Peroxide catalytic oxidation catalyst, and method for treating epoxypropane and styrene coproduction wastewater by using same

A technology of catalytic oxidation and peroxide, applied in organic compound/hydride/coordination complex catalysts, oxidized water/sewage treatment, physical/chemical process catalysts, etc., can solve difficult process safety and stability, oxygen generation Large amount, long reaction time and other problems, to achieve the effect of high thermodynamic stability, low cost of use, and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

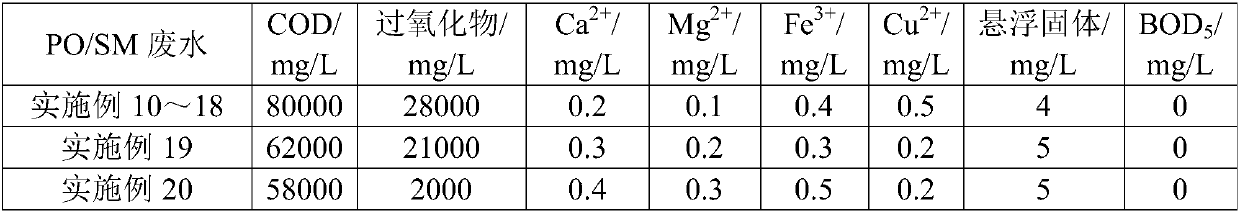

Examples

Embodiment 1

[0056] Embodiment 1: the preparation of 1# catalyst

[0057] Take 20g of the dried sludge sample and place it in a dipping bottle for vacuum pretreatment. The vacuum pretreatment time is 60min, and the vacuum degree is 98.0KPa (gauge pressure); 2 0.20g / mL methanol solution 1.0mL, containing CholineCl-NiCl 2 Add 1.4 mL of 0.15 g / mL methanol solution to methanol aqueous solution with a methanol concentration of 10 wt % to prepare an impregnation solution with a total volume of 20 mL. Add the above impregnation liquid into the vacuum impregnation bottle equipped with the above dried sludge carrier and mix evenly, impregnate the above dried sludge carrier with equal volume, after immersion for 30 minutes, take it out and dry it in an oven at 150°C for 5 hours, Then it was calcined at 400° C. for 5 hours in a muffle furnace to obtain 1# catalyst.

[0058] In the 1# catalyst of gained, take the weight of dried sludge wherein as basis, the content of following composition is as f...

Embodiment 2

[0059] Embodiment 2: the preparation of 2# catalyst

[0060] Get dried sludge sample 20g and place in dipping bottle, carry out vacuum pretreatment, vacuum pretreatment time is 10min, and vacuum degree is 96.0KPa (gauge pressure); Add it into an ethanol aqueous solution with an ethanol concentration of 10 wt%, and prepare an impregnation solution with a total volume of 20.0 mL. Add the above impregnating solution into the vacuum impregnation bottle with dried sludge carrier and mix evenly, then impregnate the above dried sludge carrier with an equal volume. After soaking for 30 minutes, take it out and dry it in an oven at 150°C for 5 hours, and then put it in the Roast at 400°C for 5 hours in a muffle furnace to prepare the cerium-modified dry sludge carrier. In the prepared cerium-modified dried sludge carrier, the content of cerium is 1.0wt% based on the weight of dried sludge.

[0061] Get above-mentioned cerium modified dry sludge sample 20g and place in dipping bottle,...

Embodiment 3

[0063] Embodiment 3: the preparation of 3# catalyst

[0064] Get dried sludge sample 20g and place in dipping bottle, carry out vacuum pretreatment, vacuum pretreatment time is 10min, and vacuum degree is 96.0KPa (gauge pressure); Add it into an ethanol aqueous solution with an ethanol concentration of 10 wt%, and prepare an impregnation solution with a total volume of 20.0 mL. Add the above impregnating liquid into the vacuum impregnation bottle equipped with the dried sludge carrier and mix evenly, then impregnate the above dried sludge carrier with equal volume. After soaking for 240min, take it out and dry it in an oven at 60°C for 1h, and then put it in the Roast at 300°C for 3 hours in a muffle furnace to prepare a cerium-modified dry sludge carrier. In the prepared cerium-modified dried sludge carrier, the content of cerium is 1.0wt% based on the weight of dried sludge.

[0065]Get above-mentioned cerium modified dry sludge sample 20g and place in dipping bottle, carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com