Manufacturing method of passive flexible temperature sensor based on micromachining process

A temperature sensor, passive flexible technology, applied in the field of microelectronics, can solve the problems such as the inability to quickly prepare flexible conductive lines in a large area, the difficulty of processing technology, and the limitation of circuit development, etc., to achieve rapid and accurate etching, low cost, and promotion of effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

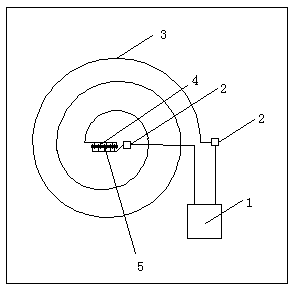

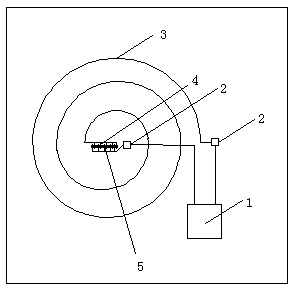

[0027] Embodiment 1: A kind of manufacturing method of passive flexible temperature sensor based on micromachining technology, etching processing: use microelectronics technology to print flexible coil and microelectrode on flexible substrate, and the material of flexible substrate is polyethylene terephthalate Ethylene glycol formate, the flexible substrate with flexible coils and micro-electrodes is a flexible substrate for one-time processing, and the width of the flexible coil on the flexible substrate for one-time processing is 5 μm; temperature-sensitive material alignment transfer: after sintering the temperature-sensitive material to The quasi-transfer to the micro-electrodes of the primary processing flexible substrate and overlap the micro-electrodes of the primary processing flexible substrate to obtain the secondary processing flexible substrate of the temperature-sensing module with temperature-sensitive characteristics; the IC chip is aligned and bonded; The IC ch...

Embodiment 2

[0028] Embodiment 2: A kind of manufacturing method of the passive flexible temperature sensor based on micromachining process, etching processing: plate a metal layer on the flexible substrate, the thickness of the metal layer is 30nm, and the material of the flexible substrate is polyimide Amine, when plating the metal layer, vacuum evaporation is used to etch the metal layer on the flexible substrate. The etching method is laser direct writing. After laser etching, flexible coils and micro electrodes are left, and the rest of the metal layer is removed by laser , after etching, the flexible coil and micro-electrode on the flexible substrate are obtained. The flexible substrate with the flexible coil and the micro-electrode is a flexible substrate for one-time processing, and the width of the flexible coil on the flexible substrate for one-time processing is 5 μm; the temperature sensitive material Alignment transfer: After sintering, the temperature sensitive material is ali...

Embodiment 3

[0029] Embodiment 3: A kind of manufacturing method of the passive flexible temperature sensor based on micromachining process, etching processing: plate a metal layer on the flexible substrate, the thickness of the metal layer is 1 μm, and the material of the flexible substrate is polydimethylformaldehyde Silicone-based siloxane, sputtering coating is used when coating the metal layer, and the metal layer on the flexible substrate is etched. The etching method is a combination of laser direct writing and photolithography. The photoresist is positive photolithography during photolithography. After the positive photoresist is spin-coated on the surface of the metal layer, the photolithographic exposure is carried out. During the photolithographic exposure, it is placed under a mask with flexible coils and micro-electrode patterns. The pattern of the mask is opaque and the non-pattern is transparent. After photolithography exposure, it is developed with a photolithography develop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com