Ceramic/polytetrafluoroethylene composite dielectric substrate and preparation method thereof

A polytetrafluoroethylene and ceramic technology, applied in the field of composite dielectric substrates, can solve the problems of high requirements on dispersibility, stability and rheology, unsuitable for casting process, and inability to flow, etc., and achieves a wide range of viscosity adjustment and uniformity. Good performance and high filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

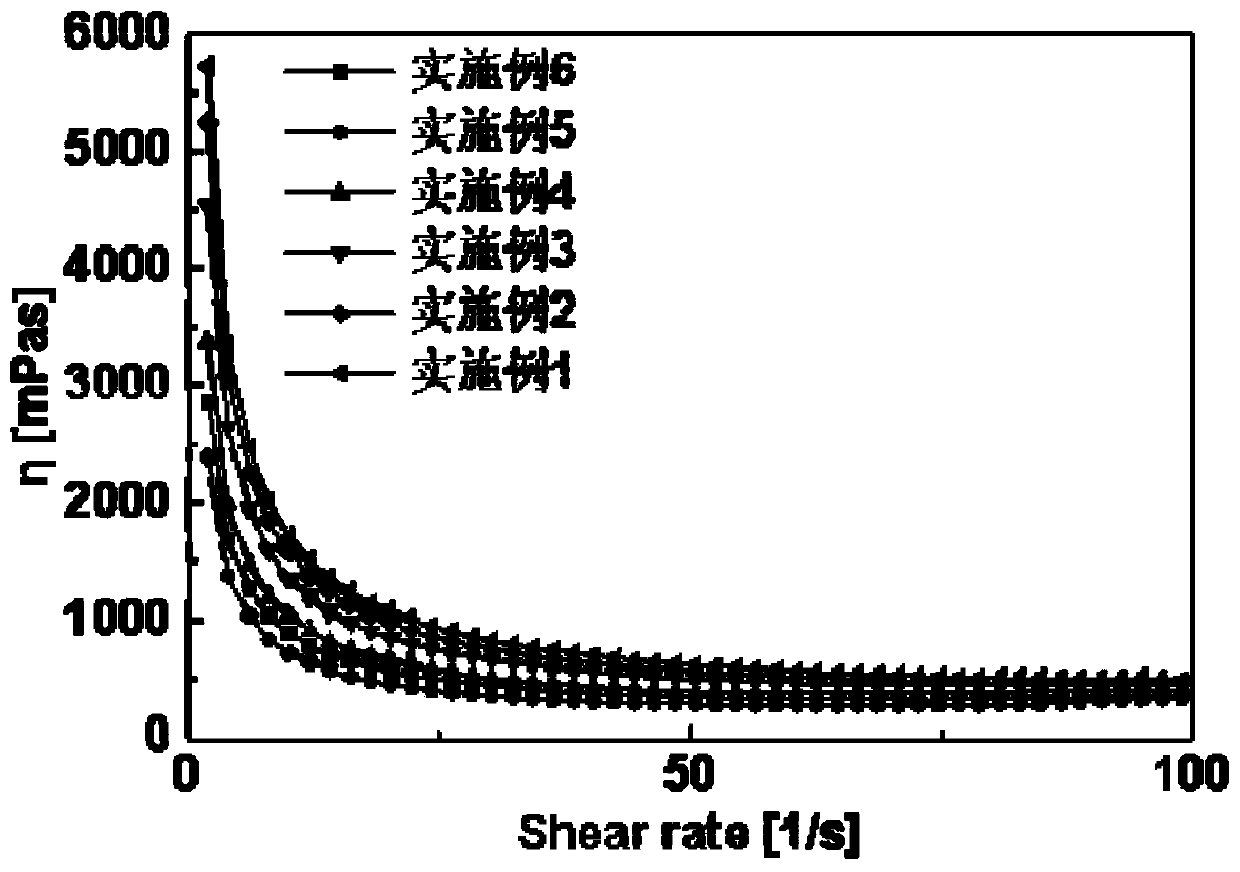

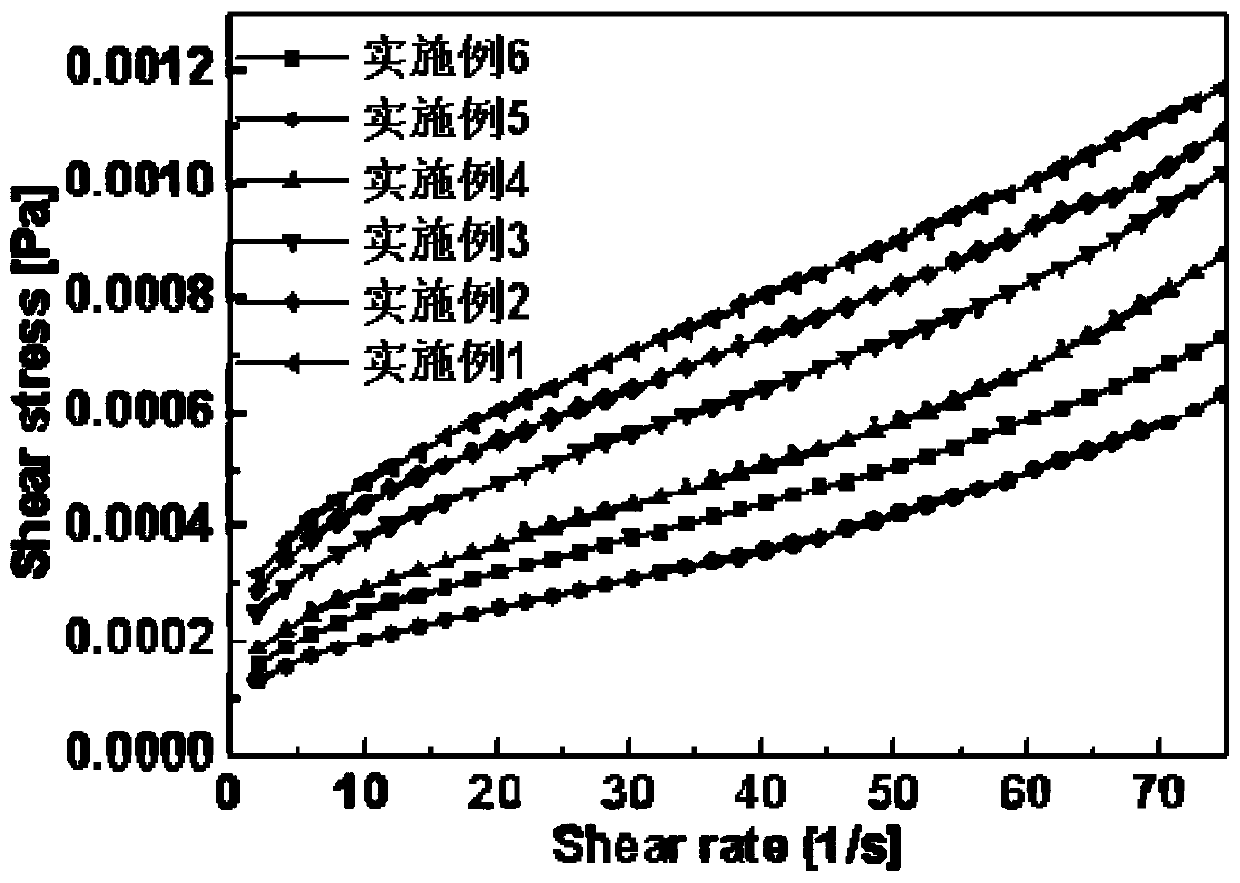

Embodiment 1

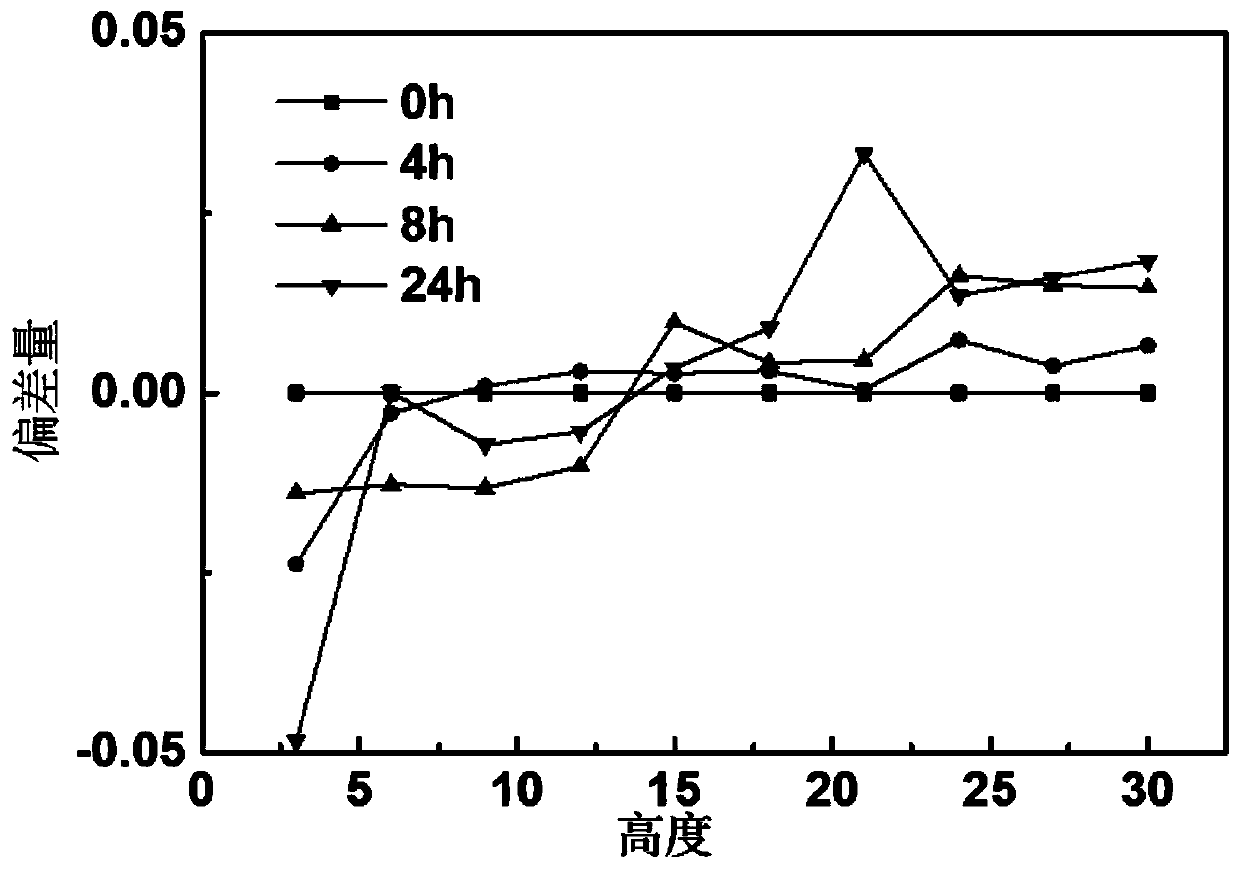

[0041] The silica powder and 60wt% polytetrafluoroethylene emulsion (brand name SFN-2H) were uniformly mixed at a ratio of 35:101.7 parts by weight. Then 4 parts by weight of the additive polyvinyl alcohol are added to adjust the slurry viscosity to the range of 500mPa·s-1500mPa·s. Adjust the height of the scraper to 2mm, cast the slurry on a 0.04mm thick glass fiber cloth substrate at a speed of 15cm / min, put it in an oven for drying, and use a gradient temperature program to discharge additives and other impurities in the cast sheet. Then cool at room temperature. The specific gradient heating program is: 80°C for 2h, 180°C for 2h, 260°C for 4h, and 330°C for 4h. Cut the cooled sheet and use a hot press to perform double-sided copper-clad hot pressing in a vacuum, high temperature and high pressure environment, where the pressure is 18MPa, the holding time is 1h, and the thickness of the copper foil is 35μm to obtain a ceramic with a thickness of 1mm. / PTFE composite dielec...

Embodiment 2

[0043] The ceramic / polytetrafluoroethylene composite dielectric substrate was prepared according to the method of Example 1, except that the weight ratio of silica powder, polytetrafluoroethylene emulsion and polyvinyl alcohol was 30:110:4.

Embodiment 3

[0045] The ceramic / polytetrafluoroethylene composite dielectric substrate was prepared according to the method of Example 1, except that the weight ratio of silica powder, polytetrafluoroethylene emulsion and polyvinyl alcohol was 25:118.3:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com