Porous carbon adsorbent based on polyethylene microplastics and preparation method and application thereof

A technology of microplastics and polyethylene, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of large chromaticity, refractory degradation, biological toxicity, etc., and achieve simple operation and high added value. Effect of conversion, strong removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Select PE microplastic powder as the raw material, weigh 3 g and disperse it in a round-bottomed flask filled with 150 mL of concentrated sulfuric acid with a concentration of 98%, heat and reflux with a heating mantle for 8 h, and then naturally cool to room temperature to obtain a black liquid;

[0027] The above black liquid was slowly added dropwise into a solution with a ratio of 40 g NaOH / 200 mL water, and the dropping process was carried out in an ice-water bath to ensure that the temperature of the neutralization reaction system was lower than 40 °C.

[0028] The product obtained after neutralization with alkali was centrifuged in a centrifuge at 5000 r / min for 5 min, the obtained solid was washed with ultrapure water, and centrifuged until all the solids were completely dissolved in water, that is, the centrifugation could not separate the solid from the liquid.

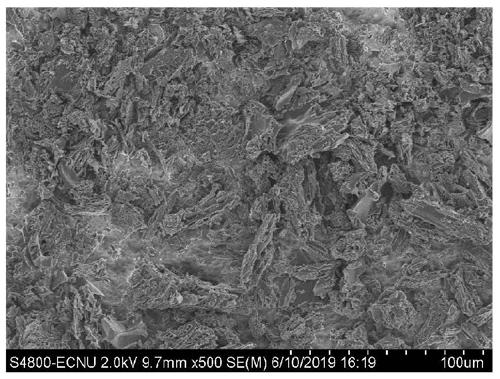

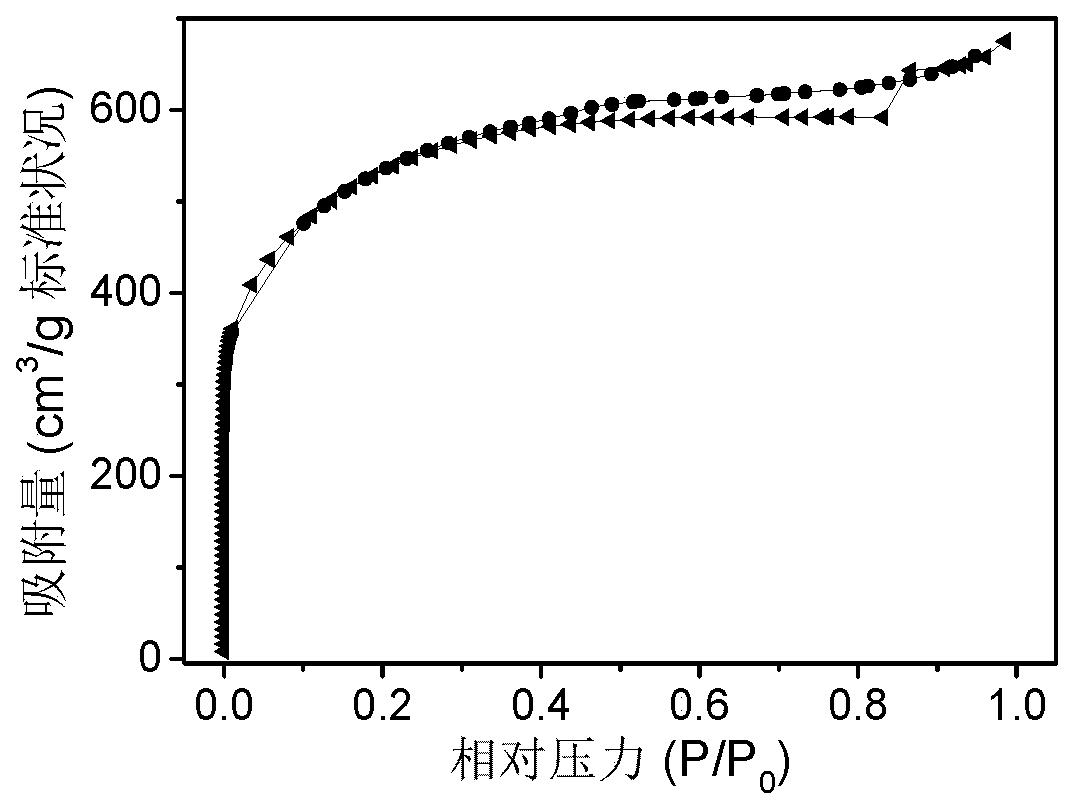

[0029] The product obtained in the previous step was frozen and dried in a freeze dryer to obtain s...

Embodiment 2

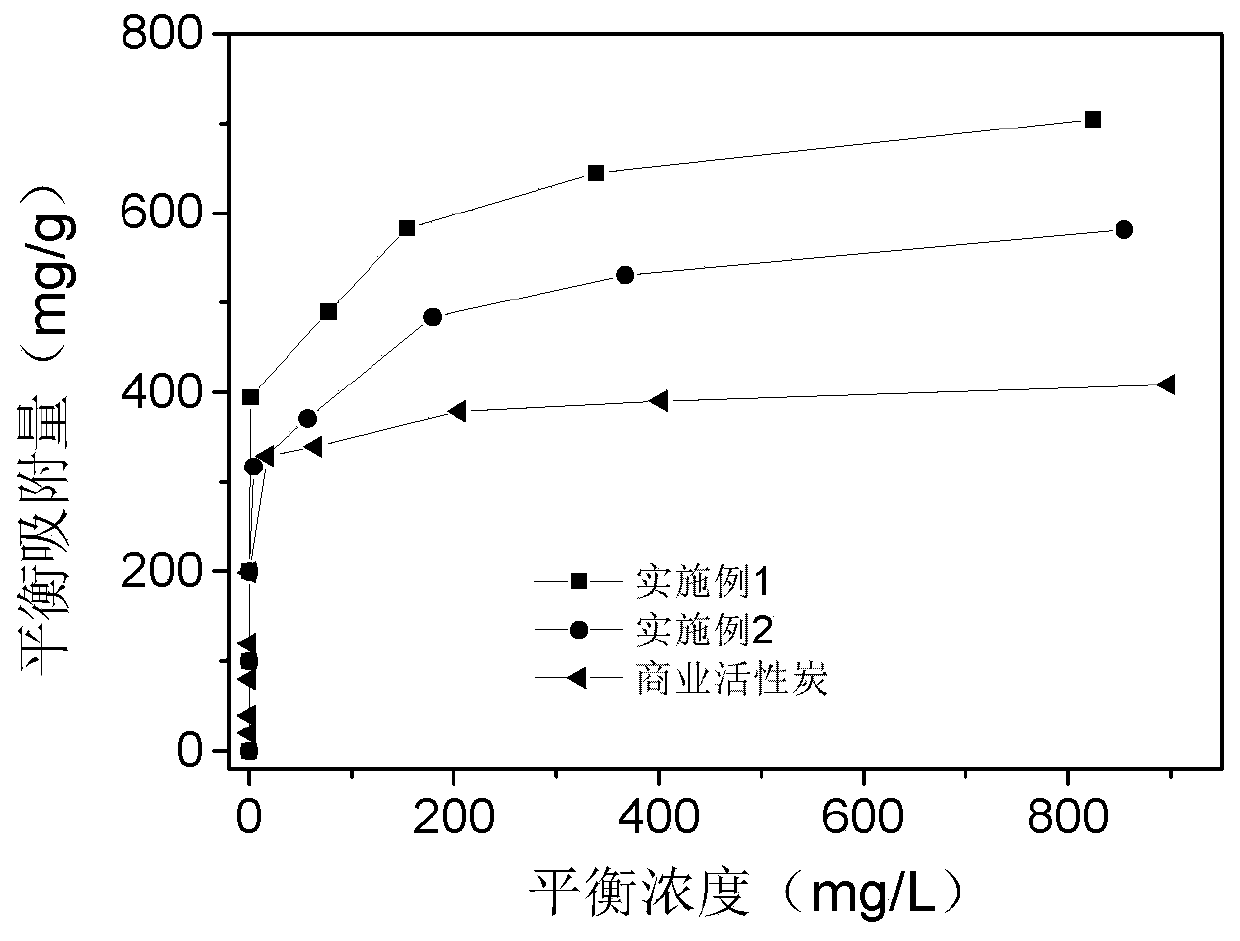

[0033] Waste PE mulch was selected as raw material, cut into microplastic fragments of 5 mm × 5 mm, and porous carbon adsorbent was prepared according to the method in Example 1. The operation of the adsorption experiment was the same as in Example 1, and the saturated adsorption capacity of the porous carbon adsorbent to methylene blue could reach 581.1 mg / g.

[0034] The thermodynamic curves of the porous carbon adsorbent prepared in Example 1 and Example 2 of the present invention and commercial activated carbon adsorb methylene blue under the same conditions are as follows image 3 As shown, it can be seen from the figure that the porous carbon adsorbent based on polyethylene microplastics has a much higher removal capacity for methylene blue dye than commercial activated carbon (its maximum adsorption capacity is 408.7 mg / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com