Adaptive evolution method for gluconobacter oxydans efficiently utilizing non-glucose carbon sources and application of adaptive evolution method

A technology of Gluconobacter oxydans and adaptive evolution, applied in the fields of biotechnology and microorganisms, can solve the problems of affecting the production efficiency of sugar acid, low utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

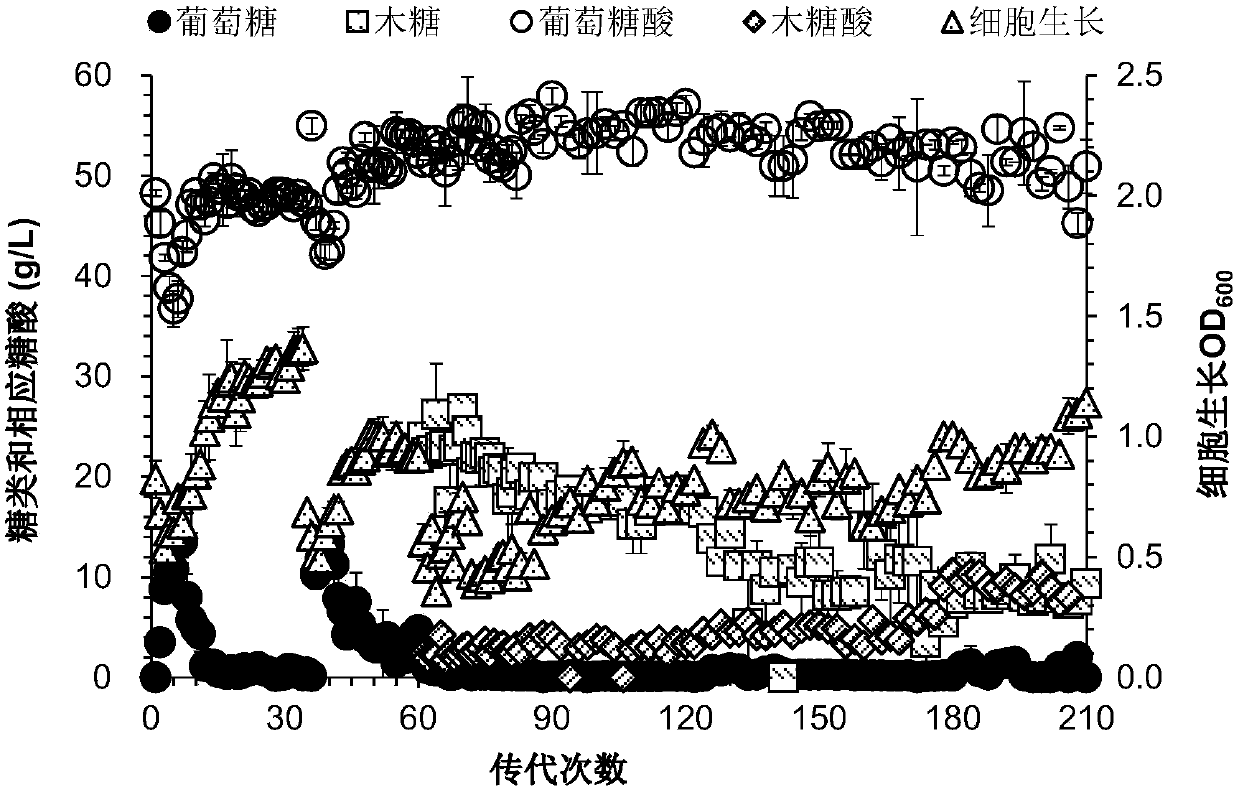

[0016] Example 1 strain screening

[0017] Under sterile conditions, the parent strain of Gluconobacter oxidans was inoculated into the detoxified corn stalk hydrolyzate, and cultured at 30°C and 220rpm for 24 hours. The fermentation pH changed from a certain amount of CaCO 3 maintenance; then insert 10% inoculum into the non-detoxified corn stalk hydrolyzate and culture for 24 hours under the same conditions, and then alternately transfer in the detoxified and non-detoxified hydrolyzate until the fermentation performance of the strain is significantly improved and maintained Stablize. The obtained strain has been named Gluconobacter oxydans RM7, and was deposited in the General Microorganism Center (CGMCC) of the China Committee for the Collection of Microbial Cultures (CGMCC) on October 11, 2017, with the preservation number CGMCC No.14801.

Embodiment 2

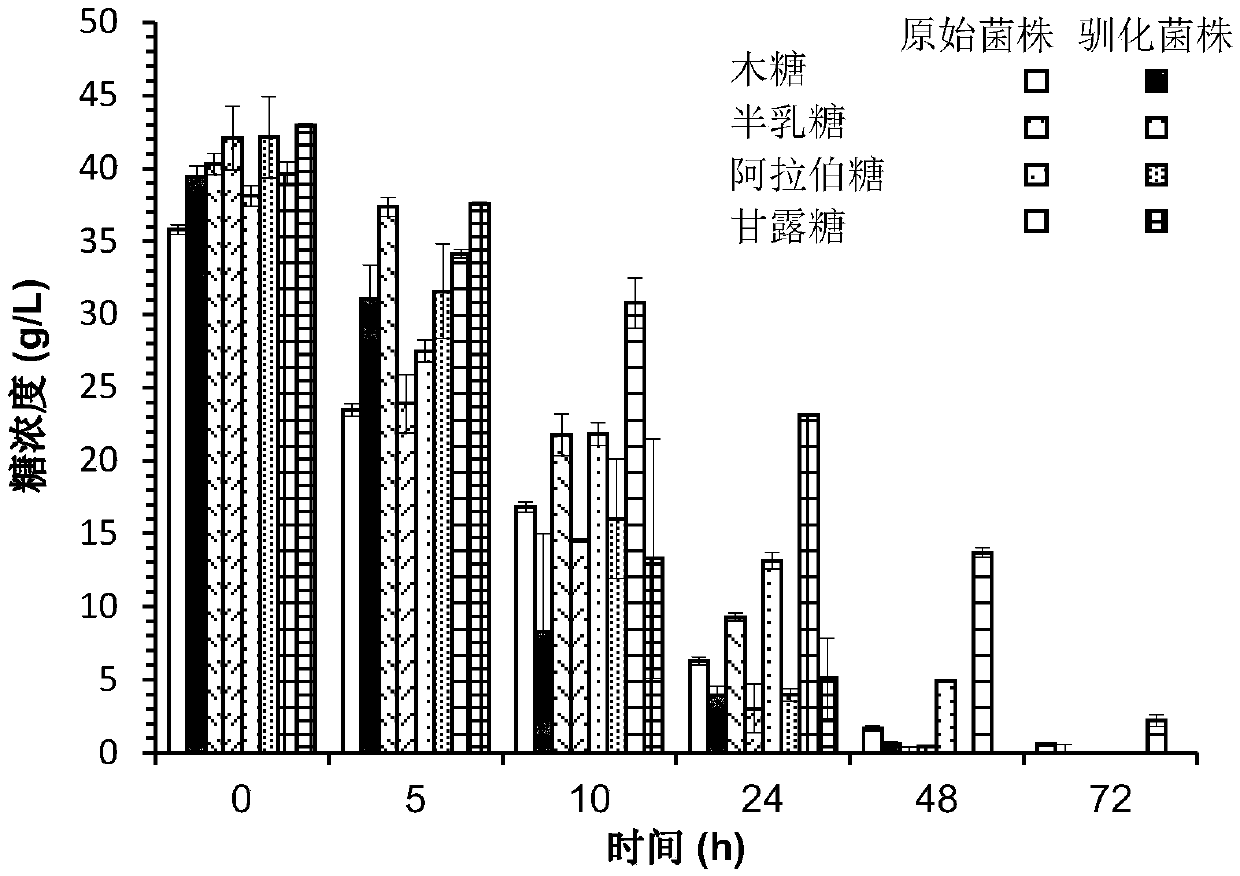

[0018] The utilization of embodiment 2 bacterial strain to single carbon source

[0019] Adaptive evolution of new strains to the utilization of a single carbon source was investigated in a synthetic medium. The initial sugar concentration is 40g / L, the nutrient salt component is 10.0g / L yeast extract, 1.5g / L KH 2 PO 4 ,1.5g / L(NH 4 ) 2 SO 4 and 0.5g / LMgSO 4 7H 2 O. The culture condition is 50mL system cultured at 200rpm and 30°C for 72h. The analysis results showed that the single carbon source utilization efficiency of the adaptive evolutionary strains was improved compared with the original strains.

Embodiment 3

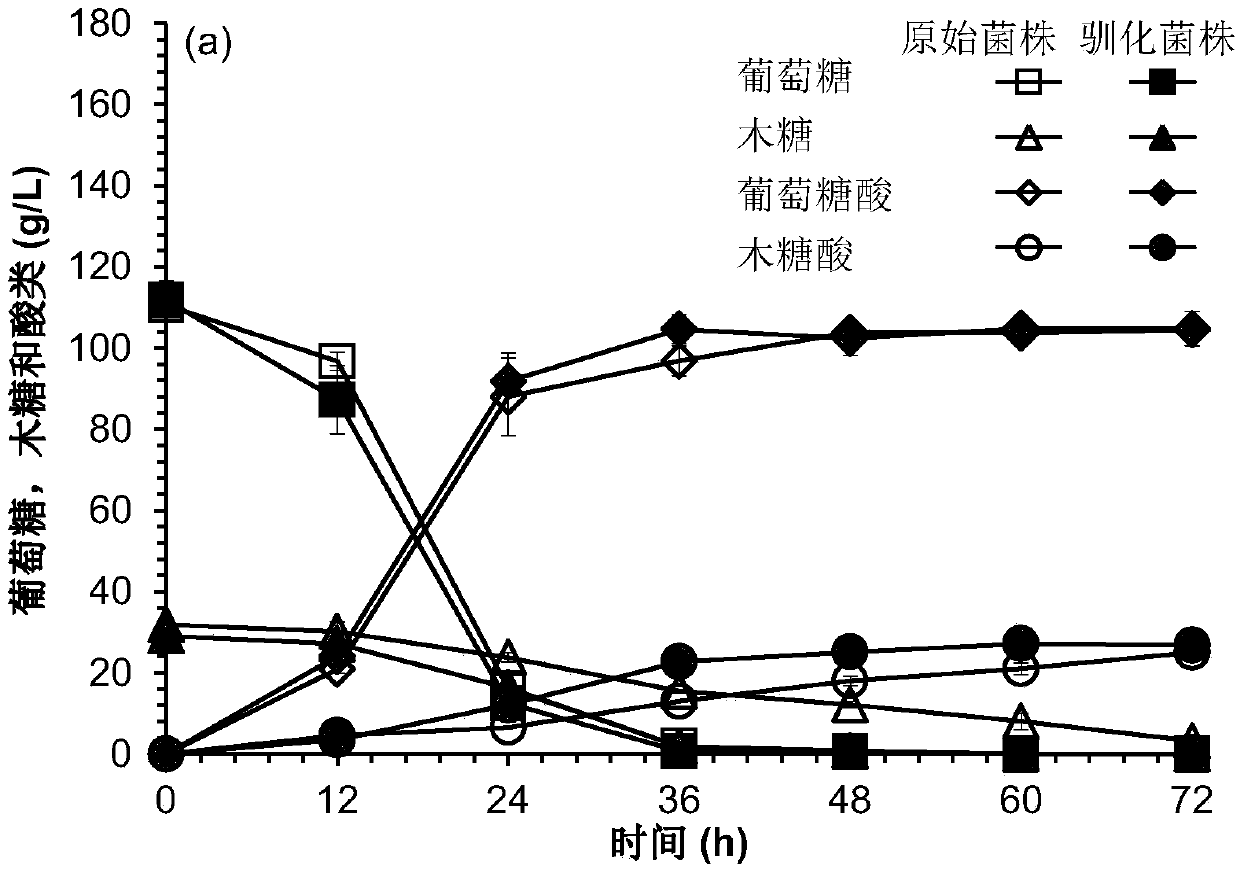

[0020] Example 3 Bacterial Strain Utilization of Total Sugar from Hydrolyzate

[0021] The domesticated strains were also tested for fermentation in hydrolyzate. Fermentation was carried out in a 5L reactor, the fermentation conditions were 30% solid content, 4mg enzyme protein / g dry material, 500rpm, 35°C, aeration rate 1vvm and pH 4.8. The sugar-acid fermentation is directly carried out under the condition of fully saccharified and hydrolyzed mash without solid-liquid separation. The analysis results showed that similar to the single carbon source synthetic medium fermentation, the utilization of all non-glucose carbon sources in the hydrolyzate was significantly improved, especially mannose, which is difficult to utilize in the hydrolyzate, and the original The strain needs to be cultured at a high density to achieve complete conversion of mannose, while the adaptive evolution strain can convert most of the mannose within 72 hours of fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com