Electrochemical aptamer sensor for quantitatively detecting ochratoxin A and application thereof

An aptamer sensor, ochratoxin technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve problems such as complex situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

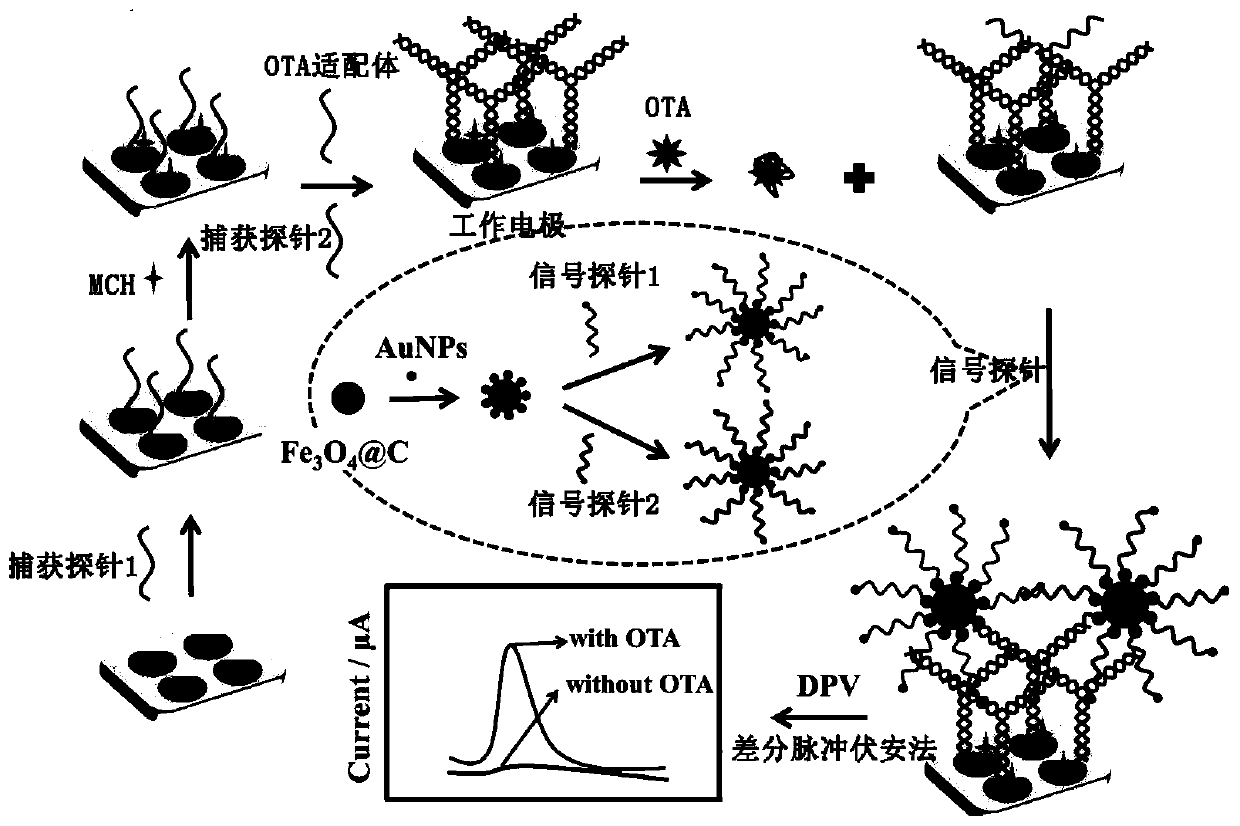

[0035] Example 1 Construction of an electrochemical aptasensor for quantitative detection of ochratoxin A

[0036] In the electrochemical aptamer sensor for quantitative detection of ochratoxin A of the present invention, the counter electrode is a platinum wire electrode, the reference electrode is a saturated calomel electrode, and the working electrode is sequentially modified reduced graphene oxide (RGO) on the surface of the gold sheet electrode. , molybdenum disulfide (MoS 2 ) and gold nanoparticles (AuNPs), capture probe 1, capture probe 2 and ochratoxin A aptamer. The construction method of the working electrode is described in detail below.

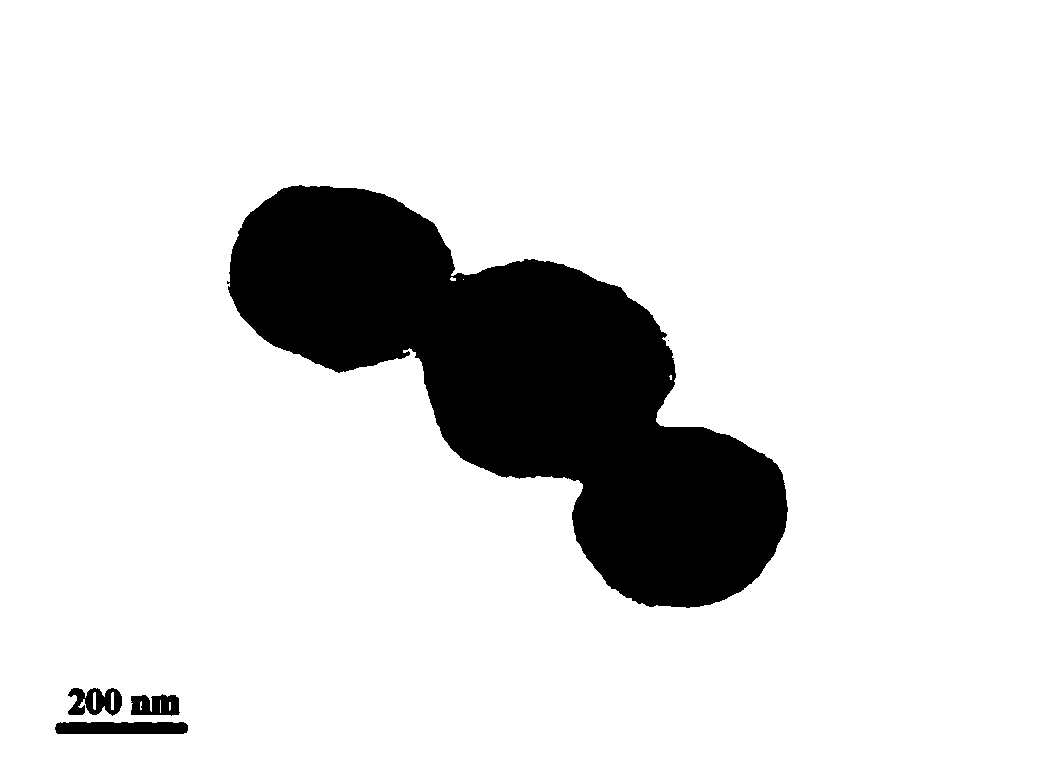

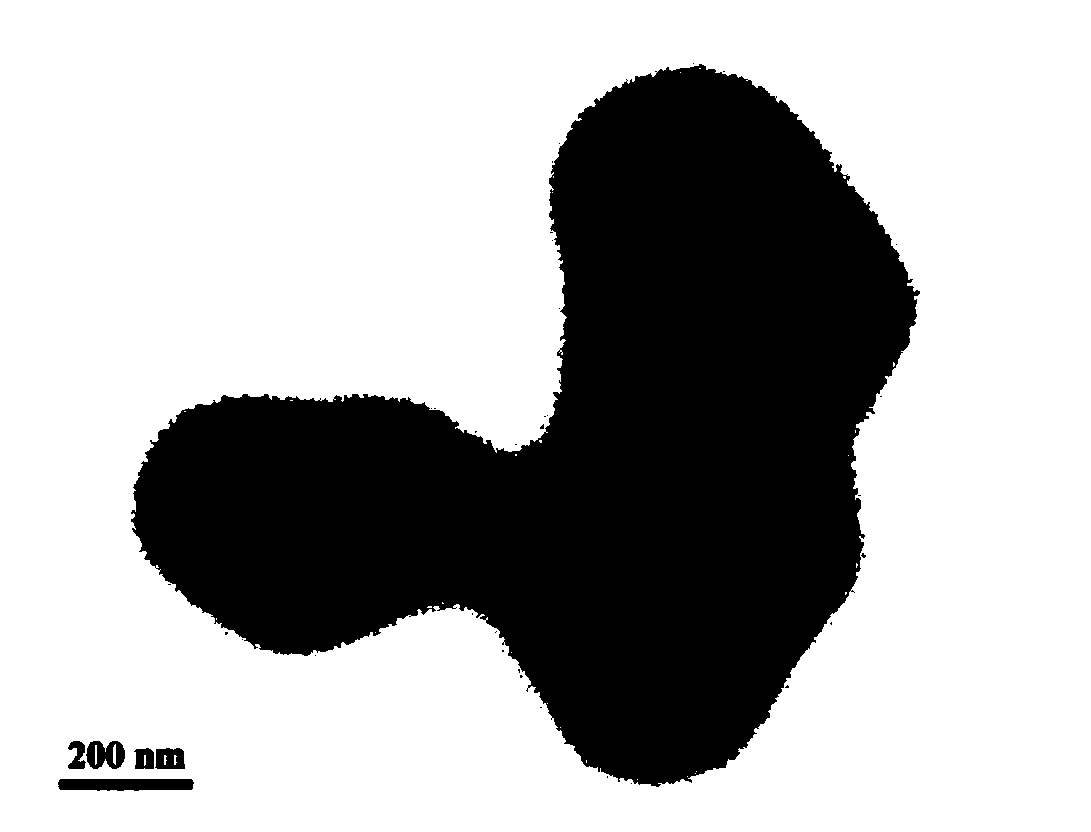

[0037] 1. Three-dimensional ordered porous RGO-MoS 2 -Construction of AuNPs electrode

[0038] Before use, the gold sheet was ultrasonically cleaned with acetone, ethanol, and pure water for 10 min, and then dried with nitrogen to obtain a clean gold electrode for future use.

[0039] Construction of 3DOM RGO-MoS 2 - The spe...

Embodiment 2

[0051] Example 2 Using an electrochemical aptasensor to detect OTA

[0052] The electrochemical aptasensor prepared in Example 1 was used to detect different concentrations of OTA solutions (1fg / mL-0.1μg / mL) to investigate the linear detection range and detection limit of the electrochemical aptasensor for OTA.

[0053] Electrolyte: 0.01M, pH 7.4 PBS buffer solution

[0054] Add the OTA solution with a concentration in the range of 1fg / mL-0.1μg / mL dropwise to the surface of the working electrode, react at 37°C for 40min, wash the surface of the working electrode with PBS, and the S1 / AuNPs-Fe obtained in Example 1 3 o 4 @C and S2 / AuNPs-Fe 3 o 4@C each took 10 μL dropwise onto the electrode surface, incubated at 37°C for 2 h, and then washed the electrode surface with PBS. After the above treatment, the working electrode, platinum wire electrode (counter electrode) and saturated calomel electrode (reference electrode) were placed in the electrolyte, and differential pulse vo...

Embodiment 3

[0055] The specificity of embodiment 3 electrochemical aptasensors

[0056] OTA, aflatoxin B1 (AFB1), aflatoxin B2 (AFB2), aflatoxin M1 (AFM1) and zearalenone (ZEN) solutions with a concentration of 0.01ng / mL were prepared using Example 1 respectively The electrochemical aptasensor was tested to investigate the specificity of the electrochemical aptasensor prepared in Example 1.

[0057] Electrolyte is with embodiment 2. Add the mycotoxin dropwise to the surface of the working electrode in the electrochemical aptamer sensor prepared in Example 1, react at 37°C for 40min, wash the surface of the working electrode with PBS, and the S1 / AuNPs-Fe obtained in Example 1 3 o 4 @C and S2 / AuNPs-Fe 3 o 4 @C each took 10 μL dropwise onto the electrode surface, incubated at 37°C for 2 h, and then washed the electrode surface with PBS. After the above treatment, the working electrode, platinum wire electrode (counter electrode) and saturated calomel electrode (reference electrode) were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com