Method for cooperatively treating volatile organic compounds and nitrogen-containing and sulfur-containing malodorous substances

A volatile organic compound and co-processing technology, applied in the field of environmental engineering, can solve the problem that sulfur-containing, nitrogen-containing and odorous substances cannot be effectively co-processed with biological treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

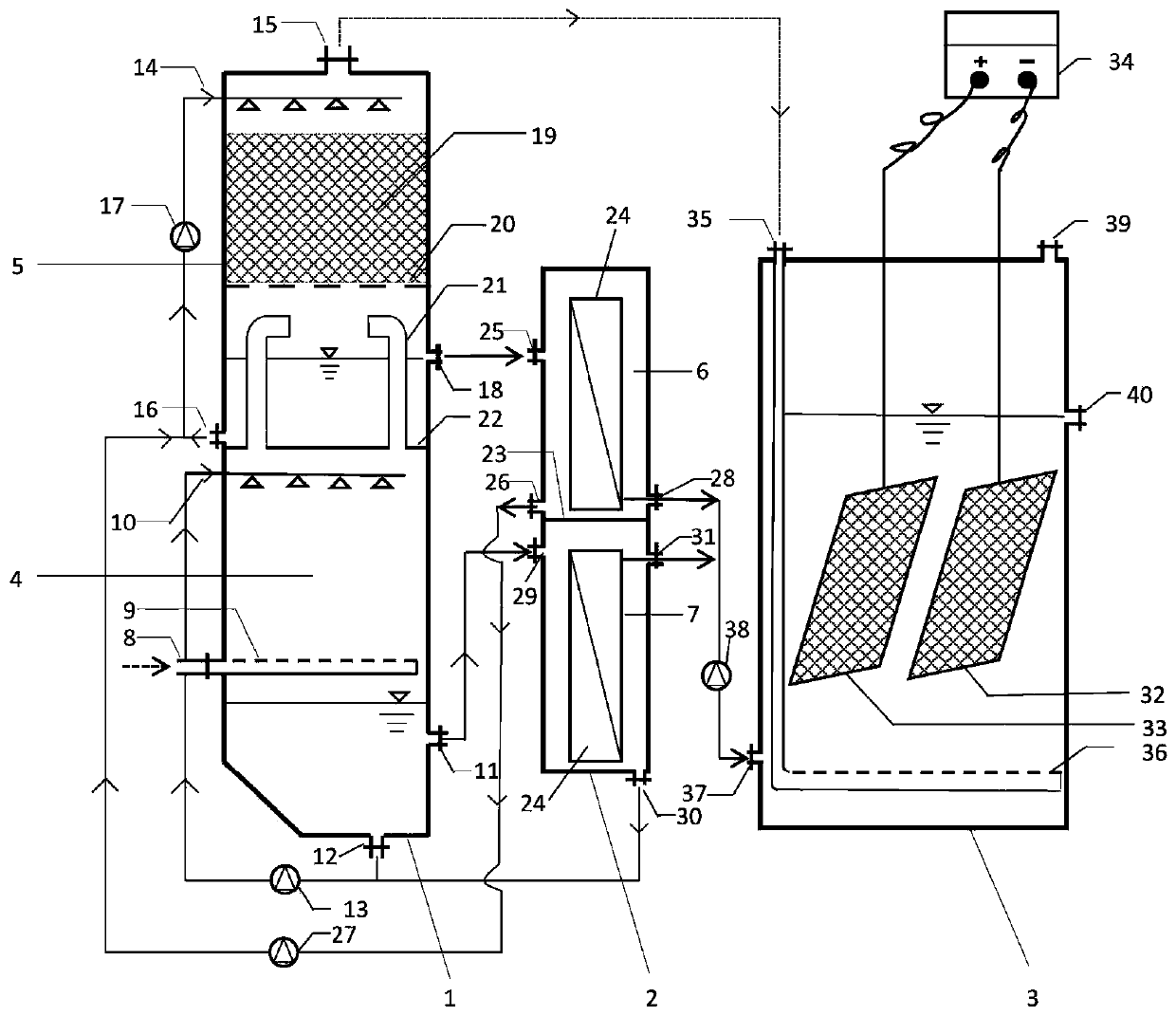

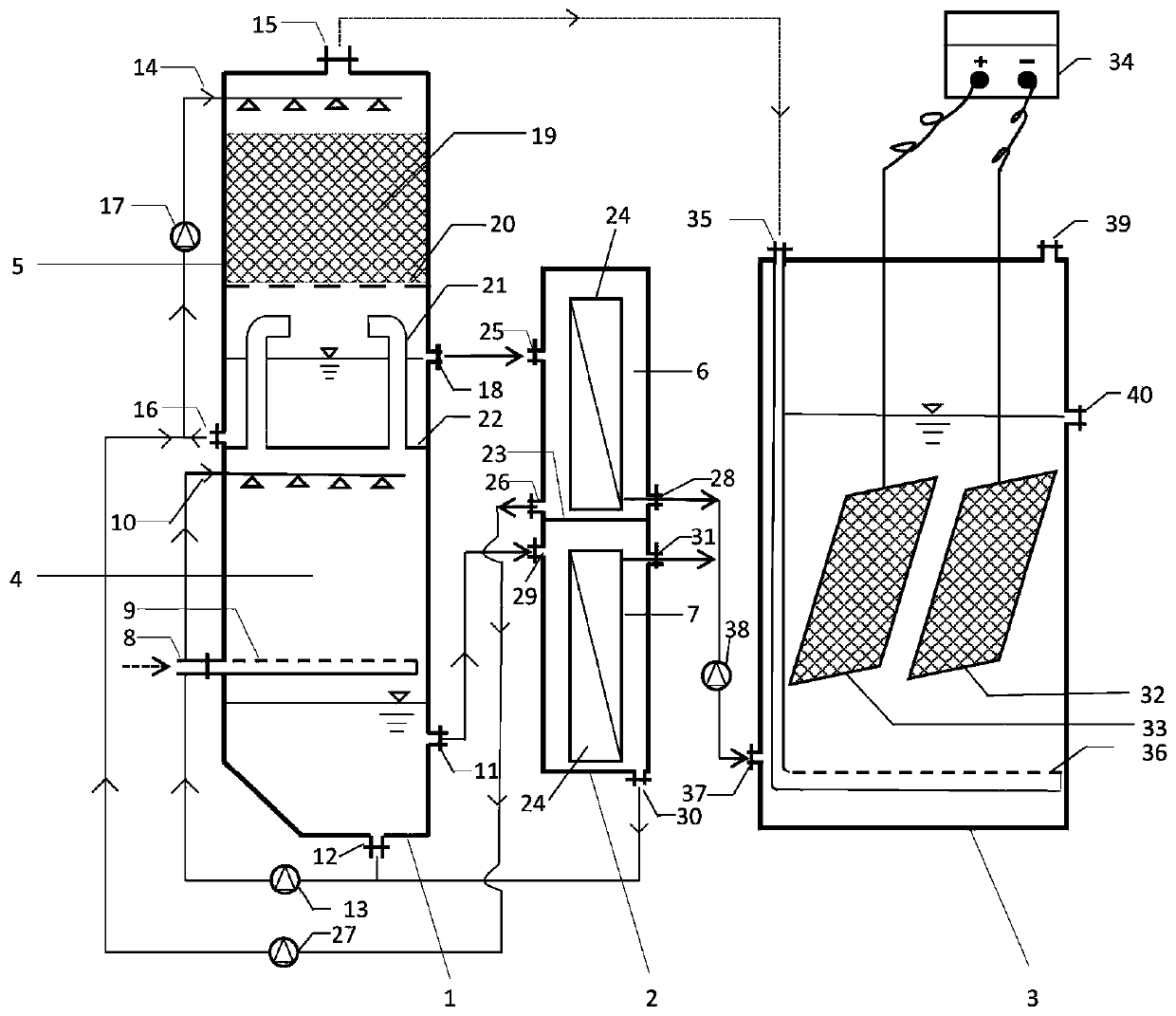

[0109] Embodiment 1 A kind of method of co-processing hydrogen sulfide, ammonia and styrene

[0110] For the processing equipment structure adopted in this embodiment, please refer to figure 1 .

[0111] The push-flow combined bio-electrochemical co-processing treatment equipment for volatile organic compounds and nitrogen-containing sulfur-containing malodorous substances made of plexiglass plastic plates has a length, width, and height of 1.0m, 0.75m, and 1.50m, respectively.

[0112] In the bio-electrochemical reaction container 3 , the electrode material of the cathode 32 and the anode 33 is stainless steel mesh, and the electrodes are parallel to the bottom plane of the bio-electrochemical reaction container 3 .

[0113] The porous partition of the plug-flow oxidation vessel has multiple holes with a diameter of 50mm; the outlet of the vent pipe in the fixed desulfurization zone is higher than the second water outlet and lower than the gas distribution plate; the gas dis...

Embodiment 2

[0139] Embodiment 2. A kind of method of co-processing hydrogen sulfide, ammonia and methane

[0140] For the processing equipment structure adopted in this embodiment, please refer to figure 1 . The plug-flow combined bio-electrochemical co-processing treatment equipment for volatile organic compounds and nitrogen-containing sulfur-containing malodorous substances made of stainless steel plate has a length, width and height of 0.8m, 0.5m and 1.2m respectively. In the bio-electrochemical reaction vessel 3, the electrode material of the cathode 32 and the anode 33 is carbon felt, the angle between the anode 33 and the electrode and the bottom plane of the bio-electrochemical reaction vessel 3 is 60 degrees, and the angle between the anode 32 and the cathode is 30 degrees.

[0141] The porous partition of the plug-flow oxidation vessel has multiple holes with a diameter of 30 mm; the outlet of the vent pipe in the fixed desulfurization zone is higher than the second water outle...

Embodiment 3

[0170] Embodiment 3. A kind of method of co-processing mercaptan, ammonia, trimethylamine and ethylbenzene

[0171] For the processing equipment structure adopted in this embodiment, please refer to figure 1 . The plug-flow combined bio-electrochemical co-processing treatment equipment for volatile organic compounds and nitrogen-containing sulfur-containing malodorous substances made of plastic plates has a length, width, and height of 5.0m, 3.0m, and 2.0m, respectively.

[0172] In the bio-electrochemical reaction container 3 , the electrode material of the cathode 32 and the anode 33 is a carbon rod, and the angle between the anode 33 and the cathode 32 is perpendicular to the bottom plane of the bio-electrochemical reaction container 3 .

[0173] The porous partition of the plug-flow oxidation vessel has multiple holes with a diameter of 80 mm; the outlet of the vent pipe in the fixed desulfurization zone is higher than the second water outlet and lower than the gas distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com