Industrial synthesis method for vat blue 6

A synthesis method and finished product technology, applied in the field of dyes, can solve the problems of waste acid discharge, environmental pollution, high consumption of raw materials, high production cost, etc., and achieve the effects of reducing waste acid discharge, better utilization of resources, and quality assurance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

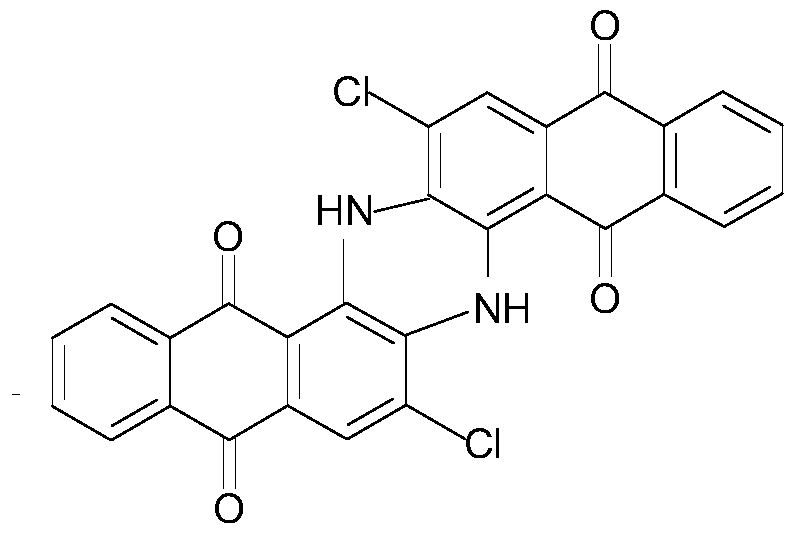

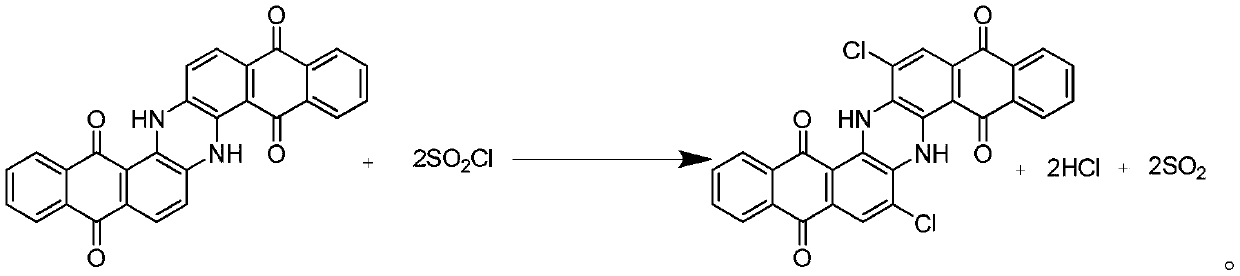

Image

Examples

Embodiment 1

[0032] (1) After testing, the water content in the raw material Vat Blue 4 dry product powdery material is 2%; the amount of chlorobenzene added from the metering tank is 2000L, start stirring, and under stirring conditions, 500Kg of Vat Blue 4 dry product powdery material is once Put in a 3000L condensation pot, heat up the steam to 110-112°C for dehydration for 1 hour, then cool down;

[0033] (2) Cool down to 30-35°C, add 400Kg of sulfuryl chloride dropwise from the metering tank, heat up the material to 80-85°C after adding, keep the temperature for 5 hours, take samples to measure the chlorine content of the material; after the chlorine content is qualified, stop heating;

[0034] (3) Add 500L of water to the reactor to dilute the material, then add sodium hydroxide until the pH of the material is neutralized to 8-10 (the amount of alkali is based on the actual pH);

[0035] (4) Straight through the steam to heat up the material for distillation, the steamed vapor phase i...

Embodiment 2

[0038] (1) After testing, the water content in the raw material Vat Blue 4 dry product powdery material is 0.5%; the amount of o-dichlorobenzene added from the metering tank is 1500L, and the stirring is started, and the dry product powdery material of Vat Blue 4 is mixed under stirring conditions Put 500Kg into a 3000L condensation pot at a time, heat up to 100-110°C, stir evenly, and cool down;

[0039] (2) Cool down to 30-35°C, add 750Kg of sulfuryl chloride dropwise from the metering tank, heat up the material to 85-90°C after adding, keep the temperature for 5 hours, take samples to measure the chlorine content of the material; after the chlorine content is qualified, stop heating;

[0040] (3) Add 1000L of supernatant water reclaimed in step (4) to the reaction kettle to dilute the material, then add sodium carbonate until the pH of the material is neutralized to 7~9 (the amount of alkali is based on the actual pH);

[0041] (4) Straight through the steam to heat up the ...

Embodiment 3

[0044] (1) After testing, the water content in the raw material Vat Blue 4 dry product powdery material is 1.0%; the amount of chlorobenzene added from the metering tank is 1200L, start stirring, and under stirring conditions, 500Kg of Vat Blue 4 dry product powdery material is once Put in a 2000L condensation pot, heat up the steam to 110-112°C for dehydration for 1 hour, then cool down;

[0045] (2) Cool down to 30-35°C, add 450Kg of sulfuryl chloride dropwise from the metering tank, heat up the material to 75-85°C after adding, keep the temperature for 5 hours, take samples to measure the chlorine content of the material; after the chlorine content is qualified, stop heating;

[0046] (3) Add 750L of water to the reactor to dilute the material, then add sodium hydroxide until the pH of the material is neutralized to 8-10 (the amount of alkali is based on the actual pH);

[0047] (4) Straight through the steam to heat up the material for distillation, the steamed vapor phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com