Ion exchange device and application thereof in preparation of hydroxylamine nitrate or hydroxylamine perchlorate

An ion exchange device and ion exchange technology, applied in the direction of ion exchange column/bed method, hydroxylamine, non-metallic elements, etc., can solve the problems of large consumption of raw materials, low production capacity, high cost, etc., to avoid empty towers or overflow towers, The effect of reducing material residue and reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

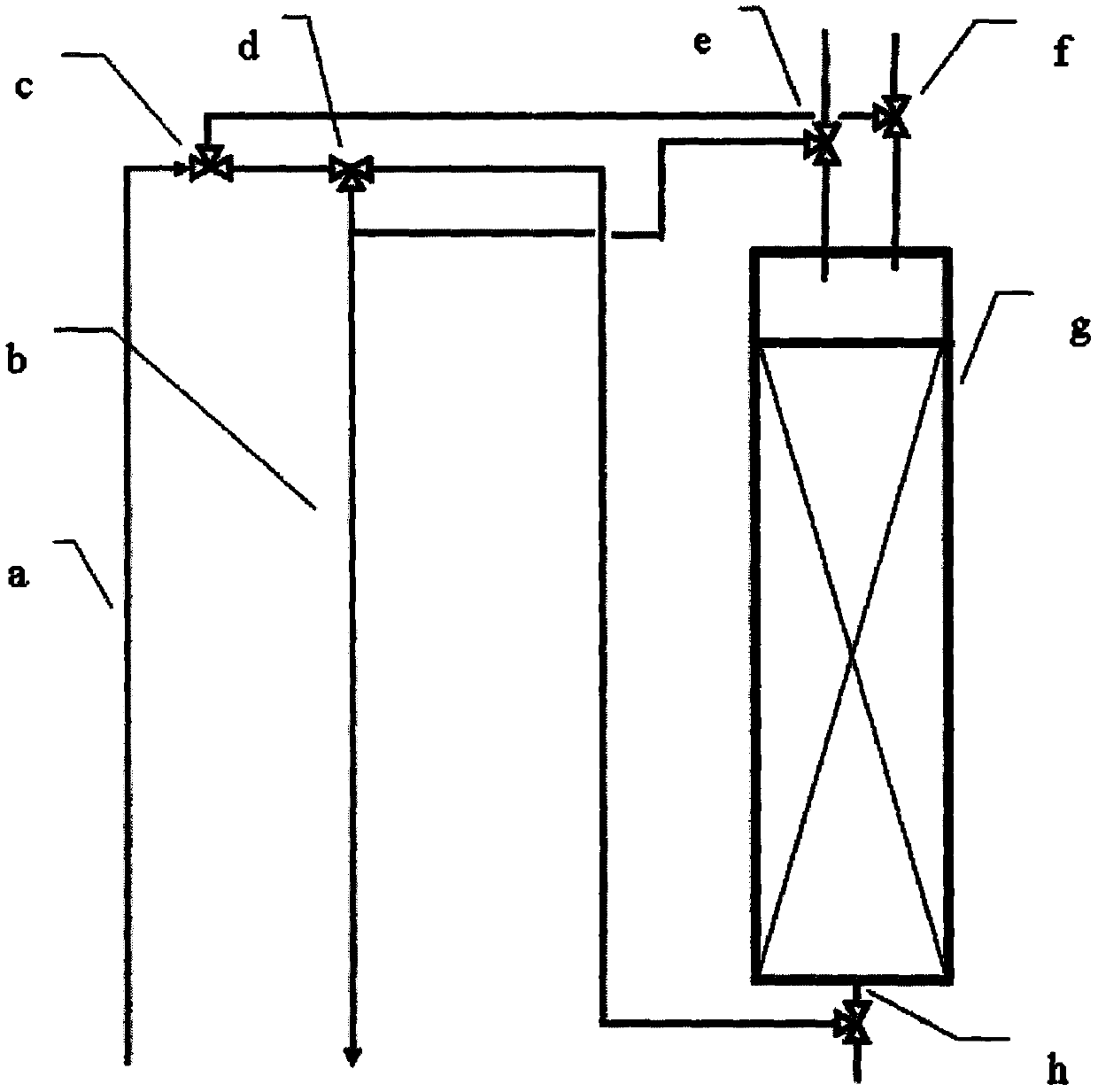

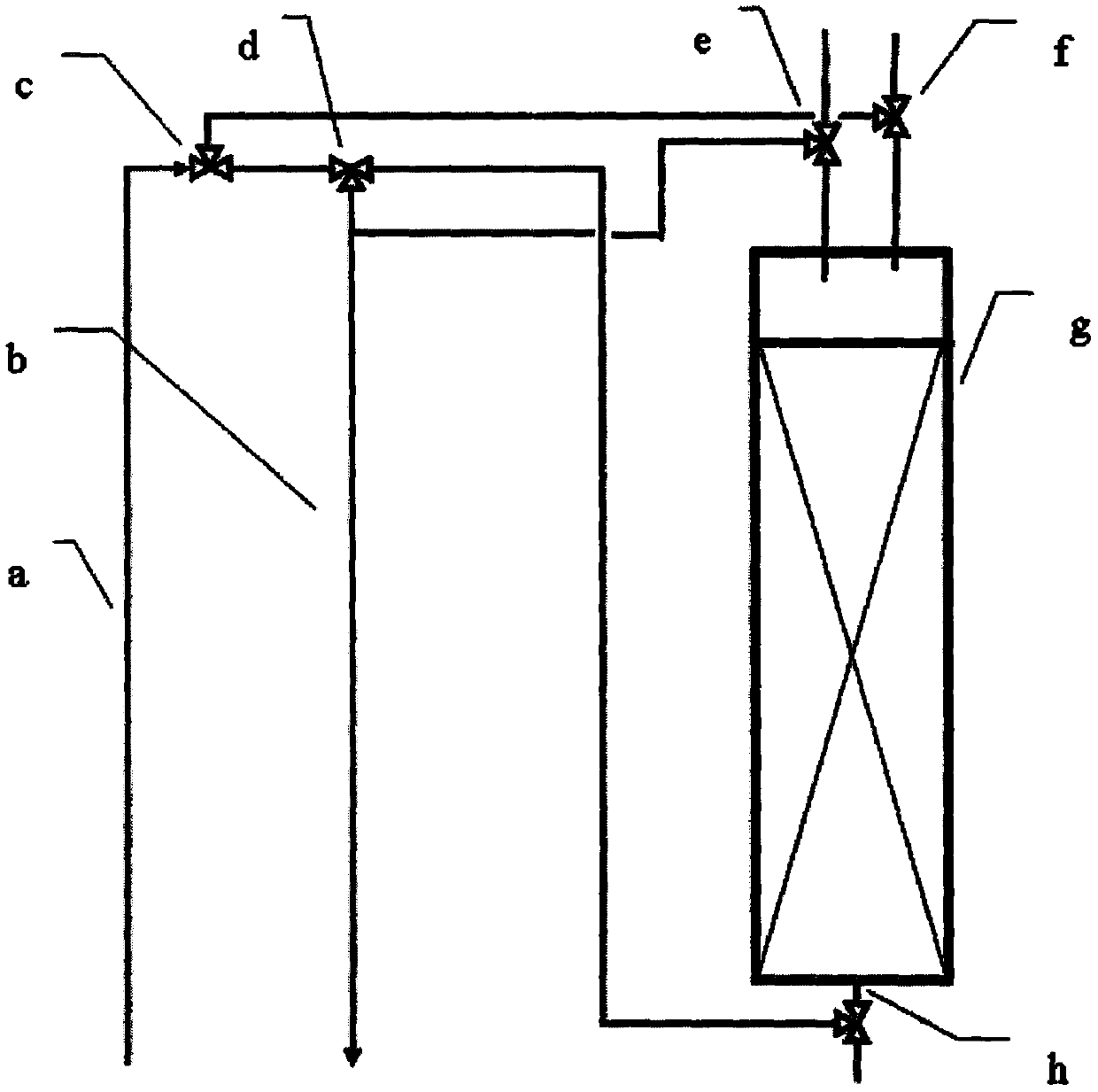

[0024] Switch the valve, add 682mL of 10% hydroxylamine sulfate aqueous solution to the Φ3.5×40cm (resin loading capacity: 370mL) ion exchange column from bottom to top at a flow rate of 11-12mL / min, and absorb the residual liquid from the ion exchange column through the IV three-way valve e. The top of the exchange column flows out; after the adsorption is completed, add pure water to the ion exchange column for washing according to the above method, until no sulfate ions are detected in the washing liquid; switch the valve again, adjust the flow rate to 5-6mL / min, from top to bottom Add 152mL nitric acid aqueous solution down to the ion exchange column, the eluent flows out from the bottom of the column through the third three-way valve h, passes upward through the fourth three-way valve e, and is discharged and collected in the discharge pipe b, and the pH value of the eluent is detected , it is advisable that the pH value of the eluent is not lower than 3.0; finally wash wi...

Embodiment 2

[0026] Add 322mL of 10% aqueous solution of hydroxylamine sulfate to the Φ3.5×40cm ion exchange column, and the others are the same as in Example 1. Detect the eluent and washing solution with a pH value greater than 3.0, which contains 22.8g of hydroxylamine nitrate, the resin utilization efficiency is 49.2%, and the consumption of raw material hydroxylamine sulfate is reduced by 52.7%.

Embodiment 3

[0028] Add 276mL of 10% aqueous solution of hydroxylamine hydrochloride to the Φ3.5×40cm ion exchange column, and the others are the same as in Example 1. The eluate and washing solution with a pH value greater than 3.0 were detected, which contained 22.9g of hydroxylamine nitrate, and the resin utilization efficiency was 49.3%. The amount of raw material hydroxylamine hydrochloride is reduced by 52.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com