A single-atom Pt-supported tungsten oxide single-layer nanosheet catalyst with ultra-high catalytic activity and its preparation method and application

A tungsten oxide single-layer, catalytically active technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low utilization rate of Pt-based catalysts and low yield Advanced problems, to achieve the effect of stable catalyst structure, high yield and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

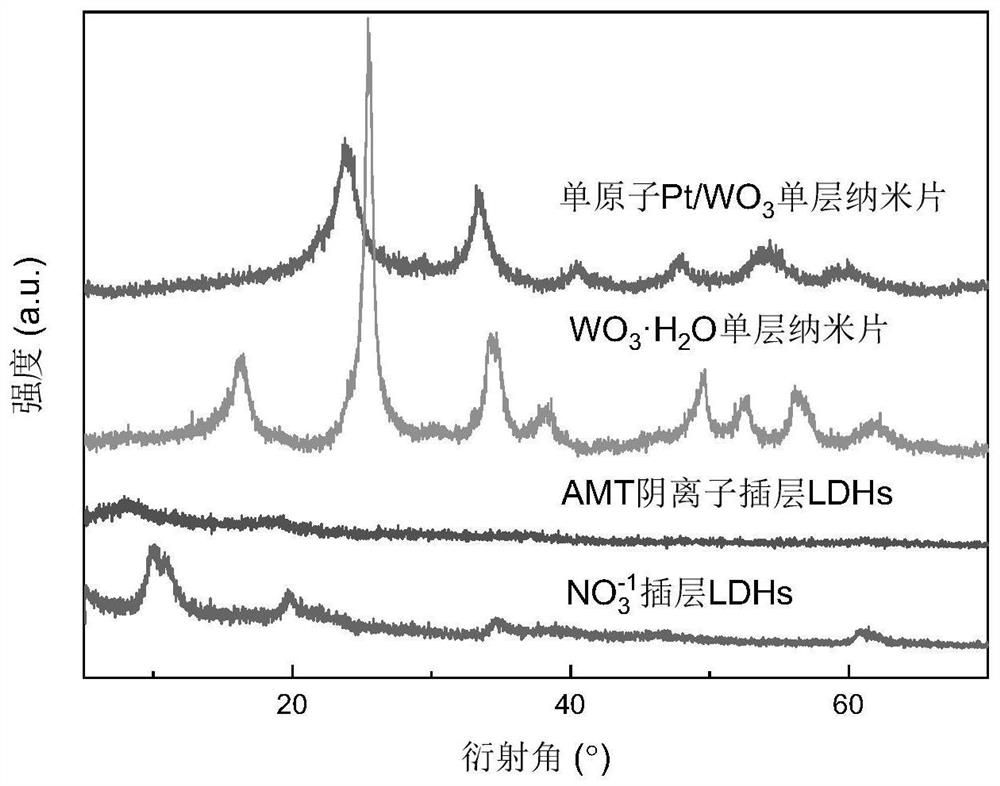

[0053] A method for preparing a single-atom Pt-supported tungsten oxide single-layer nanosheet catalyst with ultrahigh catalytic activity, comprising the steps of:

[0054] Preparation of metatungstate anion intercalation LDHs complex by ion exchange method:

[0055] Take 10.2g Mg(NO 3 ) 2 ·6H 2 O and 7.6g Al(NO 3 ) 3 9H 2 O was dissolved in 200ml deionized water to obtain solution A. Take 6.4g NaOH and dissolve in 100ml deionized water to obtain solution B. Solutions A and B were simultaneously added dropwise to 50 ml of degassed deionized water C under stirring conditions, and the pH was controlled to be 10.0 under nitrogen protection. After stirring at room temperature for 30 min, it was aged in an oven at 80° C. under nitrogen protection for 12 h. After filtration, washing, and vacuum drying at 60°C for 12 hours, NO 3 - Intercalated LDHs. Weigh 5.0g of prepared LDHs and 5.0g of ammonium metatungstate into 100ml of degassed deionized water, N 2 Under protection,...

Embodiment 2

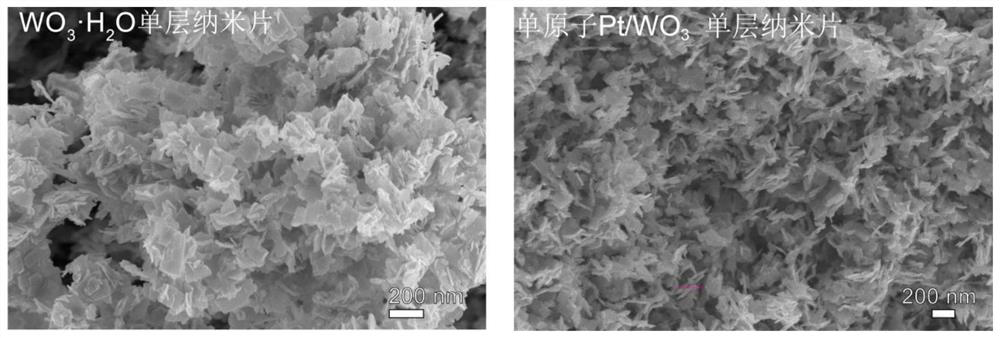

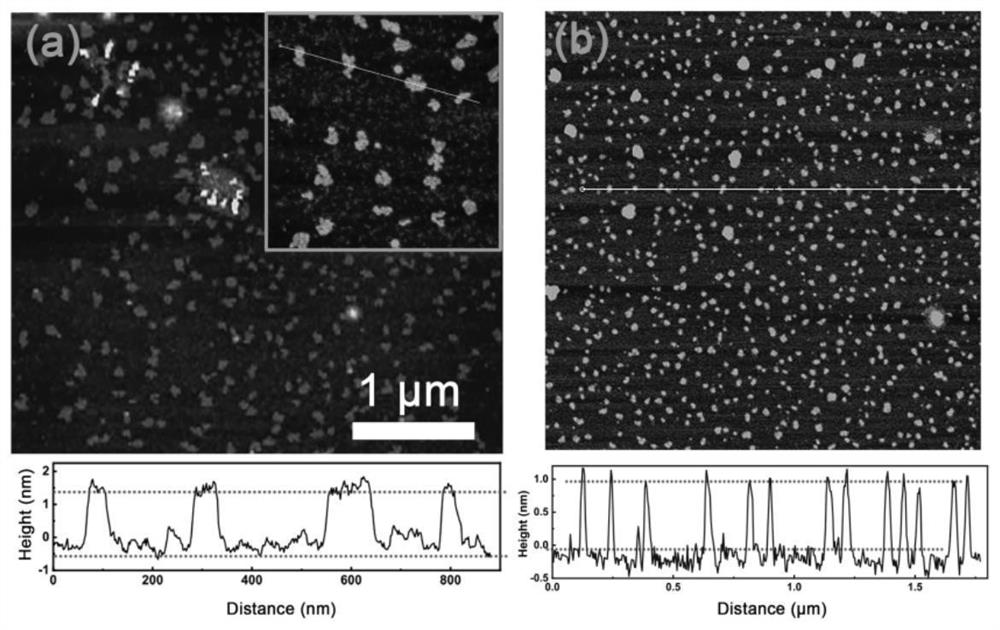

[0065] A method for preparing a single-atom Pt-supported tungsten oxide single-layer nanosheet catalyst with ultrahigh catalytic activity, as described in Example 1, the difference is: 2g WO 3 ·H 2 O single-layer nanosheets are fully dispersed in 100ml of pure water, under stirring conditions, after adding 20ml (concentration is 2g / L) aqueous solution of chloroplatinic acid dropwise, continue to stir for 10h, then obtain chloroplatinic acid through filtration, washing and freeze-drying Adsorbed WO 3 ·H 2 O monolayer nanosheets; the obtained nanosheets were placed in a tube furnace under Ar / H 2 Under atmosphere, calcined at 400°C for 1h, the heating rate was 2°C / min, and after natural cooling, a single-atom Pt-supported tungsten oxide single-layer nanosheet catalyst was obtained, that is, single-atom Pt / WO 3 Single-layer nanosheets (referred to as single-atom Pt / WO 3 -400°C monolayer nanosheets). Other steps and conditions are consistent with Example 1.

[0066] The loadi...

Embodiment 3

[0068] A method for preparing a single-atom Pt-supported tungsten oxide single-layer nanosheet catalyst with ultrahigh catalytic activity, as described in Example 1, the difference is: 2g WO 3 ·H 2 O single-layer nanosheets are fully dispersed in 100ml of pure water, under stirring conditions, after adding 20ml (concentration is 2g / L) aqueous solution of chloroplatinic acid dropwise, continue to stir for 10h, then obtain chloroplatinic acid through filtration, washing and freeze-drying Adsorbed WO 3 ·H 2 O monolayer nanosheets; the obtained nanosheets were placed in a tube furnace under Ar / H 2 Under atmosphere, calcined at 500°C for 1h, the heating rate was 2°C / min, and after natural cooling, a single-atom Pt-supported tungsten oxide single-layer nanosheet catalyst was obtained, that is, single-atom Pt / WO 3 Single-layer nanosheets (referred to as single-atom Pt / WO 3 -500°C monolayer nanosheets). Other steps and conditions are consistent with Example 1.

[0069] The loadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com