Silole derivative, preparation method and applications thereof, and photoluminescence lubricating grease

A technology of derivatives and grease, applied in the field of silole derivatives with luminescent properties, to achieve the effect of excellent photoluminescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

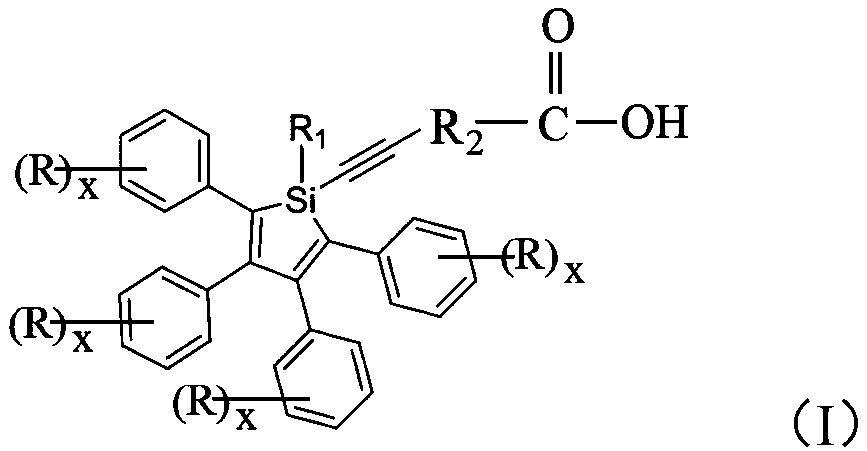

AI Technical Summary

Problems solved by technology

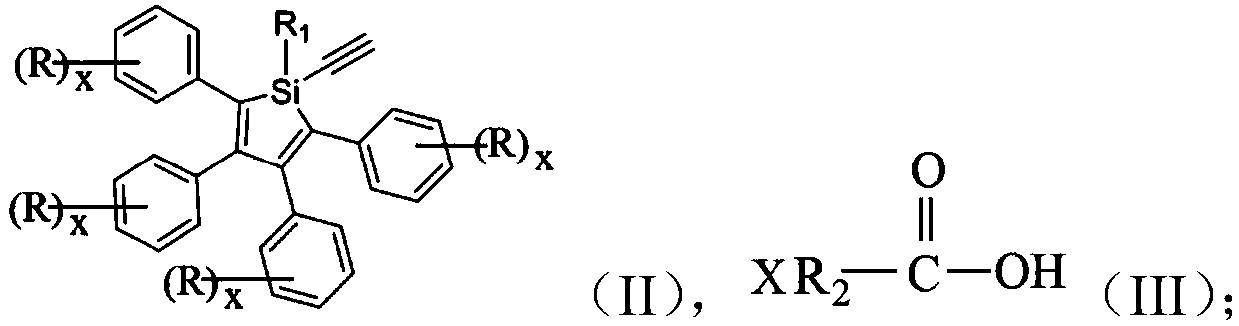

Method used

Image

Examples

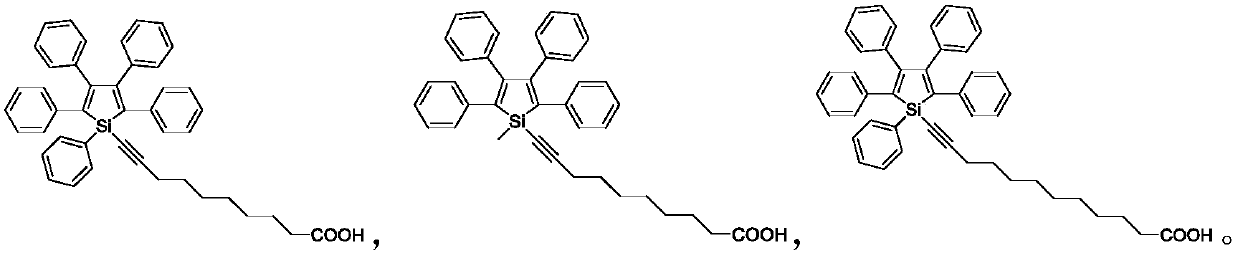

Embodiment 1

[0047] Add 487mg (1mmol) 1-alkynyl-1,2,3,4,5-pentaphenylsilole, 268mg (1.2mmol) 8-bromooctanoic acid, 19mg (0.1mmol) cuprous iodide to a 100mL Schlenk reaction flask , 26mg (0.1mmol) triphenylphosphine, under the protection of nitrogen, add 23mg (0.02mmol) tetrakistriphenylphosphine palladium, 30mL tetrahydrofuran / triethylamine (2 / 1, v / v), react at room temperature for 48 hours. After the reaction was finished, filter and spin the filtrate to dryness, use dichloromethane / methanol (20 / 1, v / v) mixed solvent as eluent to separate and purify the product by column chromatography to obtain 450 mg of yellow solid product. The rate is 72%. The NMR results of the product are: 1 HNMR (400MHz, CDCl 3 ),δ(TMS,ppm):7.78(m,2H),7.34(m,3H),7.13–6.87(m,20H),2.55(m,2H),2.18(m,2H),1.54(m, 2H),1.42(m,2H),1.32–1.26(m,6H); MS(MALDI-TOF):m / z calcd:628.3[M] + , found: 628.3.

[0048] The reaction formula of embodiment 1 is as follows:

[0049]

Embodiment 2

[0051] Add 425 mg (1 mmol) 1-methyl-1-ynyl-2,3,4,5-tetraphenylsilole, 268 mg (1.2 mmol) 8-bromooctanoic acid, 19 mg (0.1 mmol) iodine to a 100 mL Schlenk reaction flask Cuprous chloride, 26mg (0.1mmol) triphenylphosphine, under nitrogen protection, add 23mg (0.02mmol) tetrakistriphenylphosphine palladium, 30mL tetrahydrofuran / triethylamine (2 / 1, v / v), react at room temperature 48 hours. After the reaction, filter and spin the filtrate to dryness, use dichloromethane / methanol (20 / 1, v / v) mixed solvent as eluent to separate and purify the product by column chromatography to obtain 390 mg of yellow solid product, product The rate is 69%. The NMR results of the product are: 1 H NMR (400MHz, CDCl 3 ), δ(TMS,ppm):7.14–6.85(m,20H),2.56(m,2H),2.22(m,2H),1.55(m,2H),1.38(m,2H),1.33–1.26( m,6H),0.22(s,3H); MS(MALDI-TOF):m / z calcd:566.3[M] + , found: 566.3.

[0052] The reaction formula of embodiment 2 is as follows:

[0053]

Embodiment 3

[0055] 145 grams of PAO10 base oil and 44.39 grams of octadecylamine were mixed and heated to 60°C in a reactor, and 2.5 grams of 1-methyl-1-(9-carboxynonynyl)-2 prepared in Example 2 , Dissolve 3,4,5-tetraphenylsilole in 25 grams of toluene and add to the reaction kettle, mix 145 grams of PAO10 base oil and 20.61 grams of MDI and heat to 60°C, and add it to the reaction kettle after the MDI is completely dissolved , heat up to 80°C for 30 minutes, continue to heat up to 210°C, then add 145 grams of PAO10 base oil and cool to about 100°C, add 10g of molybdenum dibutyldithiocarbamate to grind into fat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com