A kind of slurry preparation method of metal element-containing lithium-sulfur battery cathode material

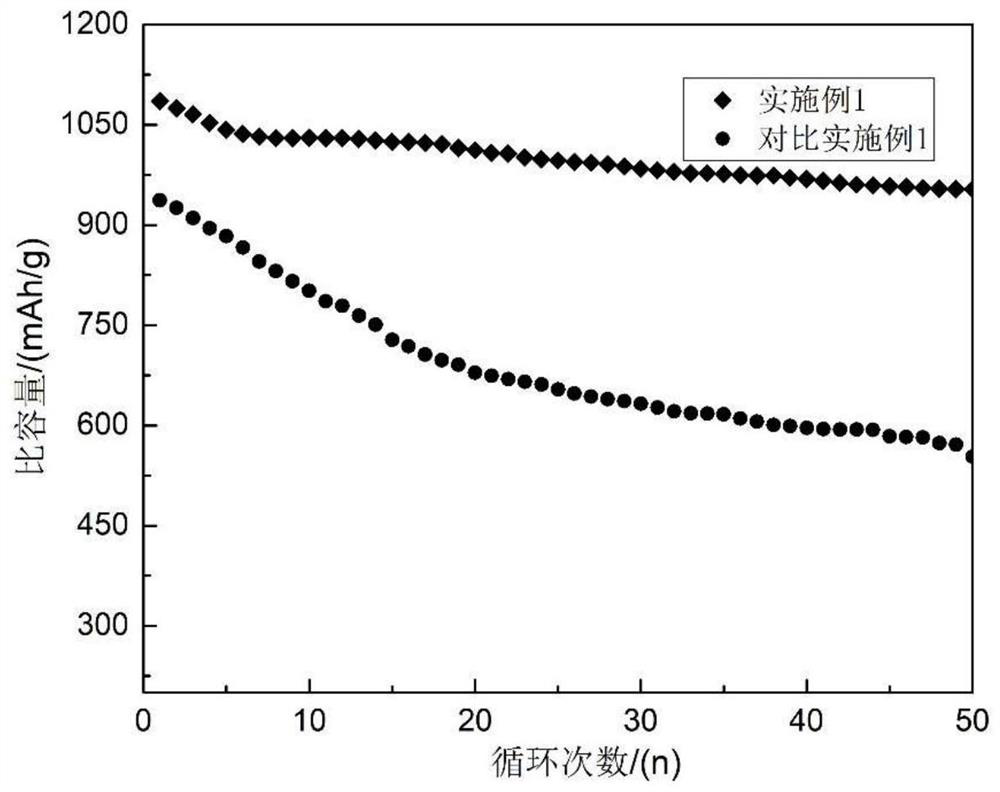

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of high time cost, low load capacity, affecting capacity performance, etc., to reduce the loss of active material sulfur, Effect of improving cycle stability and suppressing volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a slurry of a lithium-sulfur battery positive electrode material containing metal elements, comprising the following steps:

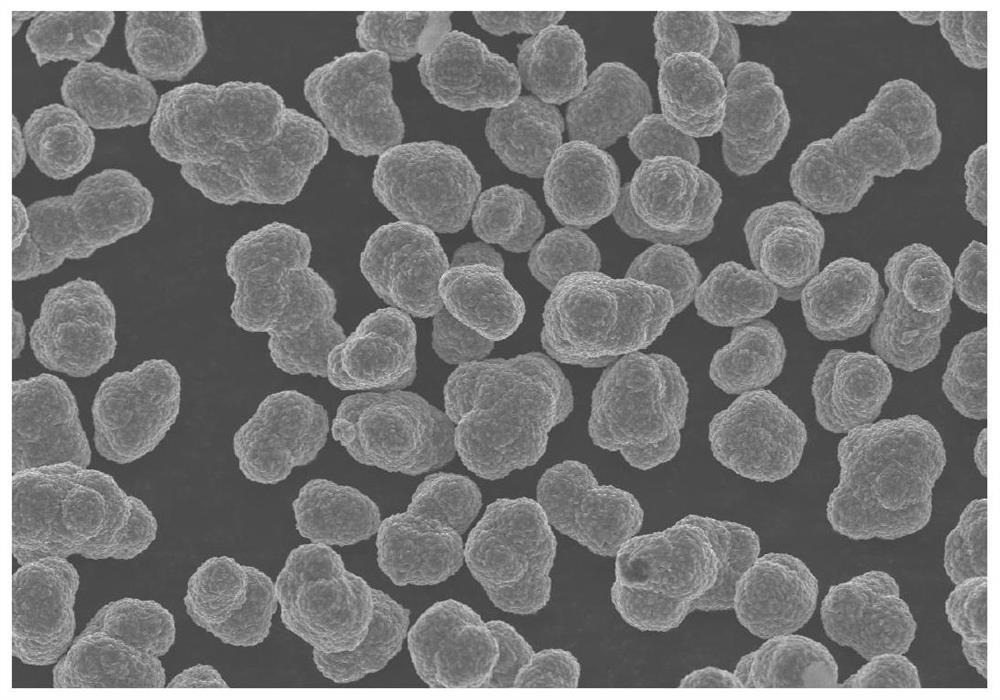

[0029] (1) Add 95.5% sulfur / vanadium nitride composite material and 2% superconducting carbon black into the mixer according to the powder ratio and stir evenly, the stirring speed is 28rpm, and the stirring time is 60min, so that the superconducting carbon black is uniform Coated on the surface of the sulfur / metal nitride composite to form a core-shell structure;

[0030] (2) Continue to add 2% PVDF and 0.5% HPMA to the mixer, the stirring speed is 28rpm, and the stirring time is 60min;

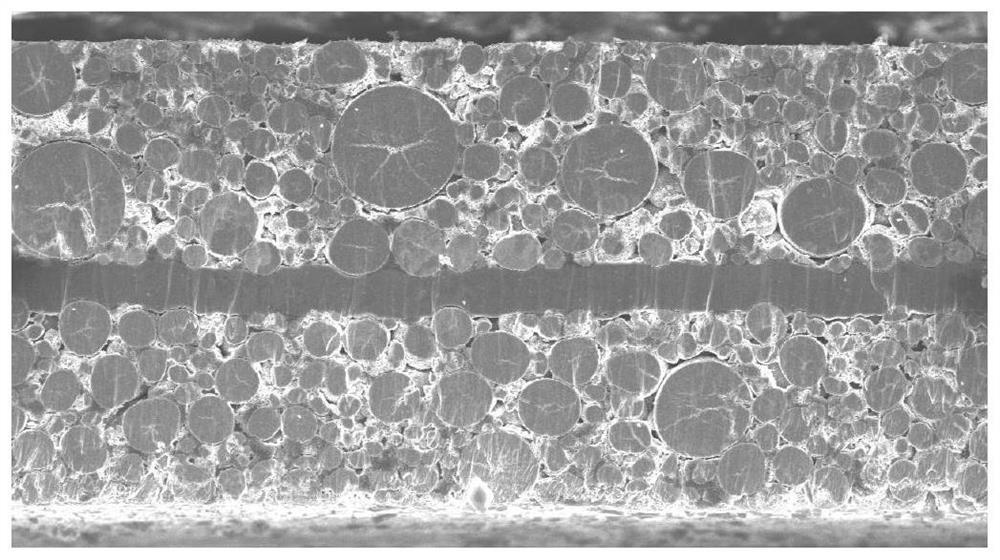

[0031] (3) Pour the mixed powder obtained in step (2) into a blender, then add a certain amount of N-methylpyrrolidone to continue stirring, the revolution rate is 30rpm, the autorotation rate is 2800rpm, and the stirring time is 180min. Finally, the solid content is 72% positive electrode slurry.

Embodiment 2

[0033] A method for preparing a slurry of a lithium-sulfur battery positive electrode material containing metal elements, comprising the following steps:

[0034] (1) According to the powder ratio, add 90% iron sulfide and 5% superconducting carbon black into the mixer and stir evenly. The stirring speed is 31rpm and the stirring time is 90min, so that the superconducting carbon black is evenly coated on the metal sulfide A core-shell structure is formed on the surface of the object;

[0035] (2) Continue to add 3% acrylate and 2% polyethylene glycol 200 into the mixer to continue stirring, the stirring rate is 25rpm, and the stirring time is 75min;

[0036] (3) Pour the mixed powder obtained in step (2) into a blender, then add a certain amount of propanol and continue to stir, the revolution rate is 25rpm, the autorotation rate is 3200rpm, and the stirring time is 200min, and finally a positive electrode with a solid content of 65% is obtained slurry.

Embodiment 3

[0038] A method for preparing a slurry of a lithium-sulfur battery positive electrode material containing metal elements, comprising the following steps:

[0039] (1) According to the powder ratio, add 80% sulfur / titanium dioxide composite material and 10% superconducting carbon black into the mixer and stir evenly, the stirring speed is 25rpm, and the stirring time is 40min, so that the superconducting carbon black is evenly coated Formation of a core-shell structure on the sulfur / metal organic polymer surface;

[0040] (2) Continue to add proportioning 4% SBR and 6% CMC to the mixer to continue stirring, the stirring rate is 34rpm, and the stirring time is 55min;

[0041] (3) Pour the mixed powder obtained in step (2) into the blender, then add a certain amount of deionized water to continue stirring, the revolution rate is 36rpm, the autorotation rate is 4100rpm, the stirring time is 150min, and finally the solid content is 50%. positive electrode slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com