Rare earth metal modified Cu-SSZ-13 molecular sieve and preparation method and application thereof

A technology of cu-ssz-13 and rare earth metals, which is applied in the field of molecular sieve preparation and environmental pollution control, can solve problems such as insufficient hydrothermal stability, achieve good catalytic activity and nitrogen selectivity, improve high temperature hydrothermal stability, water Thermal stability and high space velocity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

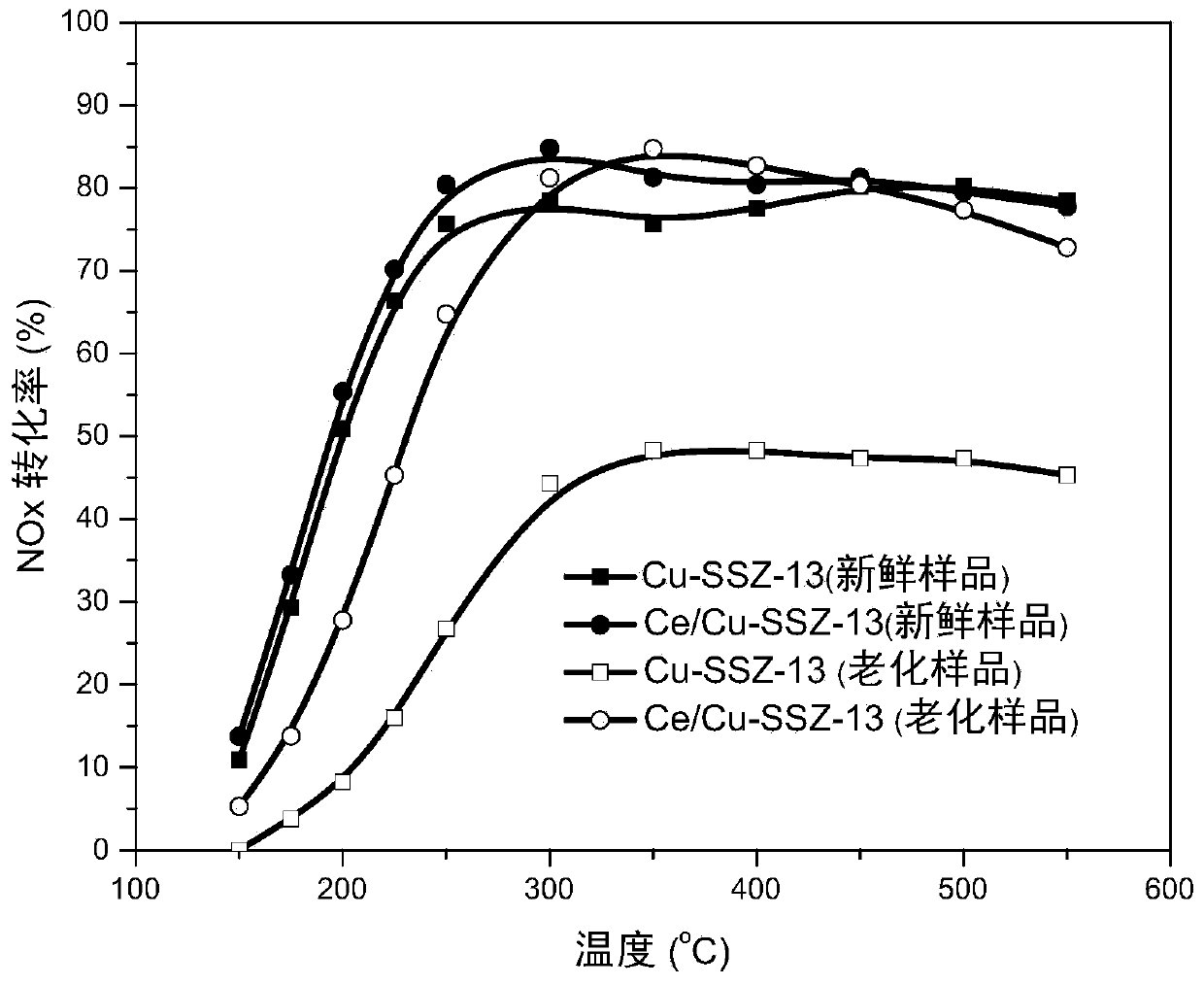

Embodiment 1

[0064] This example provides a method for modifying Cu-SSZ-13 molecular sieve with rare earth metal elements by ion exchange method, the prepared catalyst and its application. The specific steps of the method are as follows:

[0065] (1) A certain amount of Cu-SSZ-13 with a silicon-aluminum ratio of 4 synthesized by using Cu-TEPA as a template was added to the ammonium chloride solution with a concentration of 0.04mol / L, stirred in a water bath at 40°C for 5h, and the molecular sieve and chloride The solid-to-liquid ratio of the ammonium salt solution is 1g:40ml;

[0066] (2) After the ion exchange is completed, the obtained mixture is separated from solid and liquid, dried, and calcined at 600° C. for 6 hours to obtain Cu-SSZ-13 molecular sieve with moderate copper content;

[0067] (3) Place the molecular sieve obtained in step (2) in a 0.1mol / L cerium nitrate solution, and stir in a water bath at 80°C for ion exchange for 16 hours;

[0068] (4) After the ion exchange, the...

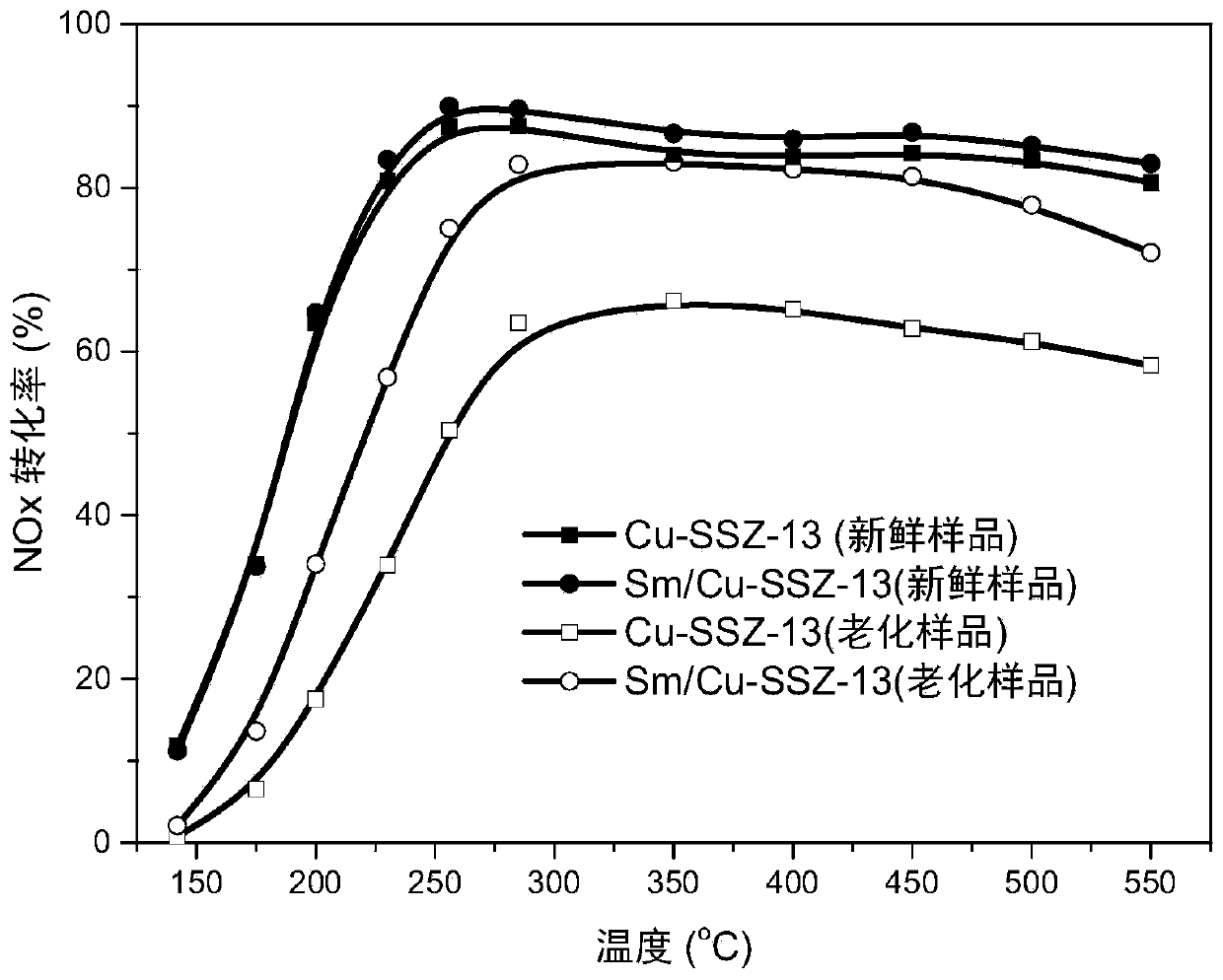

Embodiment 2

[0070]This embodiment provides a method for modifying a Cu-SSZ-13 molecular sieve with a rare earth metal element by an ion exchange method, a prepared catalyst and an application thereof. The specific steps of the method are as follows:

[0071] (1) A certain amount of Cu-SSZ-13 with a silicon-to-aluminum ratio of 4.2 synthesized by using Cu-TEPA as a template was added to an ammonium chloride solution with a concentration of 0.02 mol / L, and stirred in a water bath at 40 °C for 5 hours. The solid-liquid ratio of ammonium salt solution is 1g:40ml;

[0072] (2) After the ion exchange is completed, the obtained mixture is solid-liquid separated, dried, and calcined at 600° C. for 6 hours to obtain Cu-SSZ-13 molecular sieves with moderate copper content;

[0073] (3) placing the molecular sieve obtained in step (2) in a 0.1 mol / L samarium nitrate solution, and stirring in a water bath at 80° C. to perform ion exchange for 16 hours;

[0074] (4) After the ion exchange is complet...

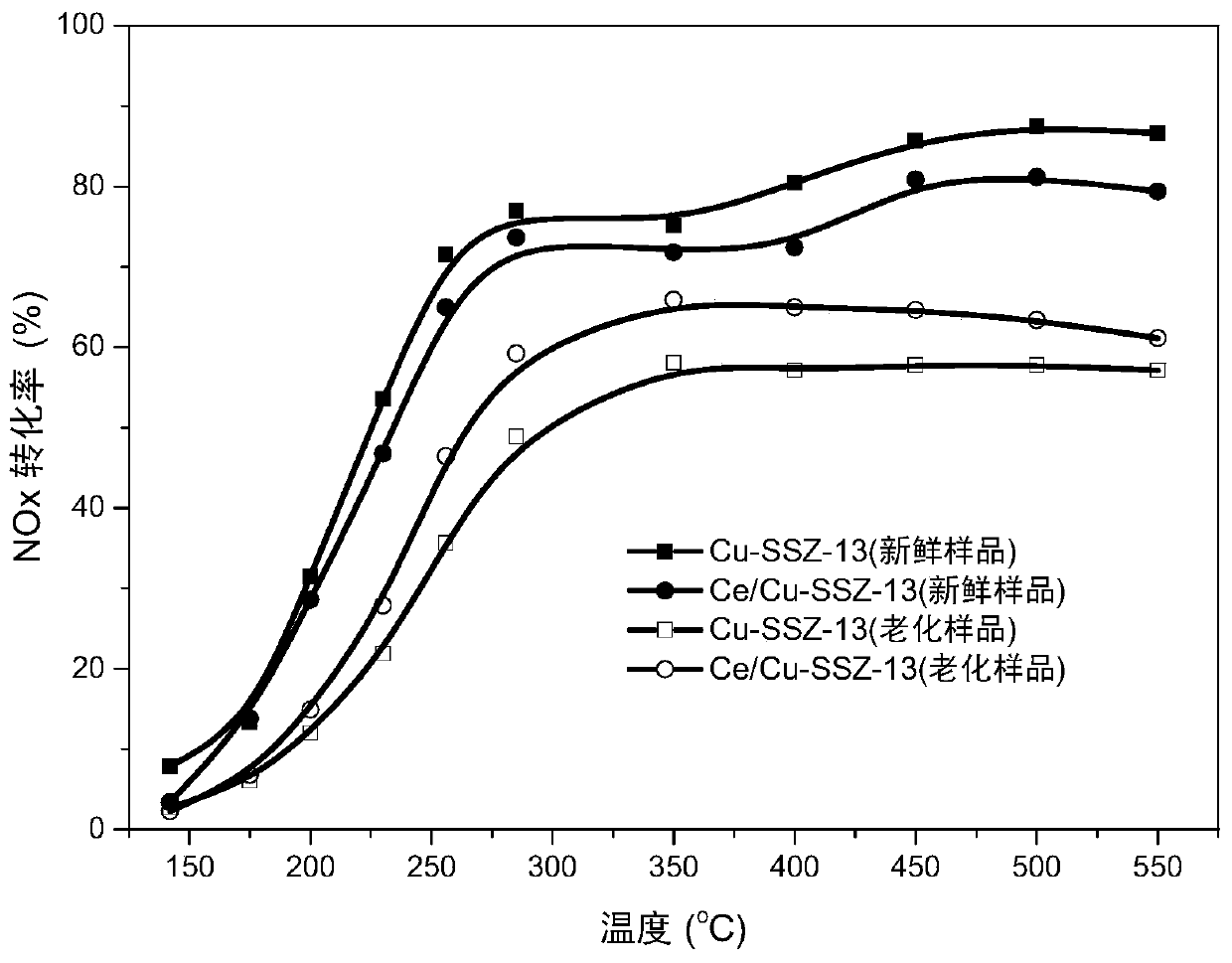

Embodiment 3

[0076] This embodiment provides a method for modifying a Cu-SSZ-13 molecular sieve with a rare earth metal element by an ion exchange method, a prepared catalyst and an application thereof. The specific steps of the method are as follows:

[0077] (1) A certain amount of Cu-SSZ-13 with a silicon-to-aluminum ratio of 5 synthesized by using Cu-TEPA as a template was added to a solution of ammonium chloride with a concentration of 0.015 mol / L, and stirred in a water bath at 40 °C for 5 hours. The solid-liquid ratio of ammonium salt solution is 1g:100ml;

[0078] (2) After the ion exchange is completed, the obtained mixture is solid-liquid separated, dried, and calcined at 600° C. for 6 hours to obtain Cu-SSZ-13 molecular sieves with moderate copper content;

[0079] (3) placing the molecular sieve obtained in step (2) in a 0.1 mol / L samarium nitrate solution, and stirring in a water bath at 80° C. for ion exchange for a duration of 16 hours;

[0080] (4) After the ion exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com