Preparation method of energy-saving anti-ultraviolet polytrimethylene terephthalate

A technology of propylene phthalate and purified terephthalic acid, which is applied in the field of preparation of energy-saving and UV-resistant polytrimethylene terephthalate, can solve the problems of precipitation and poor catalyst dispersion ability, and achieves lower polymerization temperature and better resistance to UV performance, the effect of reducing energy usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

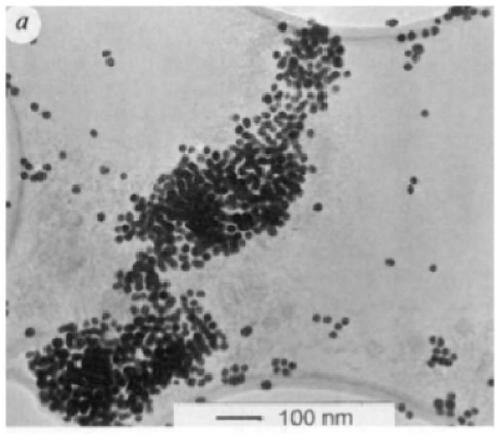

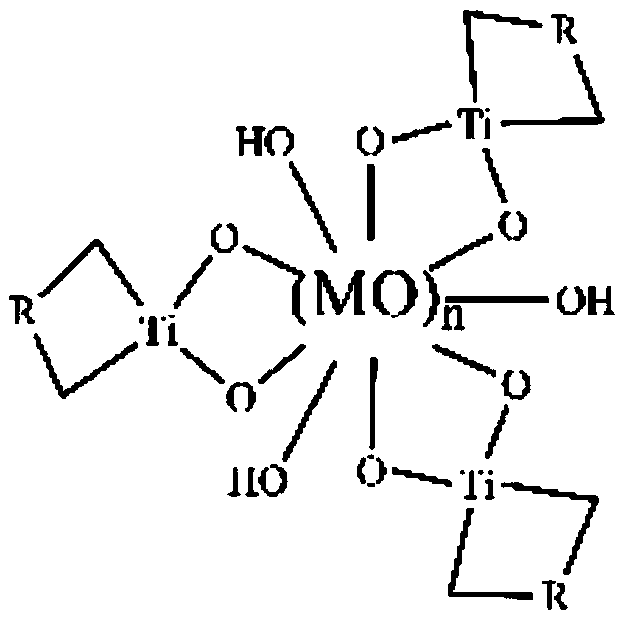

Image

Examples

Embodiment 1

[0032] The first stage of esterification reaction: Add 432g of purified terephthalic acid, 360g of propylene glycol, 0.26g of titanium-based catalyst loaded with metal ions, 0.26g of stabilizer, 0.23g of polyol and 2g of nano-titanium nitride slurry into the polymerization kettle reaction. Replace the air in the polymerization tank with inert gas, control the pressure in the polymerization tank at 0.3MPa, the speed of the agitator at 80r / min, control the temperature in the polymerization tank at 180°C, calculate the esterification efficiency by the water yield, when the conversion of terephthalic acid When the rate reaches 95%, the esterification reaction ends;

[0033]The second stage polycondensation reaction: vacuumize the polymerization kettle, control the pressure inside the polymerization kettle at 1.3KPa, raise the temperature inside the polymerization kettle to 230°C, control the rotation speed of the agitator at 120r / min, and react for 20min; The temperature was rais...

Embodiment 2

[0036] The first stage of esterification reaction: Add 432g of purified terephthalic acid, 300g of propylene glycol, 0.35g of titanium-based catalyst loaded with metal ions, 0.3g of stabilizer, 0.3g of polyol and 2.5g of nano-titanium oxide slurry into the polymerization kettle reaction. Replace the air in the polymerization tank with inert gas, control the pressure in the polymerization tank at 0.2MPa, the speed of the agitator at 80r / min, control the temperature in the polymerization tank at 210°C, calculate the esterification efficiency by the water yield, when the conversion of terephthalic acid When the rate reaches 98%, the esterification reaction ends;

[0037] The second stage polycondensation reaction: evacuate the polymerization kettle, control the pressure inside the polymerization kettle at 1.21KPa, raise the temperature inside the polymerization kettle to 240°C, control the rotation speed of the stirrer at 120r / min, and react for 25min; Raise to 260°C, control th...

Embodiment 3

[0040] The first stage of esterification reaction: Add 400g of purified terephthalic acid, 340g of propylene glycol, 0.2g of titanium-based catalyst loaded with metal ions, 0.2g of stabilizer, 0.25g of polyol and 1.5g of nano-titanium oxide slurry into the polymerization kettle reaction. Replace the air in the polymerization tank with inert gas, control the pressure in the polymerization tank at 0.1MPa, the speed of the agitator at 70r / min, control the temperature in the polymerization tank at 200°C, calculate the esterification efficiency by the water yield, when the conversion of terephthalic acid When the rate reaches 93%, the esterification reaction ends;

[0041] The second stage of polycondensation reaction: vacuumize the polymerization tank, control the pressure in the polymerization tank to 1.2KPa, raise the temperature in the polymerization tank to 230°C, control the rotation speed of the agitator at 120r / min, and react for 10-30min; then polymerize The temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com