Method for preparing semaglutide by liquid phase method on basis of soluble carrier

A soluble, liquid-phase method, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of excessive waste of reactants, large consumption of raw materials, and difficulty in completeness, reducing the difficulty of purification and saving time. cost, the effect of reducing the generation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

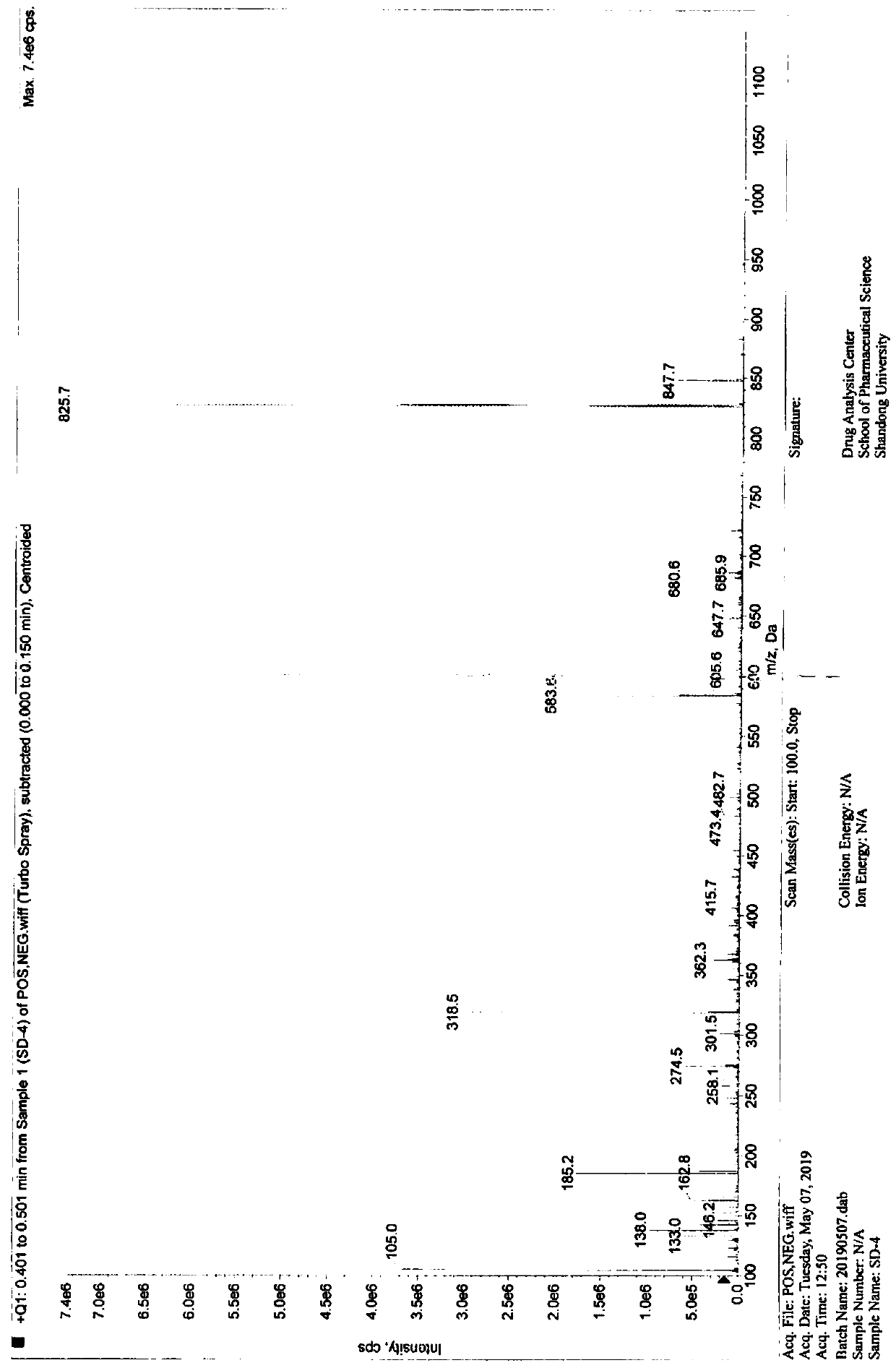

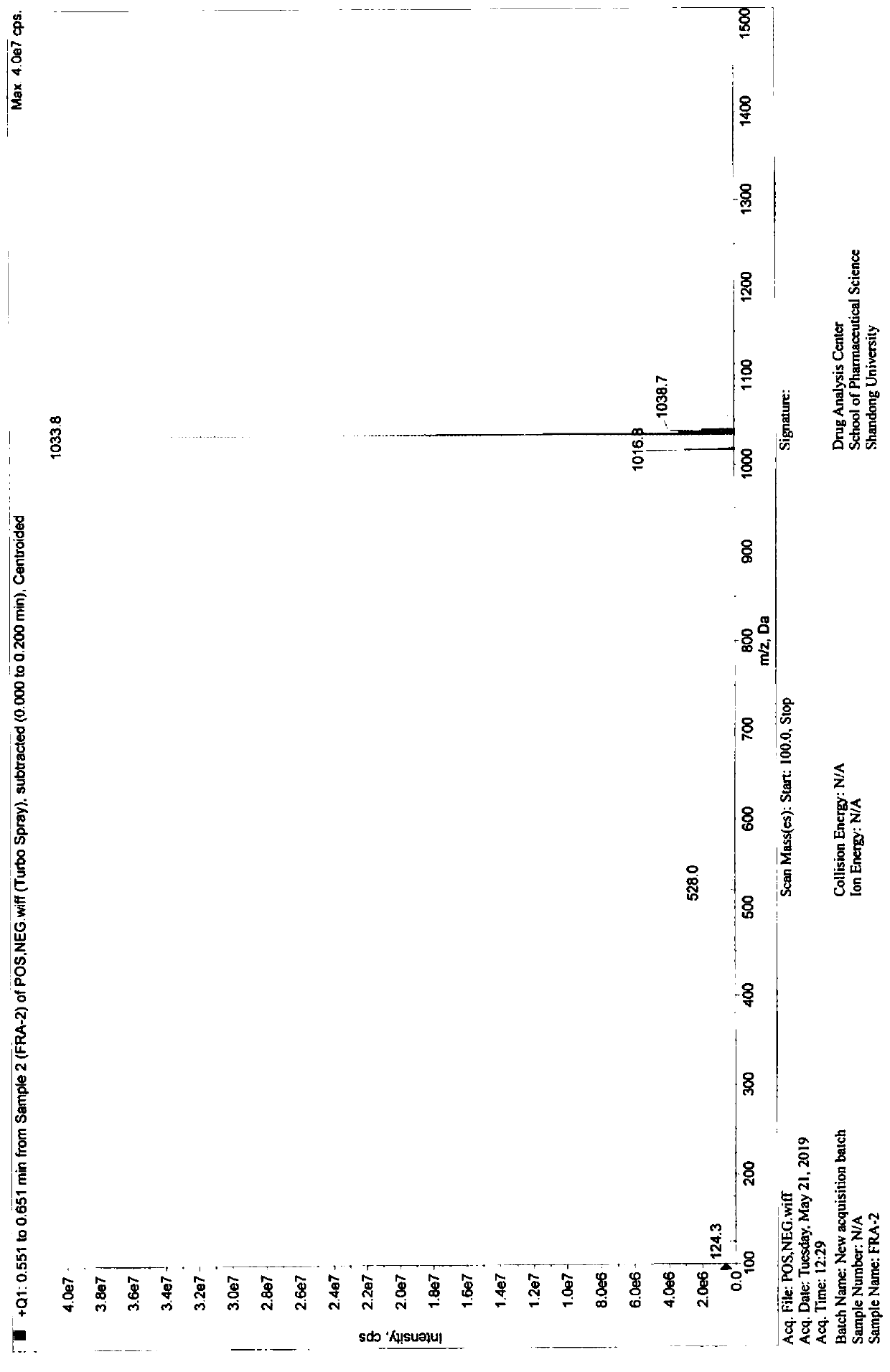

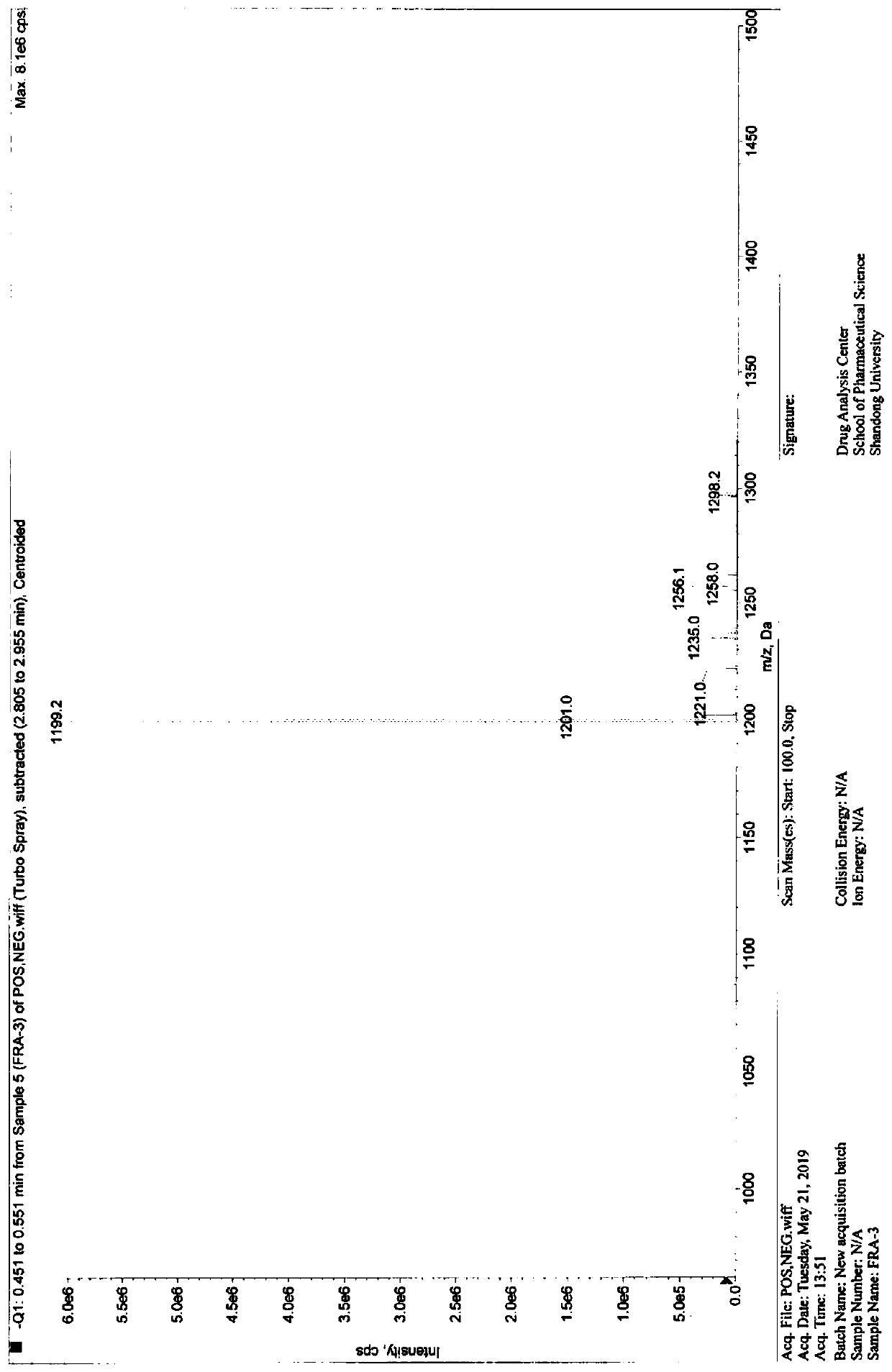

Image

Examples

Embodiment 1

[0104] Preparation of 2,4-bis(behenyloxy)benzyl alcohol (tag carrier):

[0105] 1) Preparation of intermediate 2,4-bis(behenyloxy)benzaldehyde: Weigh 2,4-dihydroxybenzaldehyde (0.6g, 4.34mmol), potassium carbonate (6.0g, 43.4mmol), 1-Bromodocosane (3.5g, 9mmol) was added into DMF (30ml), and stirred overnight at 70°C under nitrogen protection. After the reaction was completed, the reaction solution was poured into water (400ml) and stirred, filtered, and the filter cake was collected and dried to obtain 2,4-bis(behenyloxy)benzaldehyde (3.20g, yield 97.5%) .

[0106] 2) Preparation of tag carrier: Weigh the above-mentioned 2,4-bis(behenyloxy)benzaldehyde (3.0g, 3.97mmol) and dissolve it in a mixed solution of THF (60ml) and MeOH (6ml), and add to the solution Sodium borohydride (400mg, 10.57mmol) was added to it, and the reaction was stirred at 40°C for 2 hours under the protection of nitrogen. Add purified water (2-3ml) dropwise to the reaction solution until a brown-red so...

Embodiment 2

[0109] Preparation of Fully Protected Fragment 1:

[0110] 1) Preparation of Fmoc-Gly-O-tag: Weigh the tag carrier (2.27g, 3mmol) and dissolve it in DCM (60ml), add Fmoc-Gly-OH (1.34g, 4.5mmol), DIC (567mg , 4.5mmol), DMAP (73mg, 0.6mmol), stirred at room temperature for 30min, and monitored the end point of the reaction by TLC. A large amount of acetonitrile was added to the solution to precipitate crystals, and the crystals were collected by filtration to obtain the product Fmoc-Gly-O-tag (3.07 g, yield 98.8%).

[0111]2) Preparation of H-Gly-O-tag: Dissolve the above Fmoc-Gly-O-tag in THF (60ml) containing 1% DBU, add PIP (384mg, 3.6mmol) to the solution, and stir at room temperature for 5min , TLC method to monitor the reaction end point. A large amount of acetonitrile was added to the reaction solution to precipitate crystals, and the crystals were collected by filtration to obtain the product H-Gly-O-tag (2.40 g). The total yield of 1) and 2) was 98.3%.

[0112] 3) A ...

Embodiment 3

[0117] Preparation of fully protected fragment 2:

[0118] 1) Preparation of Fmoc-Asp(OtBu)-O-tag: Weigh the tag carrier (2.27g, 3mmol) and dissolve it in DCM (60ml), add Fmoc-Asp(OtBu)-OH (1.86g, 4.5 mmol), DIC (567 mg, 4.5 mmol), DMAP (73 mg, 0.6 mmol), stirred at room temperature for 30 min, and monitored the end point of the reaction by TLC. A large amount of acetonitrile was added to the solution to precipitate crystals, and the crystals were collected by filtration to obtain the product Fmoc-Asp(OtBu)-O-tag (3.40 g, yield 98.5%).

[0119] 2) Preparation of H-Asp(OtBu)-O-tag: Dissolve the above Fmoc-Asp(OtBu)-O-tag in THF (60ml) containing 1% DBU, add PIP (384mg, 3.6mmol ), stirred at room temperature for 5 min, and monitored the end point of the reaction by TLC. A large amount of acetonitrile was added to the reaction solution to precipitate crystals, and the crystals were collected by filtration to obtain the product H-Asp(OtBu)-O-tag (2.73 g). The total yield of 1) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com