Double fluidized bed pyrolysis combustion waste heat utilization system and method

A technology of double fluidized bed and circulating fluidized bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

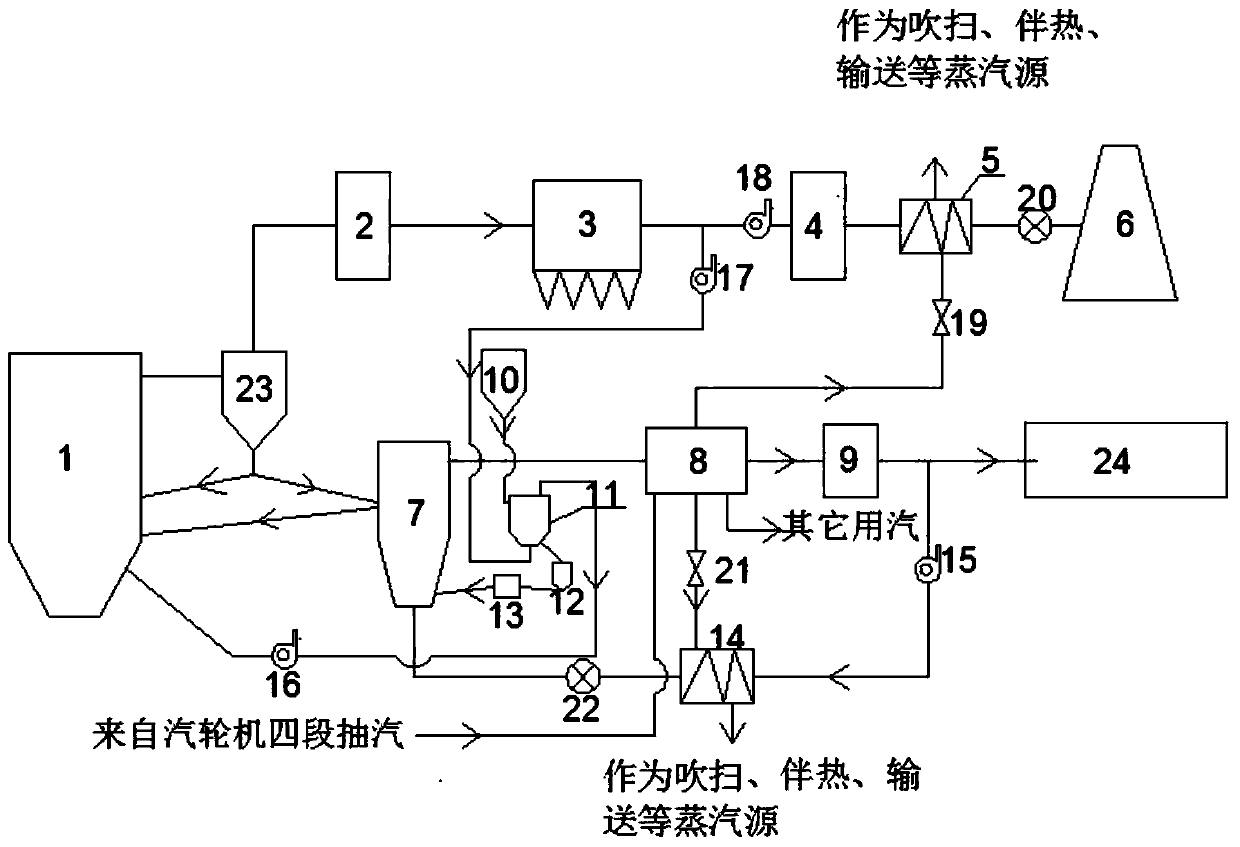

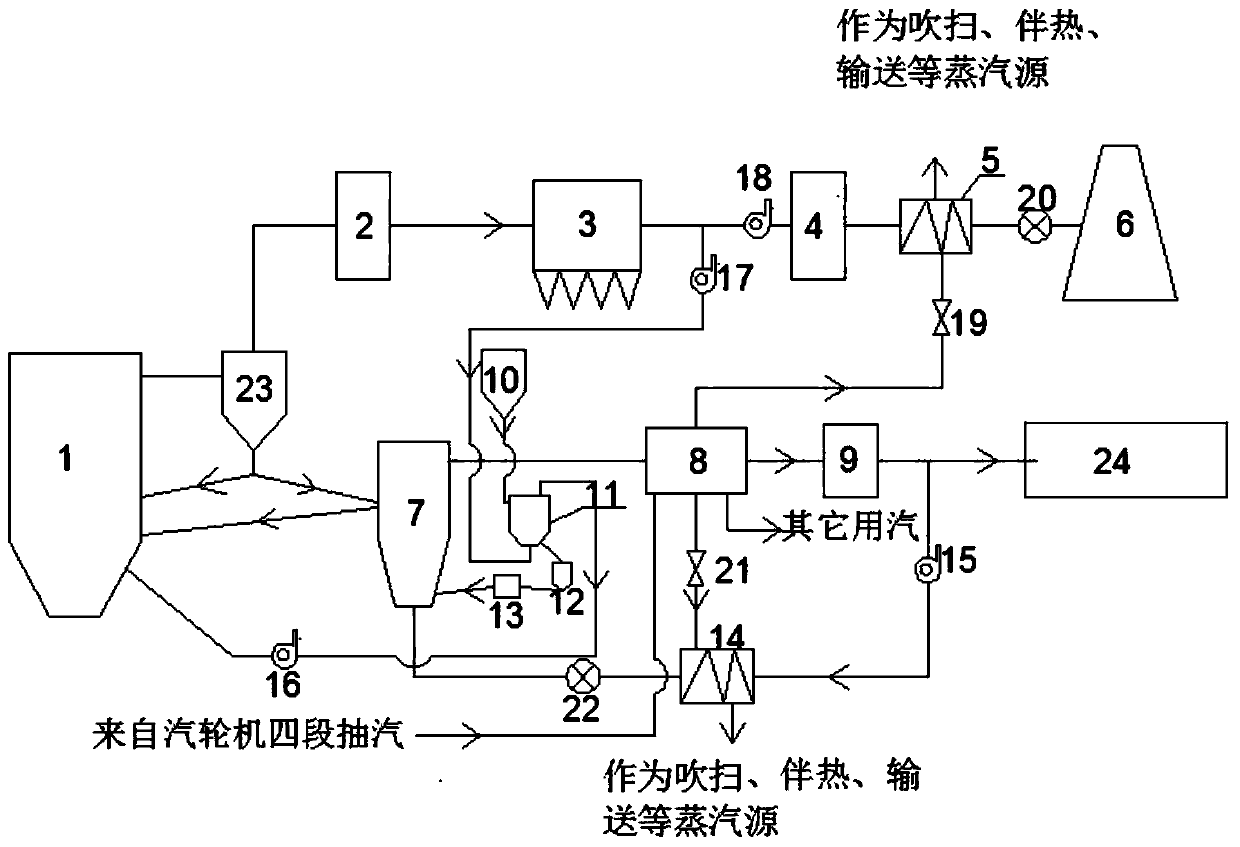

[0034] like figure 1 As shown, a dual fluidized bed pyrolysis combustion waste heat utilization system in this embodiment includes a circulating fluidized bed power generation system and a coal pyrolysis system; the circulating fluidized bed power generation system consists of a boiler 1, a separator 23, The air preheater 2, the dust remover 3, the desulfurization tower 4, the first steam-gas heat exchanger 5 and the chimney 6 are composed, the separator 23 is a cyclone separator, the flue gas outlet of the boiler 1 and the flue gas of the separator 23 The gas inlet is connected through a pipeline, the ash outlet of the separator 23 is connected with the furnace of the boiler 1 through a pipeline, the flue gas outlet of the separator 23 is connected with the flue gas inlet of the air preheater 2 through a pipeline, and the air preheater The flue gas outlet of 2 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com