Erbium-doped fiber laser of random Raman fiber laser in-band pumping

A random laser and fiber laser technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of complex 1480 nm laser generation process, complex overall structure, and high overall cost, and achieve reduced implementation difficulty and high optical Efficiency, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

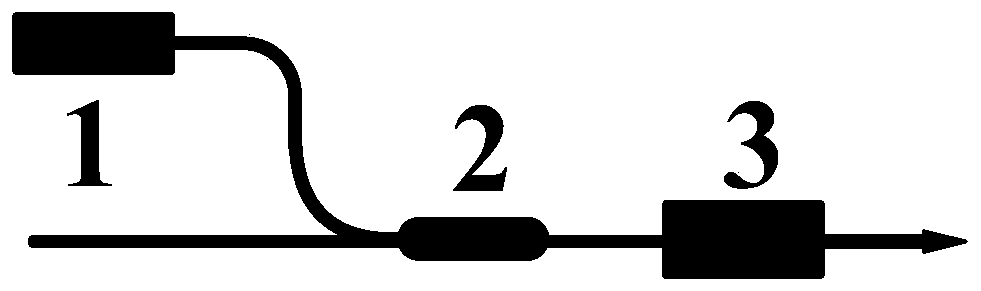

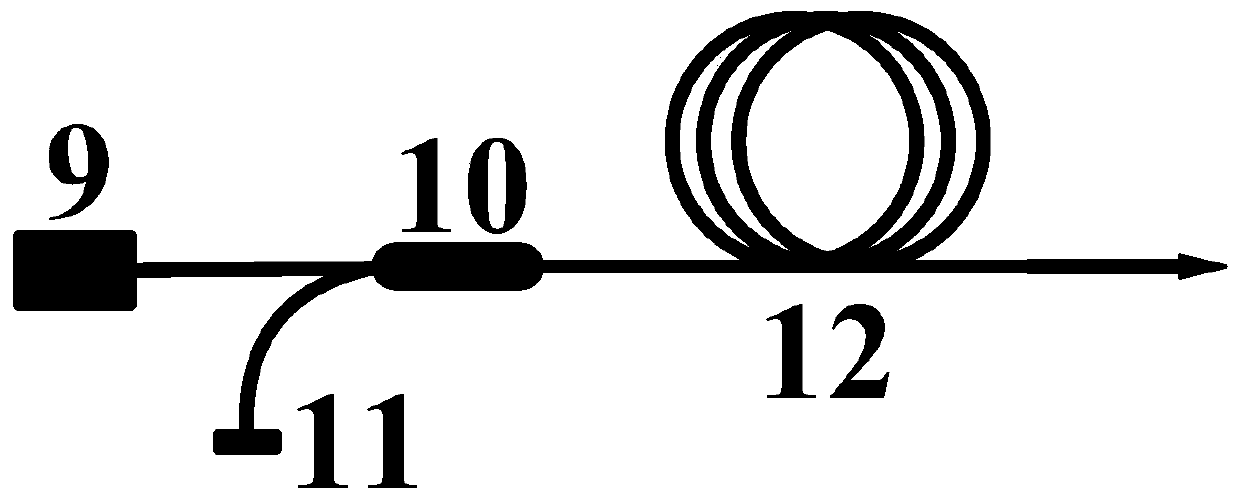

[0031] Example 1, reference Figure 4, a random 1480-nm laser-pumped high-power 1.5-micron erbium-doped fiber laser amplifier. The 1.5-micron seed laser 5 is coupled into the erbium-doped fiber 4 through the wavelength division multiplexer 2 . The initial pump wavelength of the random laser is 1064 nm, and the 6th-order Stokes laser is generated by random Raman process, which are 1117, 1175, 1239, 1310, 1390, and 1480 nm, respectively. By optimizing the Raman fiber length and 1064 Nano-laser power, and ultimately the 1480-nm laser power accounts for the major part of the total output power. The 1480-nanometer laser generated by the random laser is coupled into the erbium-doped fiber 4 through the wavelength division multiplexer 2, and 8 is a pump laser filter, which can filter out the redundant unabsorbed random laser. The low-power 1.5-micron laser can be amplified into a high-power 1.5-micron laser output at the end of the pump laser filter 8 or connected to a fiber collim...

Embodiment 2

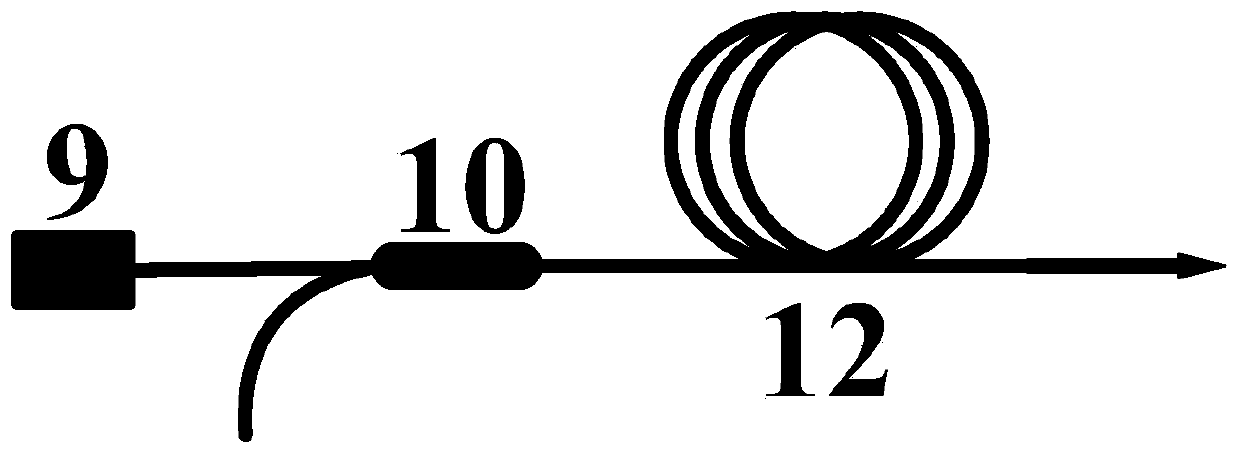

[0032] Example 2, reference Figure 5 , a random 1510-nm laser-pumped high-power 1.56-micron erbium-doped fiber resonator. The initial pump wavelength of the random laser is 1080 nm, and the 6th-order Stokes laser is generated by the random Raman process, which are 1133, 1195, 1262, 1337, 1419, and 1510 nm, respectively. By optimizing the Raman fiber length and the 1080 nm laser power, the final 1510 nm laser power accounts for the major part of the total output power. The 1510 nm laser generated by random laser is coupled into the erbium-doped fiber 4 through the wavelength division multiplexer 2. 6 and 7 are 1560 nm high reflectivity fiber Bragg grating and low reflectivity fiber Bragg grating respectively, 8 is the pump laser filter , which can filter out unwanted unabsorbed random laser light. The high-power 1.56-micron laser can be output at the end of the pump laser filter 8 or connected to a fiber collimator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com