Transparent halogen-free flame-retardant PC material for UV adhesive curing and preparation method thereof

A transparent and flame retardant technology, applied in the field of transparent halogen-free flame retardant PC materials and their preparation, can solve the problems of uneven distribution of sulfonate flame retardants, affecting the performance of PC materials, poor flame retardant effect, etc. Improve efficiency and bonding effect, good weather resistance, and promote the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

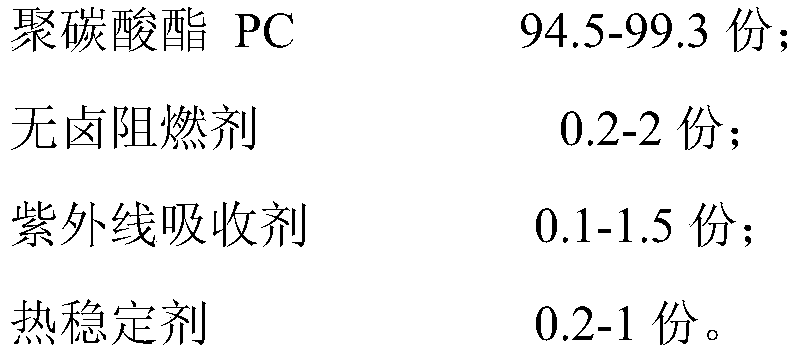

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 96 parts of raw material PC resin, 0.6 part of main flame retardant FR350M, 0.4 part of auxiliary flame retardant SI9805, 0.6 part of UV-1577 and 0.3 part of antioxidant in high-speed mixing Stir in the machine for 3-5min, and dry in an oven;

[0034] (2) The mixture obtained in step (1) is sent into the co-rotating intermeshing twin-screw extruder through the main feed. The extruder screw diameter is 35mm, and the length-to-diameter ratio L / D is 40. It is: 240°C in the first zone, 250°C in the second zone, 255°C in the third zone, 260°C in the fourth zone, 265°C in the fifth zone, 270°C in the sixth zone, 275°C in the seventh zone, the speed of the main machine is 200-300rpm / min, and then melted and extruded , cooling, granulation, and drying to obtain a transparent flame-retardant PC that can be used for UV glue curing.

Embodiment 2

[0036] (1) Weigh 96 parts of raw material PC resin, 0.6 part of main flame retardant FR350M, 0.6 part of auxiliary flame retardant SI9805, 0.6 part of UV-9 and 0.3 part of antioxidant in high-speed mixing Stir in the machine for 3-5min, and dry in an oven;

[0037] (2) The mixture obtained in step (1) is sent into the co-rotating intermeshing twin-screw extruder through the main feed. The extruder screw diameter is 35mm, and the length-to-diameter ratio L / D is 40. It is: 240°C in the first zone, 250°C in the second zone, 255°C in the third zone, 260°C in the fourth zone, 265°C in the fifth zone, 270°C in the sixth zone, 275°C in the seventh zone, the speed of the main machine is 200-300rpm / min, and then melted and extruded , cooling, granulation, and drying to obtain a transparent flame-retardant PC that can be used for UV glue curing.

Embodiment 3

[0039] (1) Take by weight the PC resin of 97 parts of raw materials, the main flame retardant FR350M of 0.5 part, the auxiliary flame retardant SI9805 of 0.5 part, the UV-1577 of 0.3 part and the UV-9 of 0.3 part, mix in high speed Stir in the feeder for 3-5min, and dry in an oven;

[0040] (2) The mixture obtained in step (1) is sent into the co-rotating intermeshing twin-screw extruder through the main feed. The extruder screw diameter is 35mm, and the length-to-diameter ratio L / D is 40. It is: 240°C in the first zone, 250°C in the second zone, 255°C in the third zone, 260°C in the fourth zone, 265°C in the fifth zone, 270°C in the sixth zone, 275°C in the seventh zone, the speed of the main machine is 200-300rpm / min, and then melted and extruded , cooling, granulation, and drying to obtain a transparent flame-retardant PC that can be used for UV glue curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com