Liquid material evaporation numerical simulation method in spray drying tower and storage medium

A technology of spray drying tower and numerical simulation, which is applied in the field of numerical simulation method and storage medium of liquid material evaporation in spray drying tower, which can solve the problem of inability to obtain the temporal and spatial distribution of flow parameters, limit the improvement and design of spray drying equipment, and limit petroleum refining, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

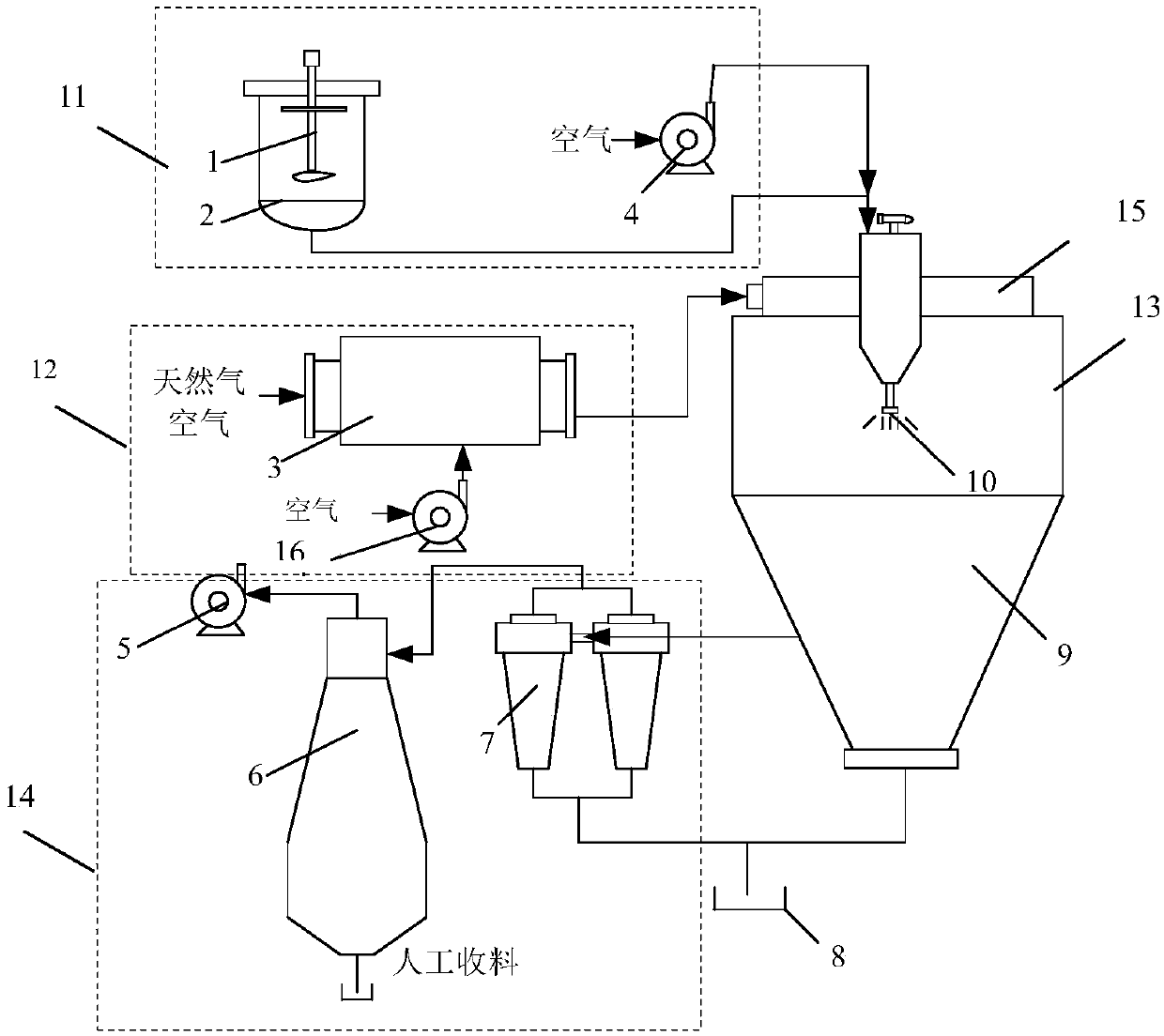

[0057] figure 1 It is a schematic diagram of the overall structure of the spray drying device provided by an embodiment of the present invention. The device includes: a feed liquid feeding device 11 for providing catalyst feed liquid. The feeding device includes: a stirring motor 1, a material storage tank 2 and a blower 4. The hot flue gas supply device 12 is used to provide hot flue gas. The gas supply device includes: the flue gas combustion chamber 3 and the blower 16; the spray drying tower 13 is used to receive the catalyst material provided by the feed liquid feeding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com