Device for monitoring spatial evaporation characteristic of micro-droplets in high-temperature airflow on line

A high-temperature airflow and micro-droplet technology, which is applied in the field of high-temperature devices for the evaporation of micro-droplets in scientific research, can solve the problems of insufficient reaction between flue gas and slurry in the tower, large fluctuation range, and less research on evaporation characteristics. Protection from high temperature damage, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

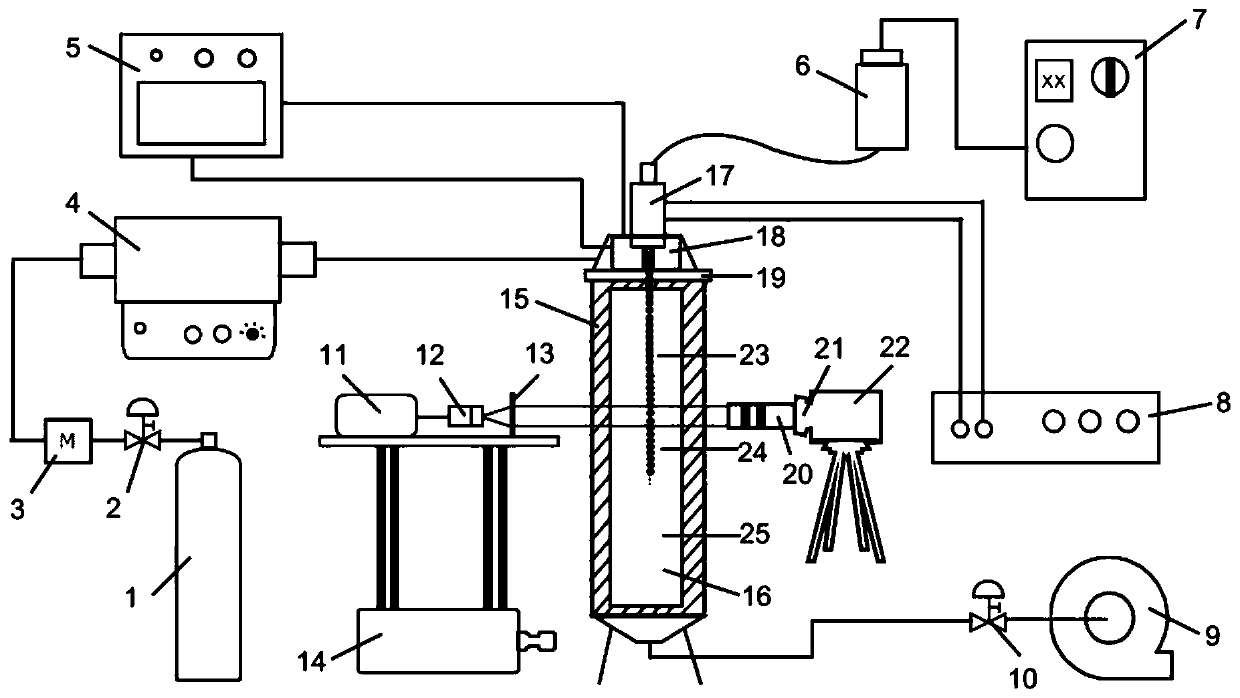

[0048] Such as figure 1 As shown, this embodiment provides a device for on-line monitoring of the space evaporation characteristics of micro-droplets in high-temperature airflow, the device includes an air intake system, a heating system, a temperature control system, a micro-droplet injection system, an amplified digital simultaneous Shaft holographic measurement system and cooling water circulation system. The specific structure is as follows:

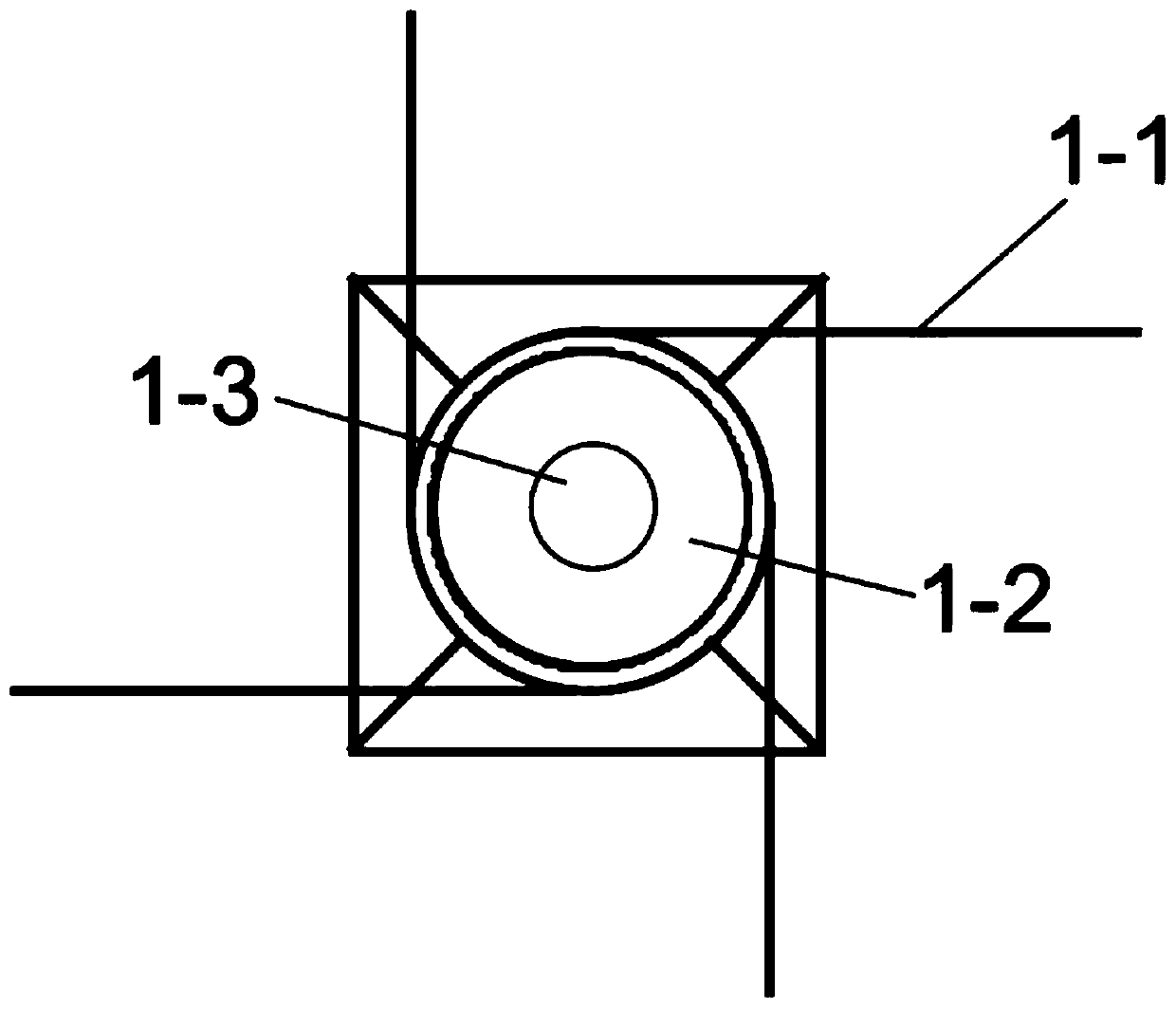

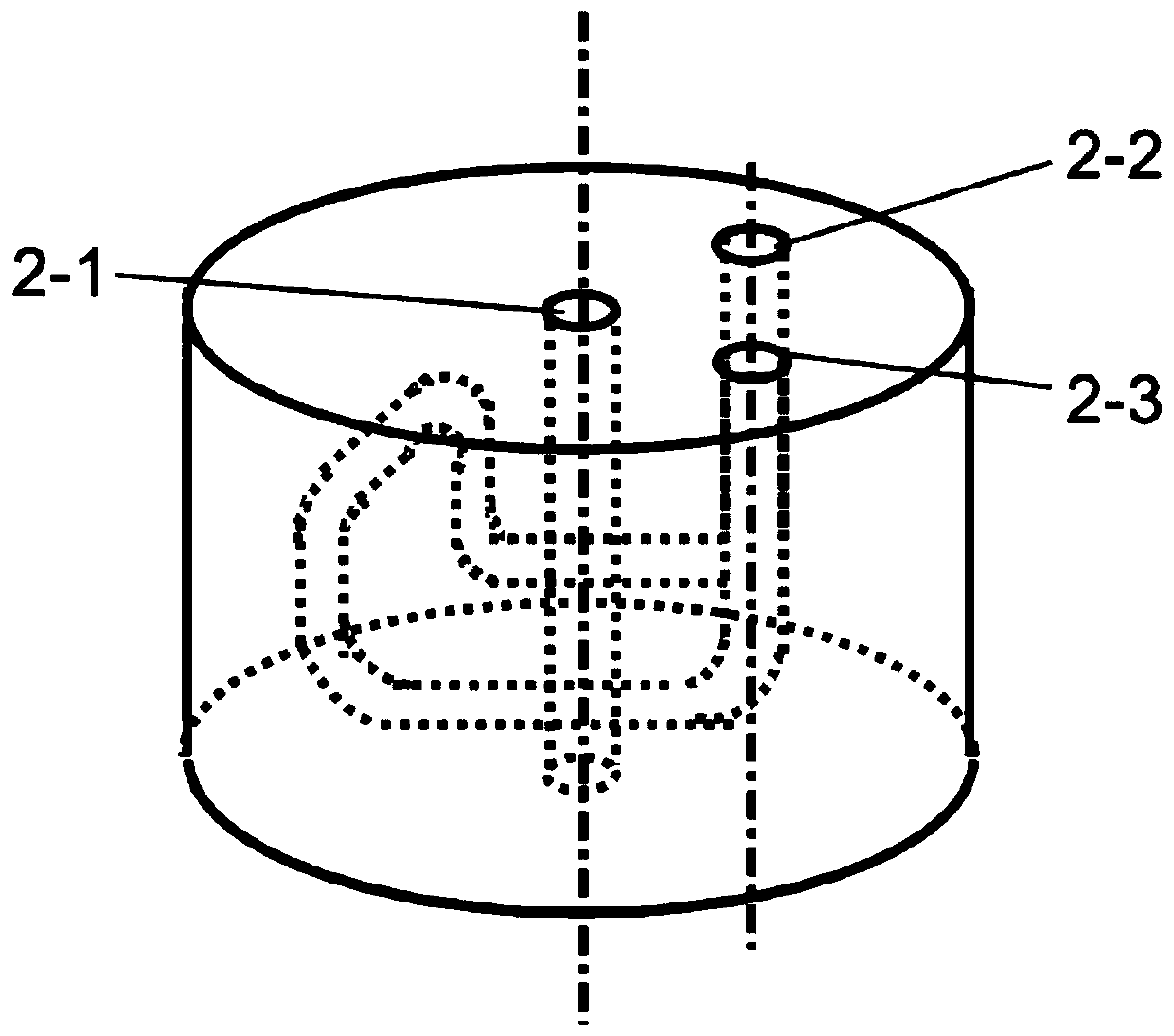

[0049] In the air intake system, it includes a gas cylinder 1, a pressure reducing valve 2, a gas electronic flowmeter 3, an industrial hot air blower 4, an induced draft fan 9, and an air volume regulating valve 10 installed at the entrance of the induced draft fan. The gas cylinder 1 is filled with Gas, the pressure reducing valve 2 is located on the gas discharge pipeline, the gas electronic flowmeter 3 is used to control the flow of the gas, and the industrial heater 4 is used to preheat the gas. Temperature setting and automat...

Embodiment 2

[0059] The device for on-line monitoring of the space evaporation characteristics of the micro-droplets in the high-temperature airflow of Example 1 is used, and the clear liquid of desulfurization wastewater is used as the test sample. The specific operation steps are as follows:

[0060] (1) Put the filtered desulfurization wastewater clear liquid in the liquid storage bottle, turn on the air pressure controller and the electric drive controller, and fix the nozzle at the through hole in the center of the cooling aluminum ingot.

[0061] (2) Open the cooling water tank 5 to circulate the cooling water to ensure that enough cooling water flows through the cooling aluminum ingot to protect the nozzle.

[0062] (3) Connect the gas pipeline, pass in the required gas, turn on the hot air blower 4, heat the inlet gas to the required preheating temperature, turn on the induced draft fan 9, and keep the furnace in a negative pressure state.

[0063] (4) Place the precision electric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com