Olefin/alkane separation membrane and preparation method thereof

A technology for separating membranes and alkanes, applied in the field of composite materials, can solve the problems of membrane liquid loss, poor liquid membrane stability, decreased permeability, etc., to achieve high gas permeation rate, mild separation conditions, and improve the effect of permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The olefin / alkane separation membrane 1 was prepared by the following steps:

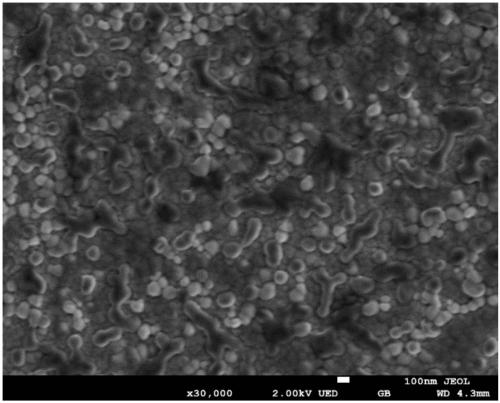

[0042] Step (1), the polyimide porous base film surface that is distributed with the hole diameter of 100nm is coated with polydimethylsiloxane solution on the surface, and after it is air-dried, a supporting film layer with a thickness of 1 μm is obtained;

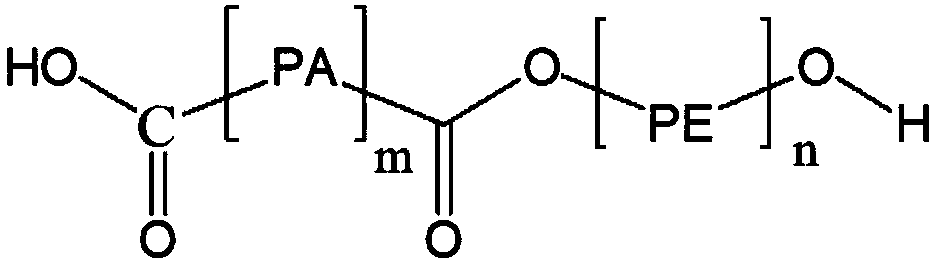

[0043] Step (2), silver nitrate and N,N-dimethylbenzamide (DMBA) are dissolved in water at a molar ratio of 1:2, and stirred until a uniform silver complex Ag(DMBA) is obtained 2 + After the solution, press it as Ag(DMBA) 2 + :LiTf 2 N=1:1 molar ratio and ionic liquid LiTf 2 N mixed, formulated as a silver ion complex Ag(DMBA) 2 + As a cation, with Tf 2 N - It is the solution of the ionic liquid of anion, this ionic liquid and polyether-polyamide block copolymer (brand is Pebax1657, wherein the number average molecular weight of nylon-6 component is 300~5000, and content is 40wt%, polyepoxide The number-average molecular weight ...

Embodiment 2

[0047] The olefin / alkane separation membrane 2 is prepared by the following steps:

[0048] The difference with Example 1 is only that the weight ratio of ionic liquid and polyether-polyamide block copolymer in step (2) is 4:1;

[0049] In Example 2, the olefin / alkane separation membrane 2 was obtained.

Embodiment 3

[0051] The olefin / alkane separation membrane 3 is prepared by the following steps:

[0052] The difference with Example 1 is only that the weight ratio of ionic liquid and polyether-polyamide block copolymer in step (2) is 0.2:1;

[0053] In Example 3, the olefin / alkane separation membrane 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com