Hydroximic acid-alkyl sulfuric acid multi-ligand metal complex collecting agent as well as preparation method and application thereof

A metal complex and alkyl sulfuric acid technology, which is applied in the field of hydroxamic acid-alkyl sulfuric acid multi-ligand metal complex collectors and flotation collectors, can solve the separation of tungsten-containing minerals and calcium-containing gangue minerals Difficulties in roughing and beneficiation, difficult separation in roughing and beneficiation, and large amount of sodium silicate inhibitor, so as to improve the grade of concentrate and the recovery rate of flotation operations, which is conducive to large-scale production and application, and has the effect of strong selective collection capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

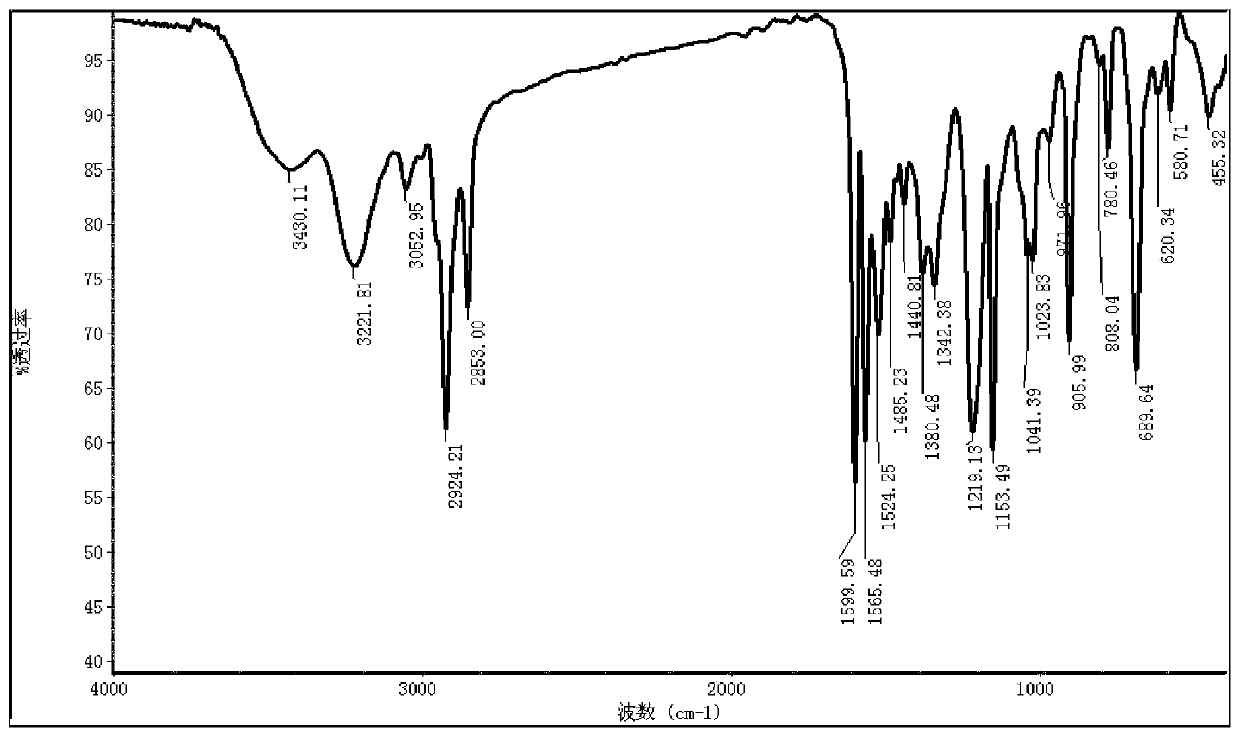

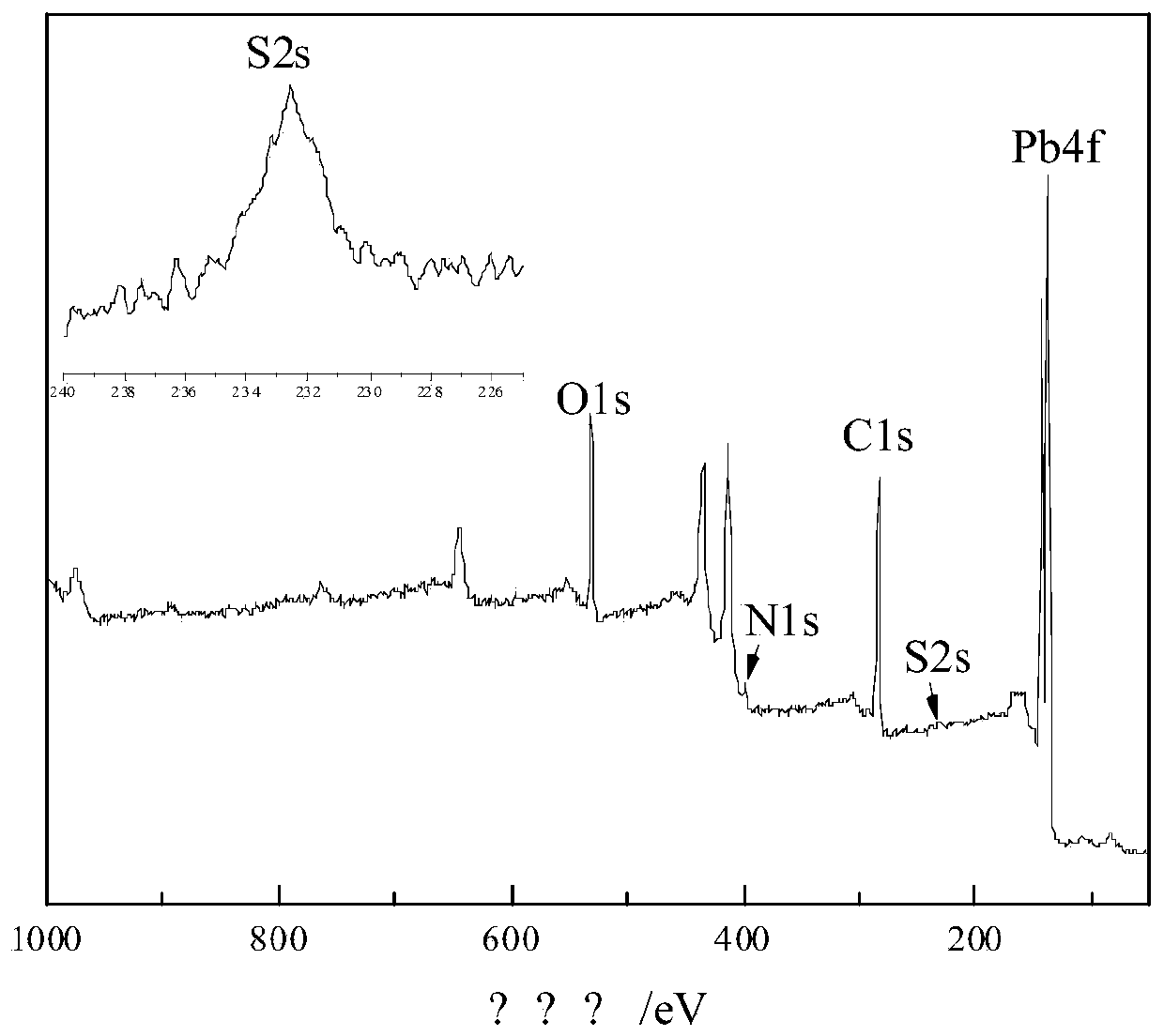

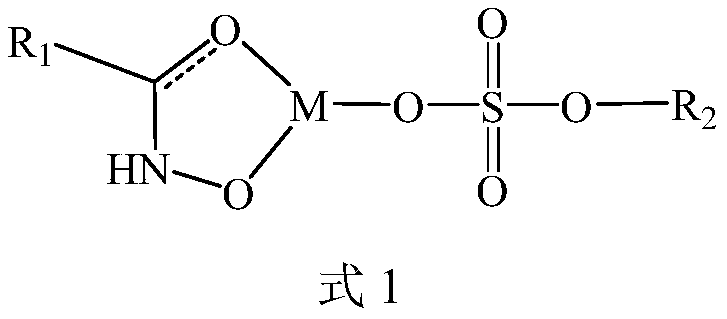

[0052] Weigh 0.001mol of benzohydroxamic acid and put it into a 500mL flask, add 300mL of methanol as a solvent, add 0.0002mol of ethyl acetate after complete dissolution, then add sodium hydroxide to adjust the pH value to 9.0, and stir and react at room temperature for 30min. Obtain hydroxamate; hydroxamate and sodium lauryl sulfate are added in the flask according to the molar mass ratio of 1:1, add glycerol to make its mass concentration 35%, then be placed in a constant temperature water bath, use a magnet Stir and heat to 90°C and react for 20 minutes. The obtained liquid is recrystallized three times after rotary evaporation to obtain a solid; add the obtained solid to the flask, and prepare a mixed liquid of water and methanol according to the volume ratio of water and methanol at 6:1 and add it to the flask In the method, the mass percentage concentration of the solid in the mixed solution of water and methanol is 40%, and the hydroxamic acid-alkylsulfuric acid complex...

Embodiment 2

[0057] Weigh 0.002mol propyl hydroxamic acid into a 500mL flask, add 300mL methanol as solvent, add 0.0004mol ethyl acetate after complete dissolution, then add sodium hydroxide to adjust the pH value to 8.5, and stir the reaction at room temperature for 40min. Obtain hydroxamate; Hydroxamate and n-octadecyl sodium sulfate are added in the flask according to the molar mass ratio of 1:1, add glycerol to make its mass concentration 40%, then place it in a constant temperature water bath, use a magnet Stir and heat to 100°C and react for 15 minutes. The obtained liquid is recrystallized three times after rotary evaporation to obtain a solid; add the obtained solid to the flask, prepare a mixed liquid of water and methanol according to the volume ratio of water and methanol at 8:1 and add it to the flask In the method, the mass percentage concentration of the solid in the mixed solution of water and methanol is 35%, and the hydroxamic acid-alkylsulfuric acid complex micelles are ob...

Embodiment 3

[0062] Weigh 0.001mol salicylic hydroxamic acid into a 500mL flask, add 300mL methanol as a solvent, add 0.0002mol ethyl acetate after complete dissolution, then add sodium hydroxide to adjust the pH value to 9.0, and stir the reaction at room temperature for 25min to obtain hydroxy Hydroxamate; hydroxamate and sodium tetradecyl sulfate are added in the flask according to the molar mass ratio of 1:1, add glycerol to make its mass concentration 42%, then place it in a constant temperature water bath, stir and Heating to 85°C and reacting for 15 minutes, the obtained liquid was recrystallized three times after rotary evaporation to obtain a solid; the obtained solid was added to a flask, and a mixed liquid of water and methanol was prepared according to the volume ratio of water and methanol at 7:1 and added to the flask. The mass percentage concentration of the solid in the mixed solution of water and methanol is 35%, and the hydroxamic acid-alkylsulfuric acid complex micelles a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com