Cathode active material for secondary battery, preparation method therefor, and lithium secondary battery comprising same

A positive electrode active material and secondary battery technology, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of crystal structure instability, surface stability degradation, service life reduction, etc., and achieve excellent structural stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

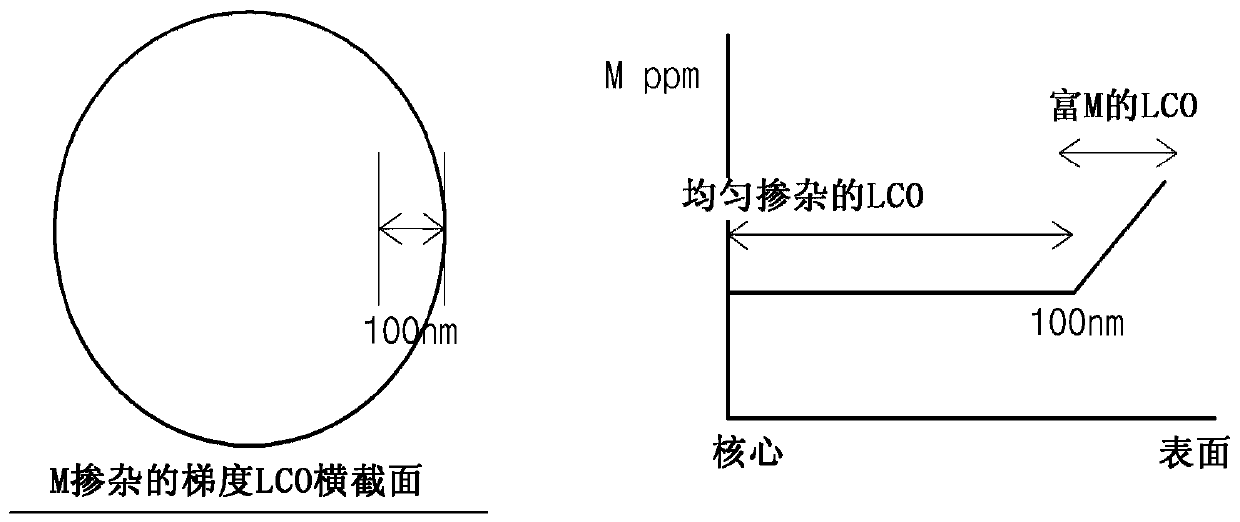

[0042]

[0043] Next, by doping Co with the doping element M in an amount of 1,000 ppm or more 3 o 4 Or the CoOOH precursor is mixed with the lithium raw material, and the first heat treatment is performed to prepare the lithium cobalt oxide.

[0044] As the lithium raw material, lithium-containing sulfate, lithium-containing nitrate, lithium-containing acetate, lithium-containing carbonate, lithium-containing oxalate, lithium-containing citrate, lithium-containing halide, lithium-containing hydroxide can be used , lithium-containing oxyhydroxide, etc., and the lithium raw material is not particularly limited as long as it can be dissolved in water. Specifically, the lithium raw material can be Li 2 CO 3 、LiNO 3 、LiNO 2 , LiOH, LiOH·H 2 O, LiH, LiF, LiCl, LiBr, LiI, CH 3 COOLi, Li 2 O. Li 2 SO 4 、CH 3 COOLi, Li 3 C 6 h 5 o 7 etc., and any one of the above materials or a mixture of two or more thereof may be used.

[0045] In addition, the amount of the lithi...

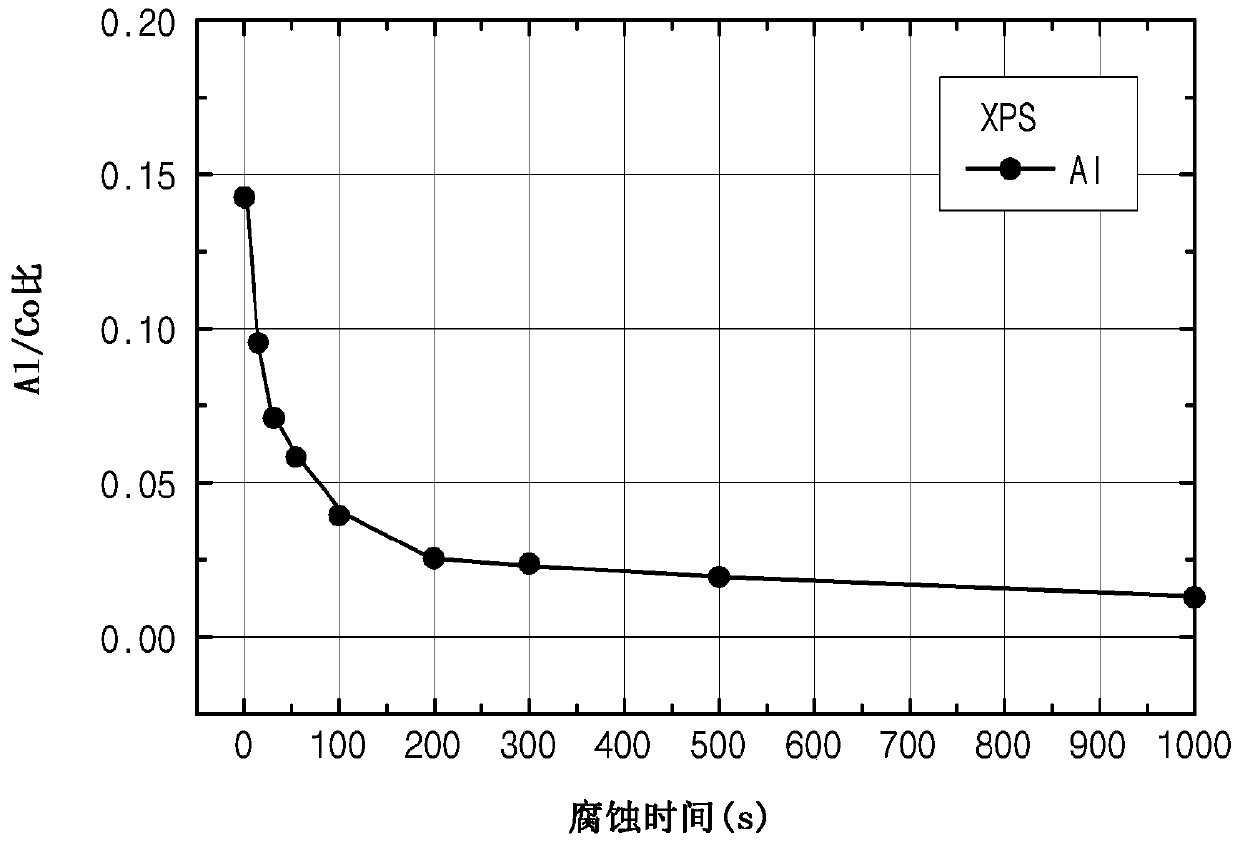

Embodiment 1

[0105] In a 5 L batch reactor set at 60 °C, the CoSO 4 mixed in water, and further compared to CoSO 4 Al mixed in an amount of 0.3% by weight 2 (SO 4 ) 3 , to prepare a precursor-forming solution at a concentration of 2M. Connect the vessel containing the precursor-forming solution to load it into the reactor, and additionally prepare 25% aqueous NaOH and 15% NH 4 OH aqueous solution and connect it to the reactor. Add 1 L of deionized water into the co-precipitation reactor (capacity of 5 L), then purge nitrogen into the reactor at a rate of 2 L / min to remove dissolved oxygen in the water, and set the interior of the reactor to non-oxidizing atmosphere. Thereafter, 10 ml of a 25% aqueous NaOH solution was added, and the mixture was stirred at a temperature of 60° C. at a stirring speed of 1,200 rpm so as to maintain a pH of 12.0. Then, the precursor forming solution was added at 4 ml / min, the NaOH aqueous solution was added at 1 ml / min, and the NH 4 OH aqueous solution...

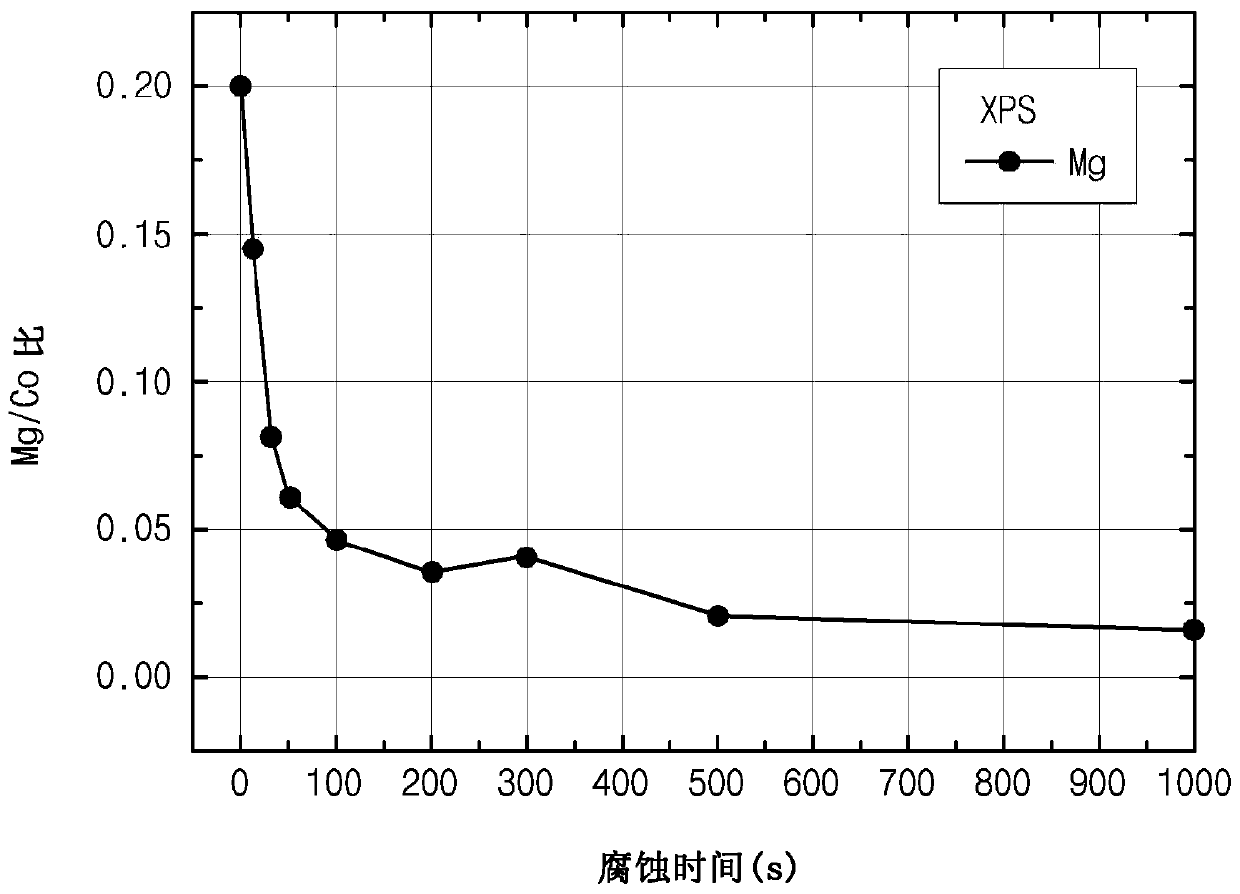

Embodiment 2

[0109] In addition to using MgSO in precursor doping 4 instead of Al 2 (SO 4 ) 3 Preparation of 4,000 ppm Mg-doped Co as doping raw material 3 o 4 Precursor, using 0.3 parts by weight of MgO instead of Al(OH) in the second heat treatment 3, and performing a second heat treatment at 850° C. for about 5 hours to prepare a positive active material whose surface is additionally doped with Mg, the positive active material was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com