Preparation and application of boron-doped carbon shell coated CoNi nanoparticle composite material

A nanoparticle and composite material technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor catalytic activity and catalyst corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

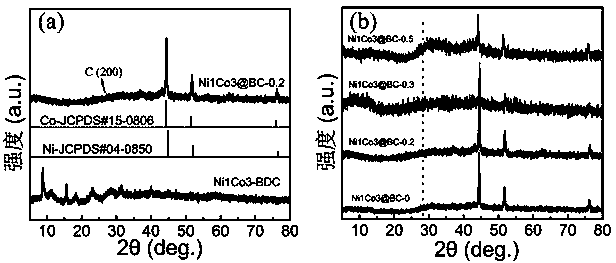

Embodiment 1

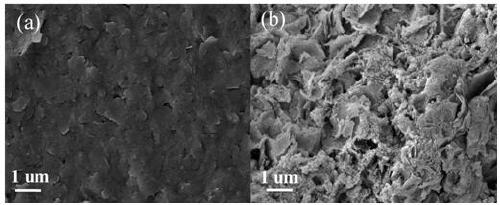

[0031] (1) Dissolve 1.5 mmol BDC in a mixed solution of 64 mL DMF, 4 mL ethanol and 4 mL deionized water at room temperature. After ultrasonication for 0.5h and magnetic stirring for 0.3h, 90mg NiCl 2 •6H 2 O and 270 mg CoCl 2 •6H 2 O was added to the above mixed solution, then 2 mL of TEA was quickly injected, the solution was magnetically stirred for 10 min to form a homogeneous suspension, and it was further continuously ultrasonicated for 8 h under sealed conditions, and finally washed alternately with DMF and ethanol for 3 times and collected by centrifugation. Vacuum drying at ℃ to obtain Ni1Co3-BDC;

[0032] (2) 0.6g Ni1Co3-BDC and 0.2g H 3 BO 3 Mixed and annealed directly in an Ar atmosphere, kept at 400 °C for 2 h, then raised to 600 °C for 1 h, to prepare Ni1Co3@BC-0.2;

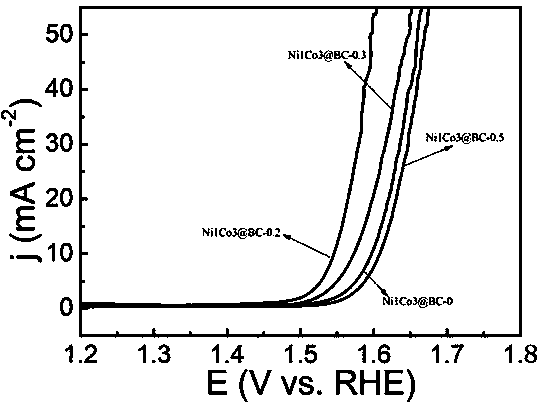

[0033] (3) Electrochemical performance test of Ni1Co3@BC-0.2: at a current density of 10mA / cm2 , the overpotential of Ni1Co3@BC-0.2 is 314mV, Tafel is 62mV dec -1 .

Embodiment 2

[0035] (1) Same as embodiment 1;

[0036] (2) 0.6g Ni1Co3-BDC and 0.3g H 3 BO 3 Mixed and annealed directly in Ar atmosphere, kept at 400°C for 2 h, and then raised to 600°C for 1 h to prepare Ni1Co3@BC-0.3;

[0037] (3) Electrochemical performance test of Ni1Co3@BC-0.3: at a current density of 10mA / cm 2 , the overpotential of Ni1Co3@BC-0.2 is 335mV, Tafel is 71mV dec -1 .

Embodiment 3

[0039] (1) Same as embodiment 1;

[0040] (2) 0.6g Ni1Co3-BDC and 0.5g H 3 BO 3 Mixed and annealed directly in an Ar atmosphere, kept at 400°C for 2 h, and then raised to 600°C for 1 h to prepare the electrocatalyst Ni1Co3@BC-0.5;

[0041] (3) Electrochemical performance test of Ni1Co3@BC-0.5: at a current density of 10mA / cm 2 , the overpotential of Ni1Co3@BC-0.2 is 380mV, Tafel is 91mV dec -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com