An improved method for the preparation of ion beam sputtering coating plugging sensor

An ion beam sputtering and sensor technology, which is applied in sputtering coating, ion implantation coating, welding equipment, etc., can solve the problems of random sensor breaking position, lower production efficiency and product quality, and lower product reliability. Achieve the effects of resistance consistency and controllability of breaking position, production efficiency and product quality, performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and two embodiments.

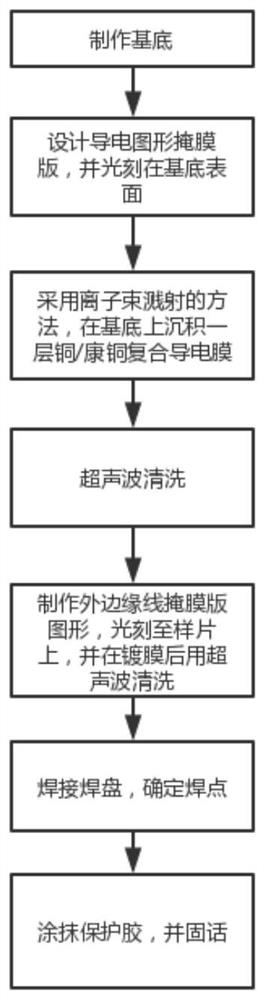

[0036] Such as figure 1 As shown, the present invention provides an improved method for preparing an ion beam sputtered film-coated blocking sensor, and the present invention further designs a positioning hole for a welding lead wire and a positioning hole for a breaking position. And in the film deposition process design of the conductive pattern, a new film structure design of a layer of copper and constantan is deposited. Its specific implementation is as figure 1 Shown:

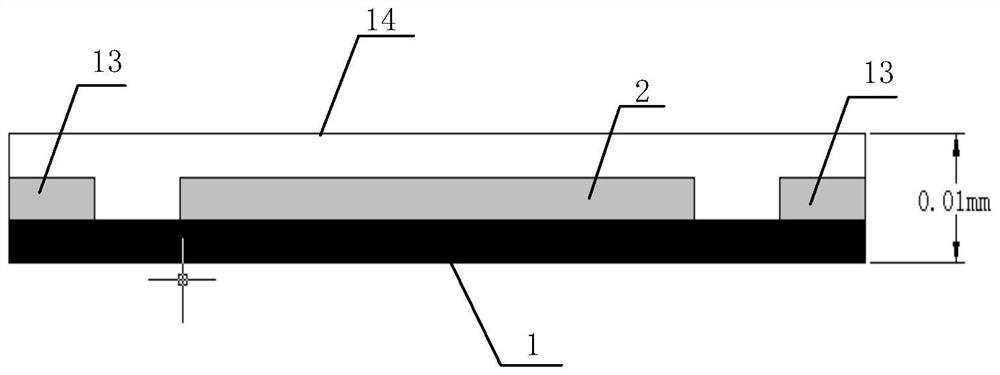

[0037] Step 1, polyimide is used as a substrate, and the thickness of the substrate is 50 μm. Ultrasonic cleaning with cleaning agent, then rinse with water and dry;

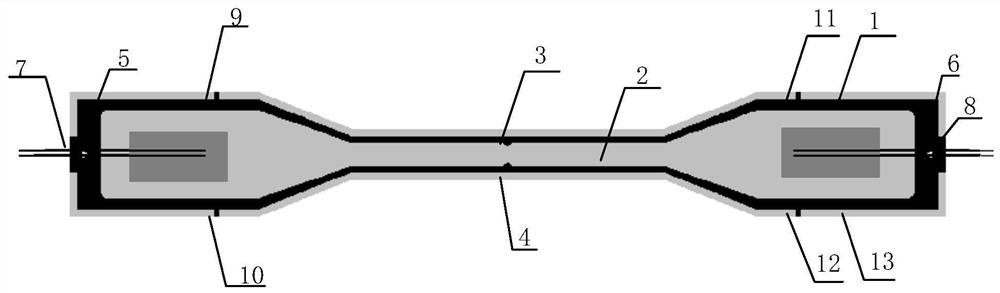

[0038] Step two, such as Figures 2 to 4 As shown, design a paddle-like structure 2 with left and right sides wide and narrow in the middle, and a first pull-off position positioning hole 3 and a second pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com