Method for preparing furfuryl alcohol by catalyzing transfer hydrogenation of furfural through non-noble metal-loaded nitrogen-doped carbon

A nitrogen-doped carbon, non-precious metal technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high research and development costs and maintenance costs, and achieve a green reaction system, simple process, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

[0041]Catalyst in Example 8: Co@NC-600, carbonization temperature is 600°C, other conditions are the same as Co@NC-700 in Examples 1 to 7 above; catalyst Co@NC-800 in Example 9, carbonization temperature is 800°C °C, other conditions are the same as those of Co@NC-700 in Examples 1-7 above.

Embodiment 10

[0042] Catalyst in Example 10: Co@NC-700 catalyst hydrothermally synthesized at 100°C, the temperature of hydrothermal synthesis is 100°C, and other conditions are the same as Co@NC-700 in Examples 1-7 above; in Example 11 Catalyst: Co@NC-700 catalyst hydrothermally synthesized at 140°C, the temperature of hydrothermal synthesis is 140°C, and other conditions are the same as Co@NC-700 in Examples 1-7 above.

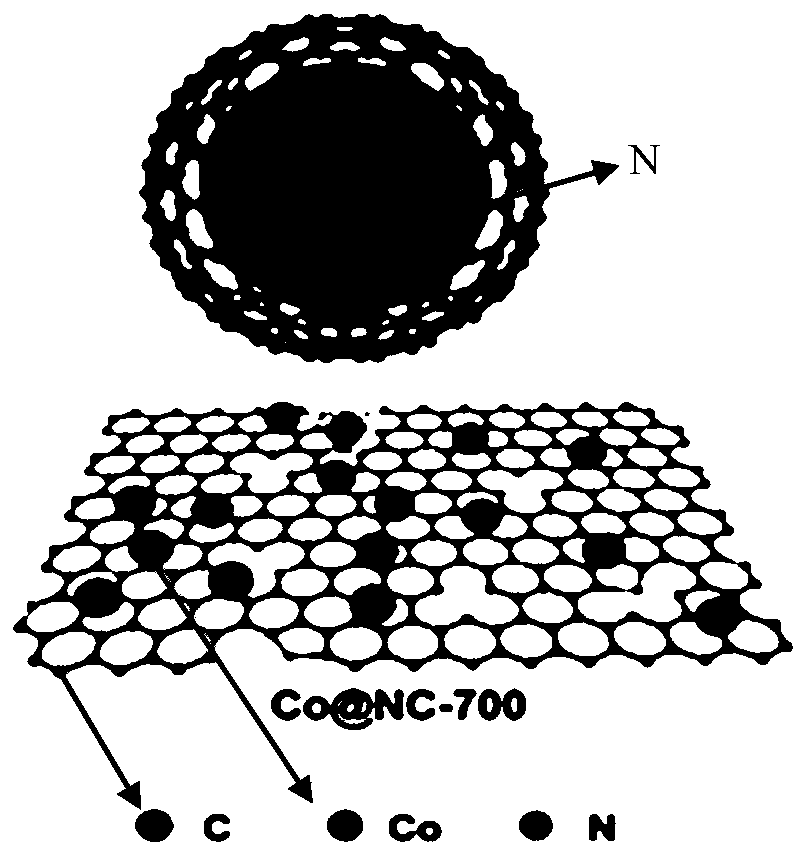

[0043] The structural representation of the catalyst prepared by the present invention is as image 3 shown. SEM image of Co@NC-700 catalyst Figure 4 shown.

Embodiment 1

[0045] Accurately weigh 0.5mmol of furfural, 5mL of isopropanol and 50mg of Co@NC-700 catalyst, place them in a 10ml high-pressure hydrothermal reactor, place them in a stirring heating device at 150°C, stir and heat for 3 hours, cool to room temperature, and filter The obtained liquid mixture was sampled for gas phase analysis, and the conversion rate of furfural was 82%, and the selectivity of furfuryl alcohol was 77%.

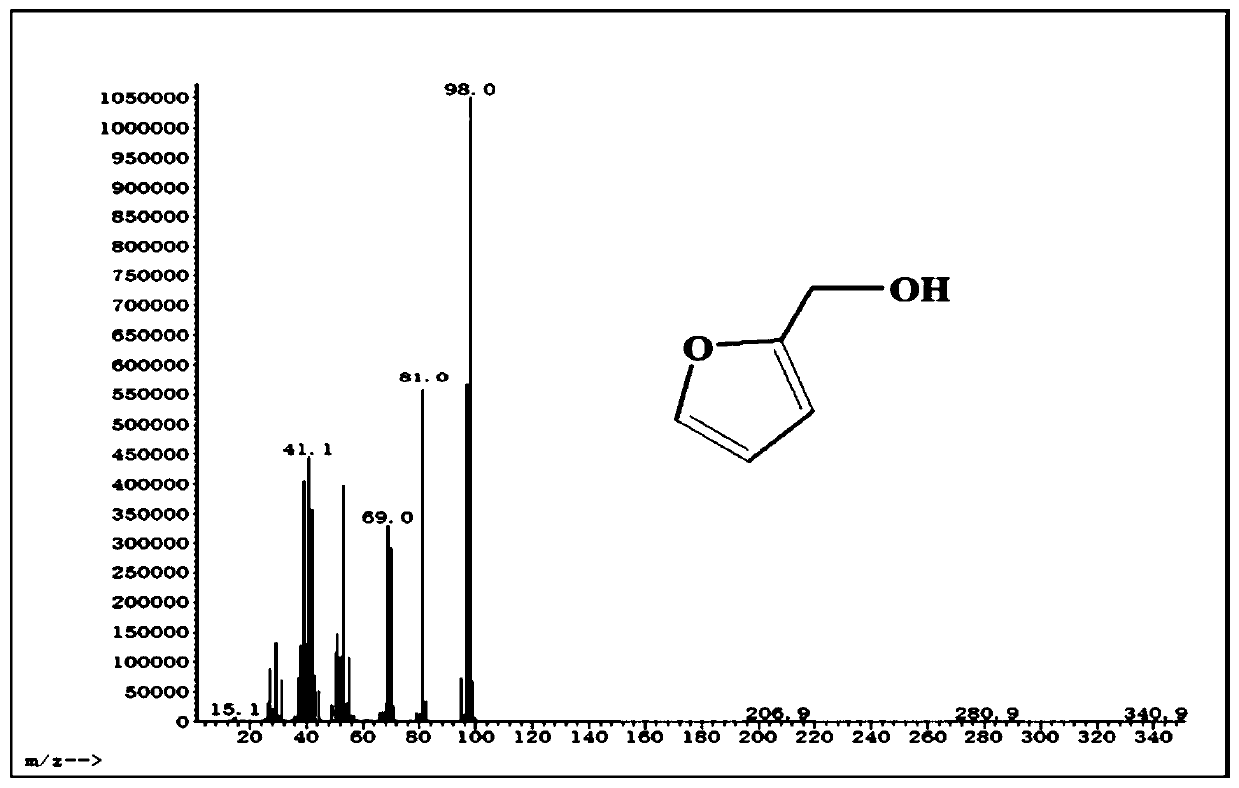

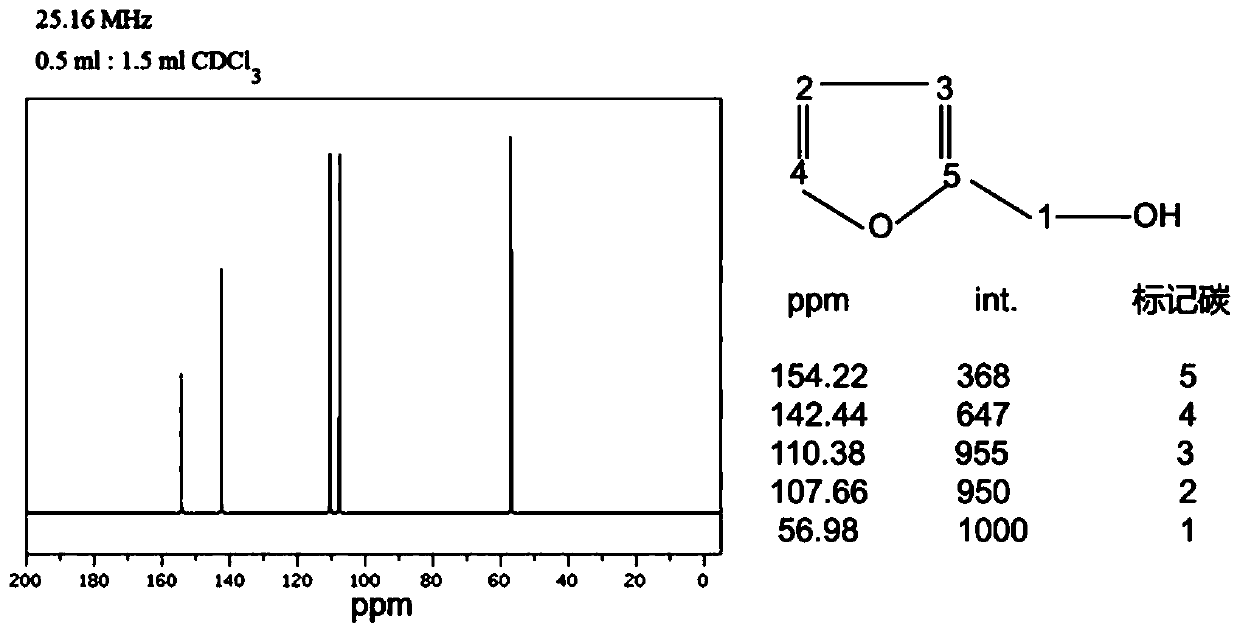

[0046] figure 1 The mass spectrogram of the furfuryl alcohol prepared for Example 1 of the present invention; figure 2 Prepare the nuclear magnetic pattern (NMR) of furfuryl alcohol for the embodiment of the present invention 1 13 CNMR).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com