Preparation method of graphene oxide modified triptycenyl polyamide separation membrane

A technique for modification of ptycene-based polyamide and graphene, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., to achieve the effects of reducing investment costs, high uniformity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

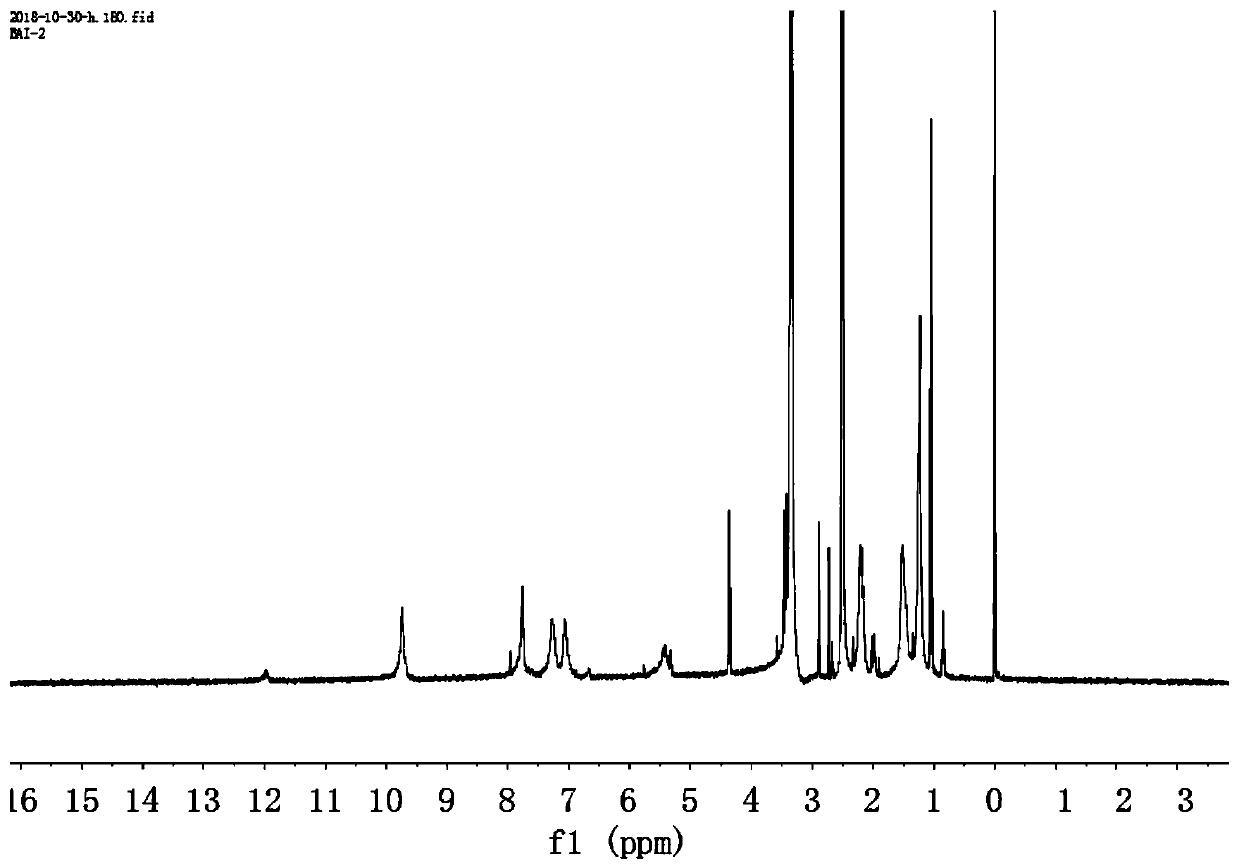

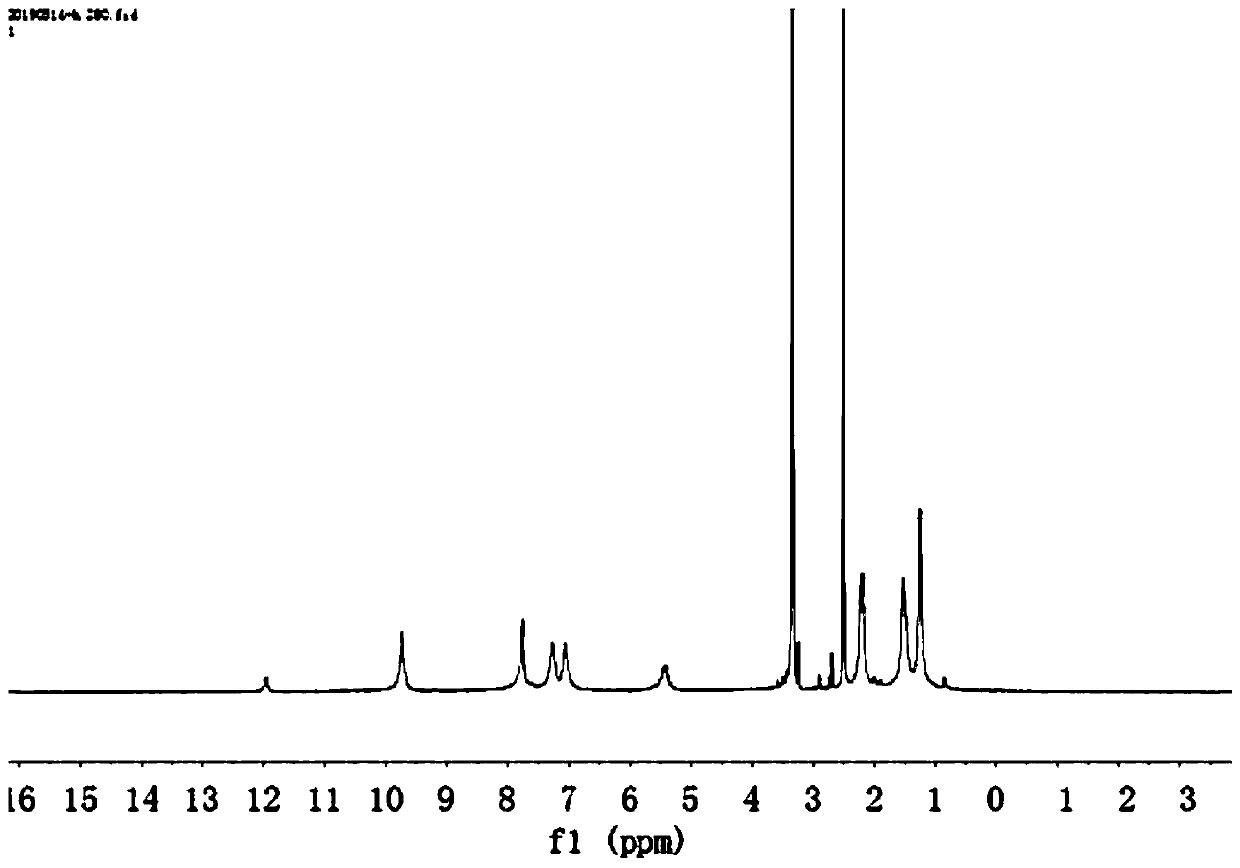

[0056] Get 0.3g (1mmol) of 2,6,14-triaminotriptycene, put it into a 250ml three-necked flask, add 20ml dimethylformamide at normal temperature to stir and dissolve, then add 0.15mg graphene oxide (purchased from Nanjing Jicang Nano Technology Co., Ltd., model: JCGO-1-2), add 10ml dimethylformamide to configure the dispersion (put 0.15mg graphene oxide and 10ml dimethylformamide in a 20ml strain bottle, Then put it in an ultrasonic device, ultrasonic for 30min), pour the prepared graphene oxide dispersion into a three-necked flask, then add 0.9g (11.4mmol) of pyridine, then lower the temperature to -5°C, and react under nitrogen Under protection, add 20ml of dimethylformamide to the round bottom flask at the same time, add suberoyl chloride 0.6g (2.84mmol) after the temperature drops to -5°C, and add 10ml of dimethylformamide at the same time. React at -5°C for 2.5 hours under nitrogen protection. After the reaction was completed, the reaction temperature was raised to room te...

Embodiment 2

[0064] Take 0.6g (2mmol) of 2,7,14-triaminotriptycene, put it into a 250ml three-necked flask, add 20ml of methylpyrrolidone at room temperature for stirring and dissolving, and then add 0.6mg of graphene oxide to 10ml of methylpyrrolidone Carry out the configuration of the dispersion (put 0.6mg graphene oxide and 10ml methylpyrrolidone in a 20ml inoculum bottle, then place it in an ultrasonic device, and ultrasonicate for 30min), pour the configured graphene oxide dispersion into a three-necked flask , then add 3g (29.65mmol) of triethylamine, and then lower the temperature to 0°C, and the reaction is carried out under the protection of nitrogen, and at the same time, add 20ml of methylpyrrolidone to the round-bottomed flask, and add after the temperature drops to 0°C Add 1.8 g (9.84 mmol) of adipoyl chloride, and add 10 ml of methylpyrrolidone at the same time, and react for 3 hours at a temperature of 0° C. under nitrogen protection. After the reaction was completed, the re...

Embodiment 3

[0072] Take 0.45g (1.38mmol) of 9,10-dimethyl-2,6,14-triaminotriptycene, put it into a 250ml three-necked flask, add 20ml of dimethylformamide at room temperature to stir and dissolve, and then put 0.675mg graphene oxide, add 10ml dimethylformamide to prepare the dispersion (put 0.675mg graphene oxide and 10ml dimethylformamide in a 20ml strain bottle, then place it in an ultrasonic device, and ultrasonicate for 30min) , Pour the prepared graphene oxide dispersion into a three-necked flask, then add 1.8g (22.76mmol) of pyridine, and then lower the temperature to 5°C, and the reaction is carried out under the protection of nitrogen, and at the same time, add to the round bottom flask Add 20ml of dimethylformamide, and after the temperature drops to 5°C, add 0.9g (4.57mmol) of pimeloyl chloride, and at the same time add 10ml of dimethylformamide, and react at a temperature of 5°C under nitrogen protection for 4 hours. After the reaction was completed, the reaction temperature wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com