Preparation method for bamboo shoot nutrition powder

A technology for nutritional powder and bamboo shoots, applied in the fields of fruit and vegetable preservation, food science, food preservation, etc., can solve the problems affecting the enthusiasm of bamboo shoot farmers and processing enterprises, low price of fresh bamboo shoots, poor quality of bamboo shoot powder, etc. The effect of strong aroma and less processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

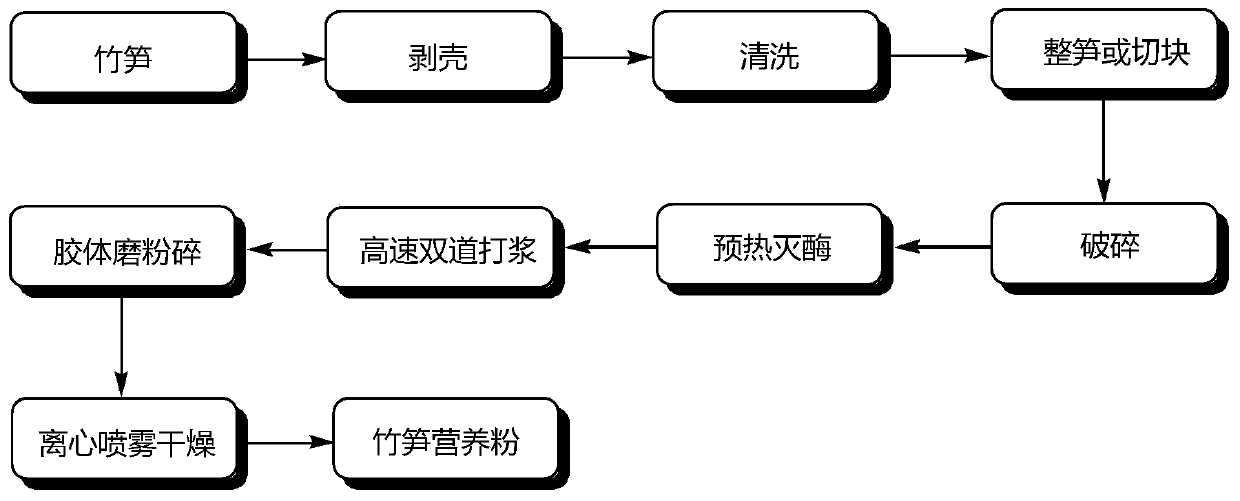

[0025] The invention provides a kind of preparation method of bamboo shoot nutrient powder, comprises the steps:

[0026] 1) crushing: crushing fresh bamboo shoots to obtain wet granules;

[0027] 2) Preheating to kill enzymes: preheating wet granules to get enzyme-killing wet granules, the temperature of the preheating to kill enzymes is 70-95°C, and the time is 1-3 minutes;

[0028] 3) beating: beat the enzyme-inactivated wet granules to obtain a beating liquid, and the dietary fiber particles after beating are less than 40 mesh;

[0029] 4) Pulverization: pulverize the beating liquid for 1 to 3 times;

[0030] 5) Drying: drying the pulverized slurry to obtain bamboo shoot nutritional powder.

[0031] The preparation method of bamboo shoot nutrition powder provided by the present invention preferably includes a pretreatment process: fresh bamboo shoots are shelled, cleaned, and cut into bamboo shoot pieces with a maximum length of 10 cm, and more preferably cut into 2 to 4...

Embodiment 1

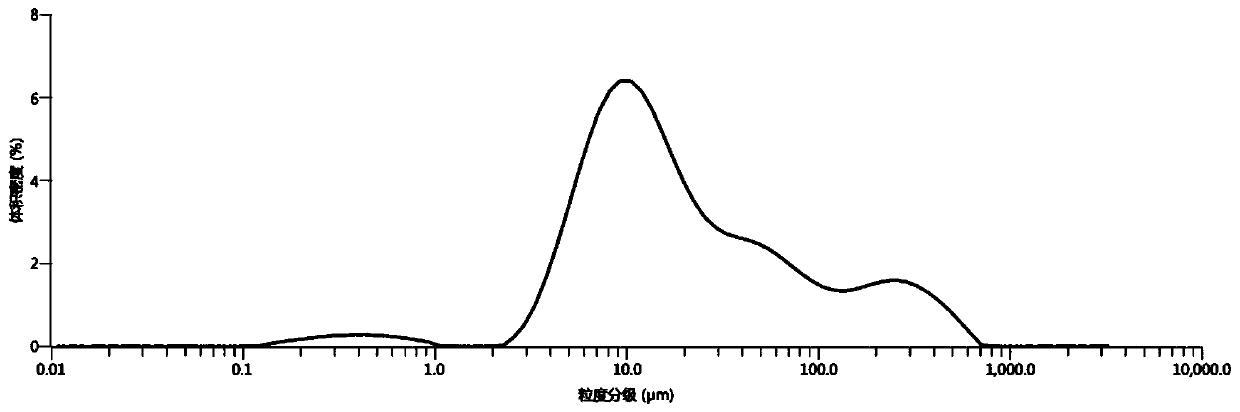

[0047] Preparation of moso bamboo shoot nutrition powder: pick fresh spring bamboo shoots of moso bamboo, after shelling and cleaning, take 1000.0 kg of raw bamboo shoots and add them to a crusher for crushing to obtain 950.0 kg of wet particles of 8 mm. At a temperature of 90°C, after preheating the pipeline for 1.5 minutes to kill the enzyme, it is added to a double-channel beater for beating. The motor speed is 1470 rpm. The sieve aperture is 0.5 mm, and 930.0 kg of beating liquid is obtained. Pass the beating liquid through the colloid mill and continue pulverizing once to obtain 920.0 kg of finer slurry, which is poured into a storage tank with stirring function, and the stirring paddle is turned on. Finally, send the beating liquid in the storage tank into the centrifugal spray dryer with a pump, the flow rate is 100kg / h, the inlet air temperature is 190°C, and the outlet air temperature is 80°C, and 86.5kg of dried bamboo shoot nutrient powder is collected , and the yi...

Embodiment 2

[0050] Preparation of thunder bamboo shoot nutrition powder: fresh bamboo shoots were picked, shelled and cleaned, and 200.0 kg of raw bamboo shoots were added to a crusher for crushing to obtain 185.0 kg of 6mm wet particles. At a temperature of 90°C, after preheating the pipeline to kill enzymes for 2 minutes, put it into a double-channel beater for beating. The motor speed is 1480 rpm. The mesh diameter is 0.4 mm, and 180.0 kg of beating liquid is obtained. Pass the beating liquid through the colloid mill and continue pulverizing once to obtain 178 kg of finer slurry, which is poured into a storage tank with stirring function, and the stirring paddle is turned on. Finally, the beating liquid in the storage tank is sent into the centrifugal spray dryer with a pump, the flow rate is 80kg / h, the air inlet temperature is 185°C, and the air outlet temperature is 85°C, and 17.5kg of dried bamboo shoot nutrient powder is collected , and the yield was 8.75%.

[0051] Thunder bamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com