Assistant composition, linear medium density polyethylene composition and preparation method thereof, and polyethylene rotational molding product

A composition and polyethylene technology, applied in the field of polyethylene rotomolding products, can solve the problems of limited source of rotomolding raw materials, insufficient strength, yellowing of products, etc., and achieve good anti-ultraviolet light aging resistance, improved fluidity, Stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

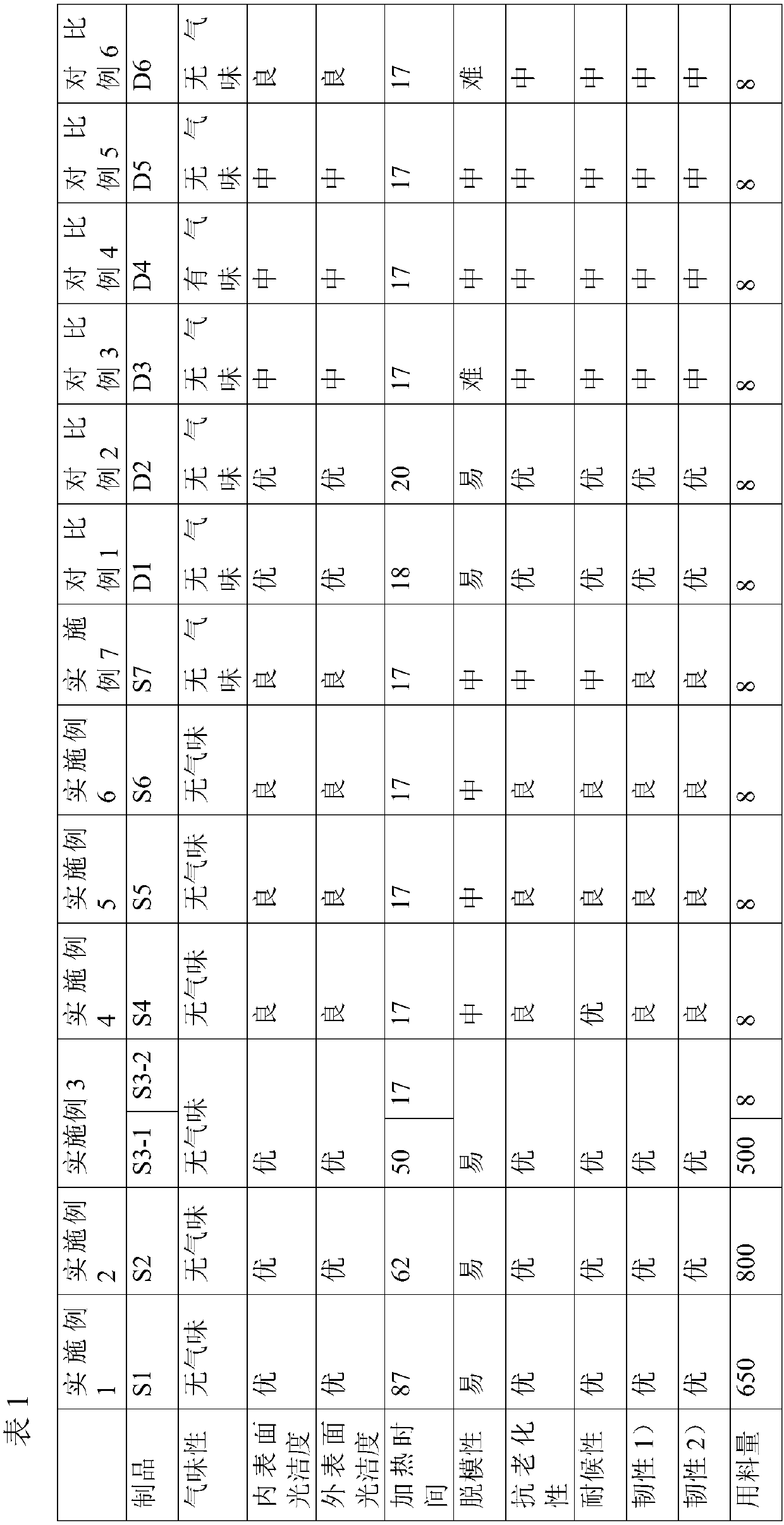

Examples

Embodiment approach

[0042] According to a preferred embodiment of the present invention, the additive composition contains antioxidant 1076, antioxidant 168, zinc stearate, N, N-dihydroxyethyl octadecylamine, light stabilizer UV944, light Stabilizer UV622, and based on the total amount of the composition, the respective contents are 10-20% by weight, 10-20% by weight, 5-10% by weight, 5-10% by weight, 25-45% by weight and 20% by weight -40% by weight. Adopting the auxiliary agent composition in this preferred mode can further improve the release performance, rigidity-toughness balance and weather resistance of the product.

[0043] The second aspect of the present invention provides a linear medium density polyethylene composition, wherein the linear medium density polyethylene composition comprises: based on the total weight of the linear medium density polyethylene composition, containing 97-99.9 parts by weight of linear Medium-density polyethylene and 0.1-3 parts by weight of the above-menti...

specific Embodiment approach

[0047] According to a specific embodiment of the present invention, the method for preparing the linear polymedium density ethylene composition may comprise the following steps:

[0048] The first step: prepared by the Unipol gas phase process, the melt index is 4.6-5.6g / ml and the density is 0.932-0.938g / cm at 190°C under a load of 2.16kg 3 linear medium density polyethylene powder.

[0049] Second step: the obtained linear medium density polyethylene is blended with the auxiliary agent composition of the present invention, and extruded and granulated to make the linear medium density polyethylene composition.

[0050] Before extrusion granulation, pigments can be added or not according to the needs of downstream customers. Because the phthalocyanine blue pigment is not only bright in color and strong in tinting strength, but also resistant to light and heat, it is more beneficial for large-scale products to be placed outdoors for a long time, so it is preferable to add phth...

Embodiment 1

[0075] (1) Preparation of additive composition

[0076] Based on the total weight of the additive composition, the antioxidant 1076 with a content of 10% by weight, the antioxidant 626 with a content of 20% by weight, the zinc stearate with a content of 6% by weight, and a content of 10% by weight % antistatic agent GMS, UV2020 with a content of 25% by weight, and UV622 with a content of 29% by weight were mixed to obtain an additive composition.

[0077] (2) Preparation of linear medium density polyethylene composition

[0078] (2.1) Prepared by the Unipol gas phase process, the melt index at 190°C under a load of 2.16kg is 5.0g / 10min, and the density is 0.934g / cm 3 Linear medium density polyethylene (powder).

[0079] (2.2) Based on the total weight of the linear medium density polyethylene composition, the linear medium density polyethylene obtained in the step (2.1) of 98 parts by weight and the auxiliary agent composition obtained in the step (1) of 2 parts by weight Car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com