Flammulina velutipes antifreeze polysaccharide, and preparation method and application thereof

A technology of Flammulina velutipes and Flammulina velutipes, applied in the direction of biochemical equipment and methods, applications, and methods based on microorganisms, which can solve the problems of nutrient loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

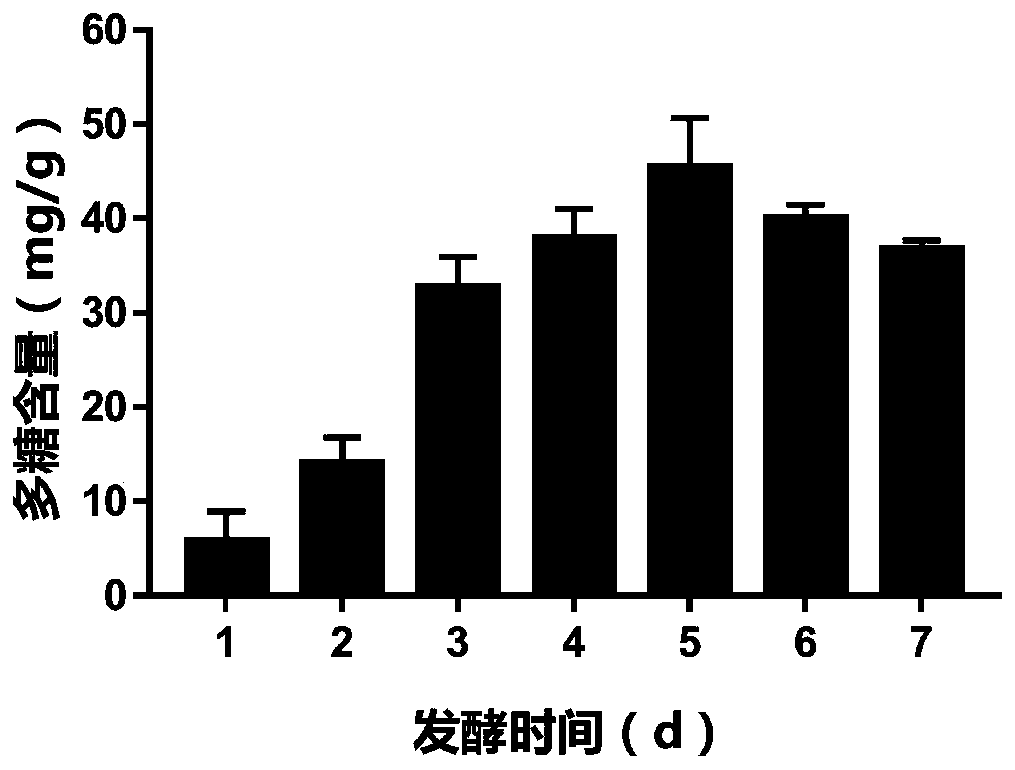

[0075] Embodiment 1: The influence of different fermentation time on the content of antifreeze polysaccharide produced by Flammulina velutipes

[0076] (1) Cultivation of Flammulina velutipes seeds: Take 3 pieces of hyphae of 4mm×4mm from the Flammulina velutipes plate and insert them into the seed medium. The culture temperature is 20° C., and the culture rotation speed is 180 rpm. The culture time is 5 days.

[0077] (2) Flammulina velutipes fermentation culture: the seed liquid was inserted into the fermentation medium, the inoculum size was 10%, the culture temperature was 18° C., and the culture time was 7 days. Samples were taken at different culture times, and the mycelium was subjected to low-temperature induction treatment.

[0078] (3) Cold treatment of Flammulina velutipes mycelium: the fermented Flammulina velutipes mycelium was put into a refrigerator at 4°C for cold treatment, and the cold treatment time was 7 days.

[0079] (4) Extraction of the antifreeze pol...

Embodiment 2

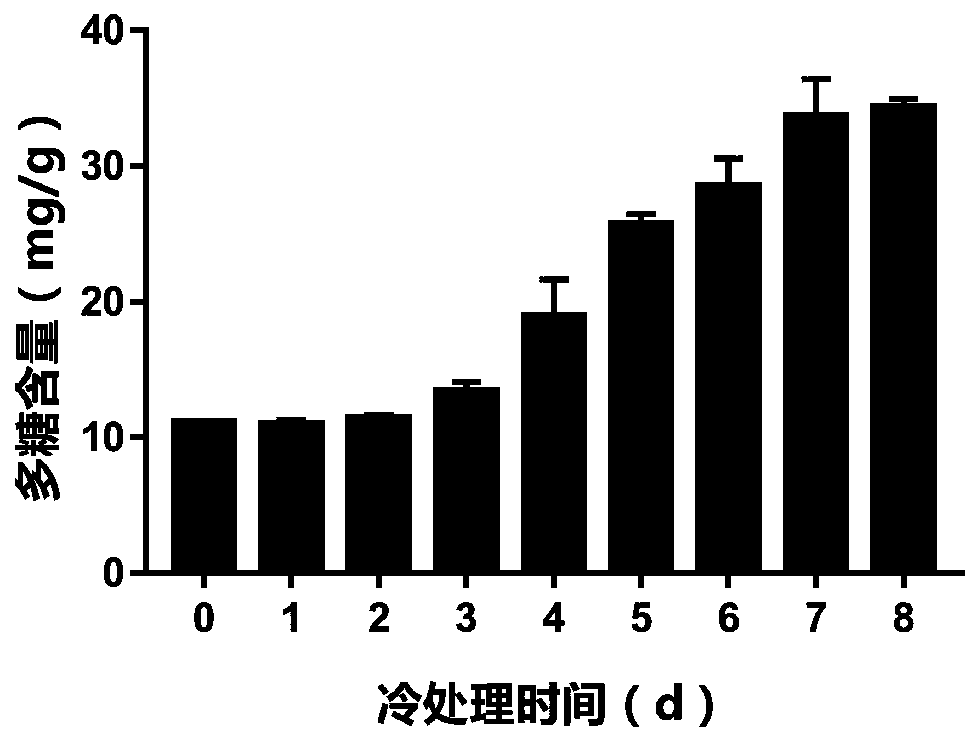

[0081] Embodiment 2: The influence of different cold treatment time on the antifreeze activity of Flammulina velutipes antifreeze polysaccharide

[0082] (1) Cultivation of Flammulina velutipes seeds: Take 3 pieces of hyphae of 4mm×4mm from the Flammulina velutipes plate and insert them into the seed medium. The culture temperature is 20° C., and the culture rotation speed is 180 rpm. The culture time is 5 days.

[0083] (2) Flammulina velutipes fermentation culture: insert the seeds into the fermentation medium, the inoculum size is 10%, the culture temperature is 18° C., and the culture time is 5 days.

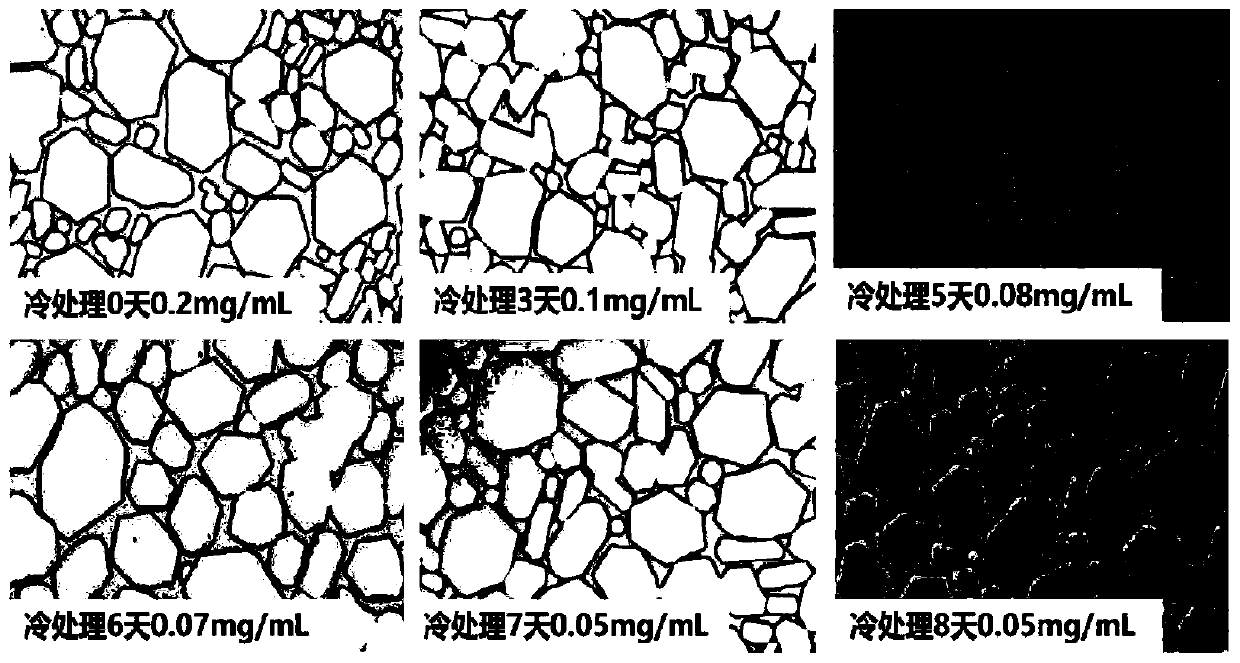

[0084] (3) Cold treatment of Flammulina velutipes mycelium: Put the fermented Flammulina velutipes mycelium into a refrigerator at 4°C for 8 days of cold treatment, and take samples at different cold treatment times.

[0085] (4) Extraction of Flammulina velutipes polysaccharide: the cold-treated Flammulina velutipes mycelium is filtered with gauze, washed with distilled w...

Embodiment 3

[0091] Embodiment 3: Application experiment of antifreeze polysaccharide

[0092] (1) 50g chicken, cut into chicken pieces of 5cm×5cm in size, add 20mL of polysaccharide solution with concentrations of 2.2μg / mL, 10μg / mL, and 100μg / mL respectively, act at 3°C for 24h, and then put it into -80°C for rapid freezing 2h, put them into polyethylene bags, seal them, and freeze them at -20°C for 7 days. After thawing at 4°C, centrifuge at 4000rpm / min for 10min, and weigh the chicken.

[0093] (2) Liquid output % of chicken = (weight of initial chicken - weight of chicken after centrifugation) / weight of initial chicken

[0094] Experimental results such as Figure 5 As shown, compared with the control group, the liquid output of the chicken added with Flammulina velutipes polysaccharides was reduced to a certain extent, and the liquid output of chickens added with 100 μg / mL Flammulina velutipes polysaccharides was significantly different from that of the control group. Therefore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com