Butylbenzene modified zero-ammonia acrylic acid waterproof mortar emulsion and preparation method thereof, and waterproof mortar

A technology of zero-ammonia acrylic acid and waterproof mortar, which is applied in the field of waterproof mortar, zero-ammonia acrylic acid waterproof mortar emulsion and its preparation, and can solve the problem that the bonding strength and flexural compressive strength cannot reach the level of styrene-butadiene, flexibility and rigidity Balance is difficult to improve, flexibility and other issues are ignored, to achieve the effect of ensuring stability and reproducibility, convenient source, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

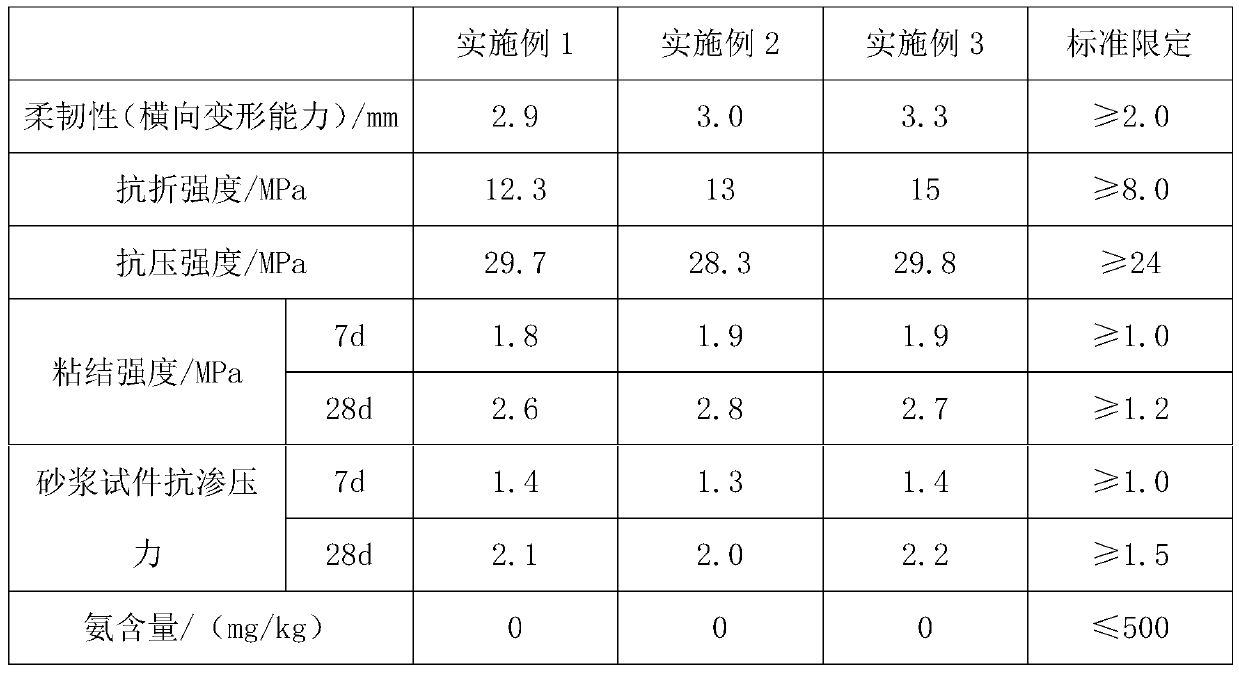

Examples

Embodiment 1

[0028] A butylbenzene-modified zero-ammonia acrylic acid waterproof mortar emulsion, comprising the following components in parts by weight: 100 parts of deionized water, 33 parts of styrene, 53 parts of butyl acrylate, 1.5 parts of hydroxyethyl acrylate, hydroxyethyl methacrylate 1.3 parts of ester, 2.8 parts of methacrylic acid, 0.1 part of allyl methacrylate, 0.1 part of silane coupling agent, 60 parts of styrene-butadiene emulsion, 2.1 parts of emulsifier, 0.2 parts of initiator, and 0.55 parts of sodium hydroxide.

[0029] The glass transition temperature of the styrene-butadiene emulsion is 8°C.

[0030] The emulsifier is a composite emulsifier formed by mixing an anionic emulsifier and a nonionic emulsifier at a mass ratio of 1:1.

[0031] The anionic emulsifier is sodium dodecyl diphenyl ether disulfonate, and the nonionic emulsifier is fatty alcohol polyoxyethylene ether.

[0032] The initiator is potassium persulfate.

[0033] The preparation method of the zero-amm...

Embodiment 2

[0040] A butylbenzene-modified zero-ammonia acrylic acid waterproof mortar emulsion, comprising the following components in parts by weight: 100 parts of deionized water, 35 parts of styrene, 51 parts of butyl acrylate, 5 parts of hydroxyethyl acrylate, and hydroxyethyl methacrylate 1 part of ester, 1.5 parts of methacrylic acid, 0.2 part of allyl methacrylate, 0.5 part of silane coupling agent, 65 parts of styrene-butadiene emulsion, 9 parts of emulsifier, 0.62 part of initiator, and 1.8 parts of sodium hydroxide.

[0041] The glass transition temperature of the styrene-butadiene emulsion is 10°C.

[0042] The emulsifier is a composite emulsifier formed by mixing an anionic emulsifier and a nonionic emulsifier at a mass ratio of 1.5:1.

[0043] The anionic emulsifier is sodium dodecylsulfonate, and the nonionic emulsifier is fatty alcohol polyoxyethylene ether.

[0044] The initiator is sodium persulfate.

[0045] The preparation method of the zero-ammonia acrylic acid wate...

Embodiment 3

[0052] A butylbenzene-modified zero-ammonia acrylic acid waterproof mortar emulsion, comprising the following components by weight: 100 parts of deionized water, 25 parts of styrene, 61 parts of butyl acrylate, 2.5 parts of hydroxyethyl acrylate, hydroxyethyl methacrylate 2.8 parts of ester, 0.8 part of methacrylic acid, 0.5 part of allyl methacrylate, 0.15 part of silane coupling agent, 55 parts of styrene-butadiene emulsion, 5.5 parts of emulsifier, 0.95 part of initiator, and 0.12 part of sodium hydroxide.

[0053] The glass transition temperature of the styrene-butadiene emulsion is 12°C.

[0054] The emulsifier is a composite emulsifier formed by mixing an anionic emulsifier and a nonionic emulsifier at a mass ratio of 5:1.

[0055] The anionic emulsifier is sodium dodecyl diphenyl ether disulfonate, and the nonionic emulsifier is fatty alcohol polyoxyethylene ether.

[0056] The initiator is sodium persulfate and potassium persulfate mixed in a mass ratio of 1:1.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com