Fabric of photo-thermal conversion material with core-shell structure and preparation method thereof

A technology of light-to-heat conversion materials and core-shell structure, which is applied in the fields of plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problem that the durability of washing resistance and light-to-heat conversion performance is difficult to guarantee, and the adhesion between fibers and copper sulfide nanoparticles Focus on problems such as poor strength and uniformity, affecting material properties, etc., to achieve stable light-to-heat conversion ability, improve light-to-heat conversion ability, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a fabric with a core-shell structured light-to-heat conversion material, the steps of which are as follows:

[0038] 1. Preparation of copper sulfide nanoparticles:

[0039] Add 1.6ml 50mM sodium sulfide nonahydrate solution to 20ml 4mM copper chloride dihydrate solution at room temperature, stir rapidly for 2 minutes, then add 0.9g trisodium citrate to the mixed solution, and let it stand quickly Heat for 30min, centrifuge at 12000rpm for 30min, discard the supernatant, add deionized water to the precipitate and resuspend, centrifuge at 12000rpm for 30min, repeat twice, dry and grind.

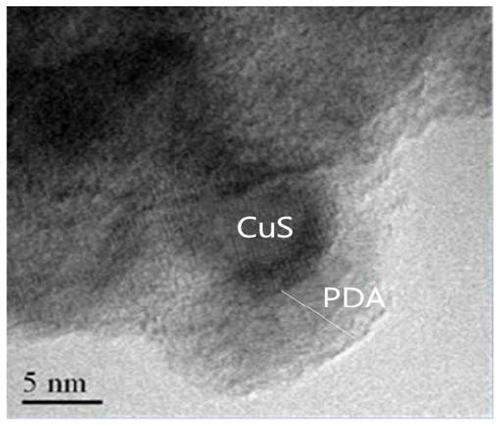

[0040] 2. Preparation of dopamine-coated copper sulfide nanoparticles:

[0041] Add 0.122g of tris to 100ml of water to obtain a Tris solution, adjust the pH value of the solution to 8.5 with 0.1M hydrochloric acid, then add 0.1-10g of dopamine hydrochloride to the solution, stir rapidly, and add 0.5g of copper sulfide The powder was dispersed in freshly prepared ...

Embodiment 2

[0047] A method for preparing a fabric with a core-shell structured light-to-heat conversion material, the steps of which are as follows:

[0048] 1. Preparation of copper sulfide nanoparticles:

[0049] Add 1.6ml 50mM sodium sulfide nonahydrate solution to 20ml 4mM copper chloride dihydrate solution at room temperature, stir rapidly for 2 minutes, then add 0.9g trisodium citrate to the mixed solution, stir rapidly for 2 minutes Finally, the solution was dark brown and a black precipitate was formed at this time. Then stand and heat in a water bath at 80°C for 30 minutes, centrifuge at 12,000 rpm for 30 minutes, discard the supernatant, add deionized water to resuspend, and centrifuge at 12,000 rpm for 30 minutes, repeat twice, dry and grind.

[0050] 2. Preparation of dopamine-coated copper sulfide nanoparticles:

[0051] Add 0.122g of tris to 100ml of water to obtain a Tris solution, adjust the pH value of the solution to 8.5 with 0.1M hydrochloric acid, then add 0.1-10g o...

Embodiment 3

[0057] A method for preparing a fabric with a core-shell structured light-to-heat conversion material, the steps of which are as follows:

[0058] 1. Preparation of copper sulfide nanoparticles:

[0059] Add 1.6ml 50mM sodium sulfide nonahydrate solution to 20ml 4mM copper chloride dihydrate solution at room temperature, stir rapidly for 2 minutes, then add 0.9g trisodium citrate to the mixed solution, stir rapidly for 2 minutes After a few minutes, the solution was now dark brown and a black precipitate formed. Then stand and heat in a water bath at 80°C for 30 minutes, centrifuge at 12,000 rpm for 30 minutes, discard the supernatant, add deionized water to resuspend, and centrifuge at 12,000 rpm for 30 minutes, repeat twice, dry and grind.

[0060] 2. Preparation of dopamine-coated copper sulfide nanoparticles:

[0061] Add 0.122g of tris to 100ml of water to obtain a Tris solution, adjust the pH of the solution to 8.5 with 0.1M hydrochloric acid, then add 0.1-10g of dopam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com