Spiral-wound membrane bioreactor

A technology of bioreactor and roll-type membrane, which is applied in the field of water treatment, can solve the problems of water permeability drop, membrane module contamination, etc., and achieve the effects of recovery of membrane filtration capacity, increase of membrane flux, and reduction of sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

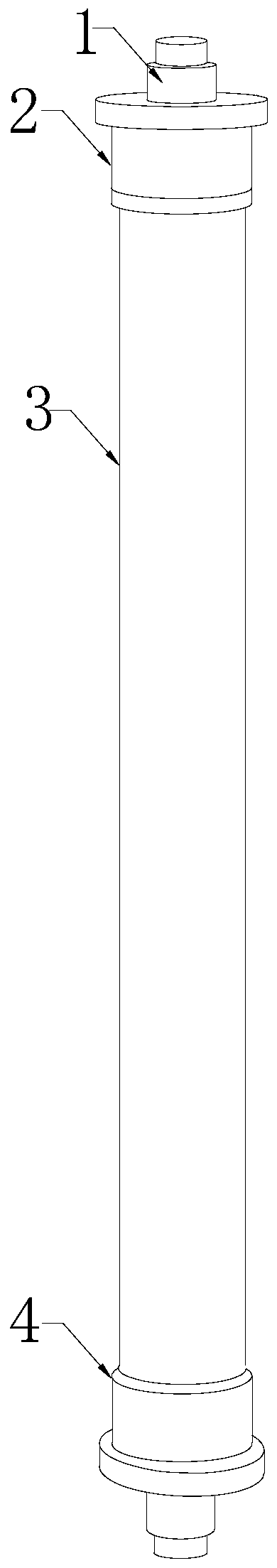

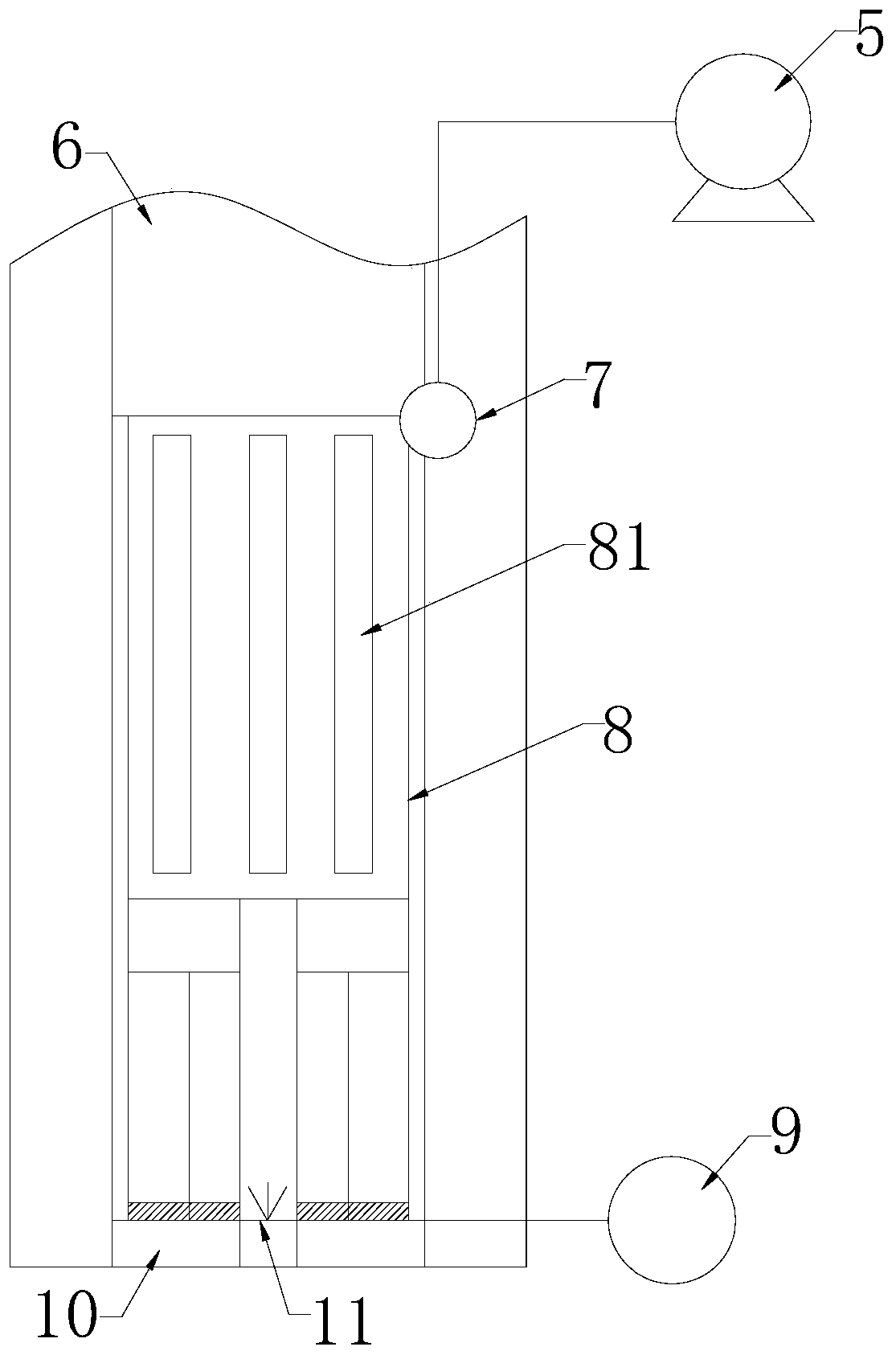

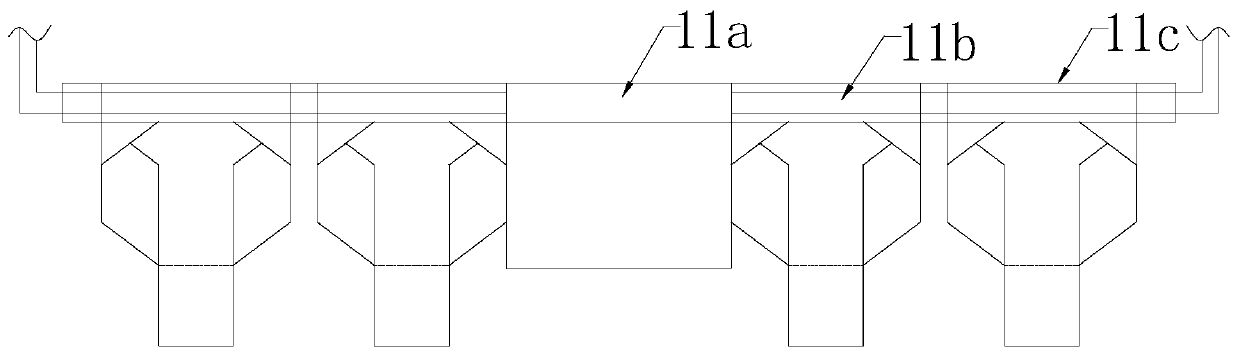

[0028] like Figure 1-Figure 5 As shown, the present invention provides a roll-type membrane bioreactor, the structure of which includes an interface 1, a mold base upper seal 2, a mold base 3, a mold base lower seal 4, a water pump 5, a water outlet 6, a water collection pipe 7, and a membrane module 8. The blower 9, the water inlet 10, and the aeration device 11, the interface 1 is provided with a sealing ring and the upper seal 2 of the mold base, and the lower seal 4 of the mold base are sealed and blocked, and the inside of the mold base 3 is provided with an outlet Water inlet 6, water collection pipe 7, membrane module 8, water inlet 10 and aeration device 11, described water collection pipe 7 is connected with water pump 5, and described aeration device 11 is composed of blower 9, main aeration port 11a, auxiliary aeration port 11b, an aeration disc 11c is formed, the blower 9 is connected to the aeration disc 11c, and the main aeration port 11a and the auxiliary aerat...

Embodiment 2

[0030] like Image 6 As shown, the membrane assembly 8 includes a membrane element 81, a connecting frame 82, a mounting seat 83, and an extrusion seat 84. The membrane elements 81 are distributed in parallel, and the membrane element 81 is fixed on the extrusion seat 84 by a connecting frame 82. , and the two sides of the extrusion seat 84 are installed and fixed with the mounting seat 83, the connecting frame 82 is wave-shaped, and the membrane elements 81 are installed independently, and the airflow generated by the air distribution hole b3 acts on the membrane surface of the membrane element 81 , one end of the blocking member b0 extending out of the aeration disc 11c is connected to the extruding seat 84 with a tie rod, and the connecting frame 82 is wave-shaped, and the connecting frame 82 is symmetrically arranged, and can be aerated at the auxiliary aeration port 11b The radial impact forces generated during the process cancel each other out to a certain extent, ensuri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap