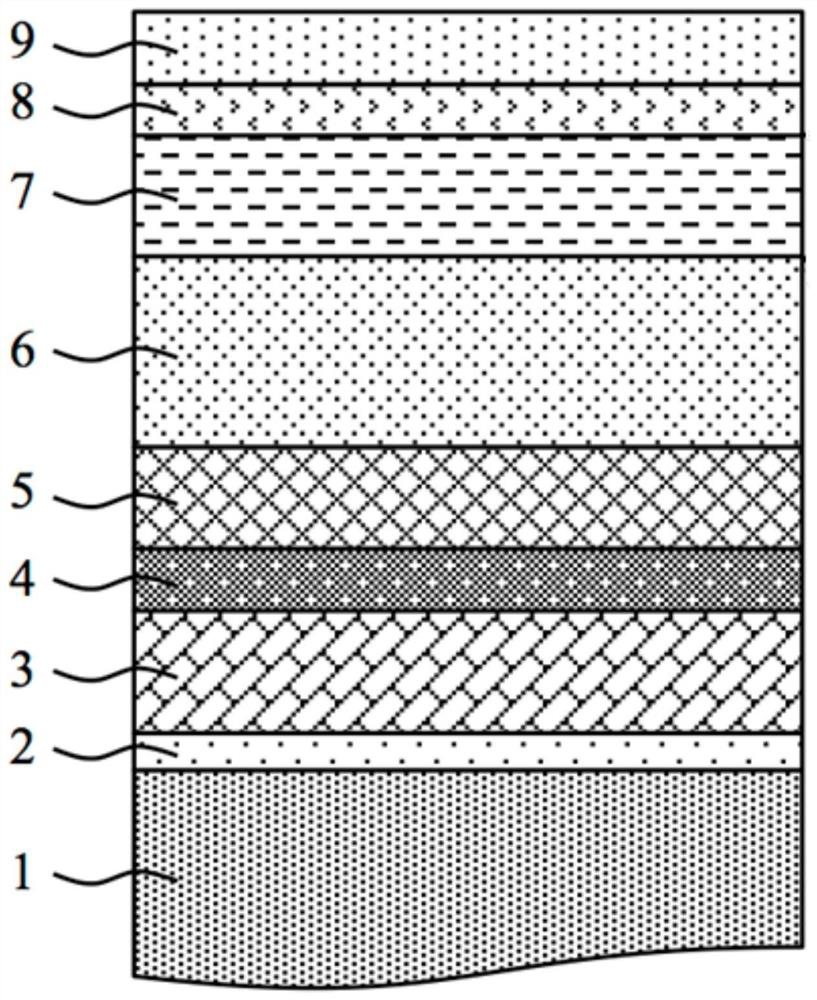

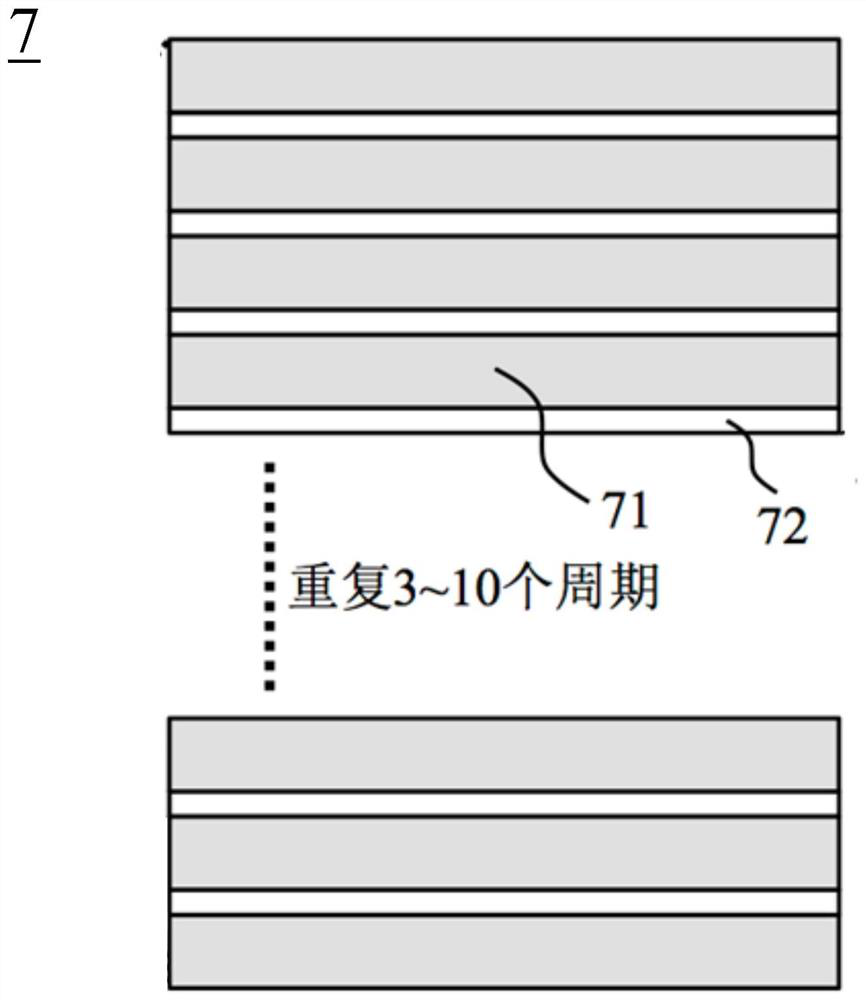

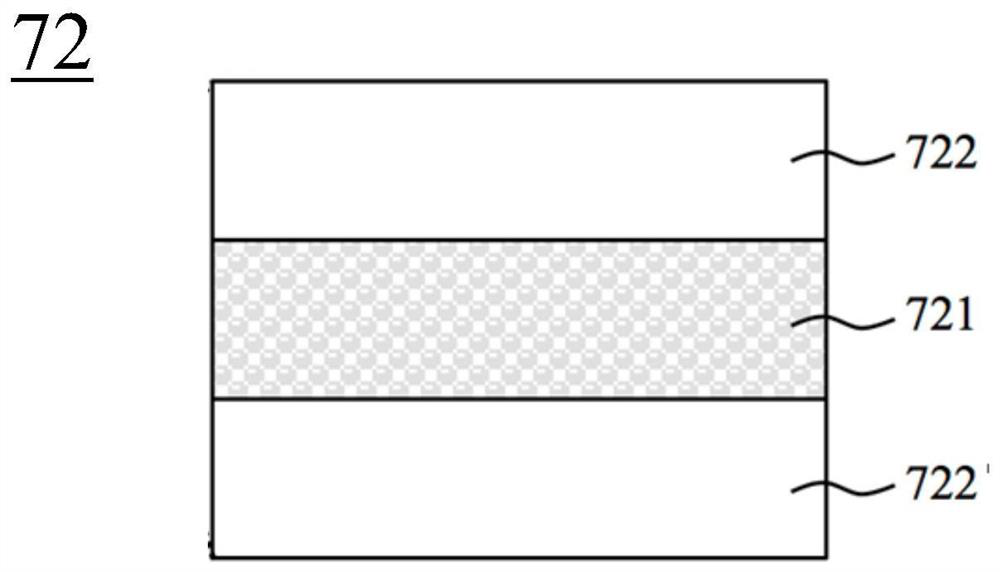

[0052] The LED epitaxial structure of this embodiment includes a sapphire substrate; first grow a 20nm low-temperature AlN buffer layer on the substrate; then use pulsed atomic layer growth to grow a 650nm high-temperature AlN layer; then use 10 cycles of AlN / Al 0.5 Ga 0.5 N (5nm / 2nm) superlattice structure for stress control, while filtering dislocations, and improving the crystal quality of subsequent epitaxial growth; then grow a 1300nm non-doped AlGaN layer; and a 1700nm Si-doped n-type AlGaN layer; and then for 5 cycles of Al 0.4 Ga 0.6 N / Al 0.5 Ga 0.5 N multi-quantum well active light-emitting region, where Al 0.5 Ga 0.5 N barrier thickness is 10nm, Al 0.4 Ga 0.6 The thickness of the N well layer is 3nm, and the middle 1nm area of the well layer is 3nm doped with Mg; finally, 10nm of Mg doped p-type Al is grown. 0.6 Ga 0.4 an N electron blocking layer; and a 150nm p-type GaN layer. In the MOCVD epitaxial growth process, trimethylaluminum (TMAl) and trimethylg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com