Preparation method of high-energy-storage battery diaphragm material

A battery diaphragm and high energy storage technology, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of diaphragm performance degradation, combustible fire disasters, damage, etc., and achieve improved mechanical strength and thermal stability. Mechanical strength and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

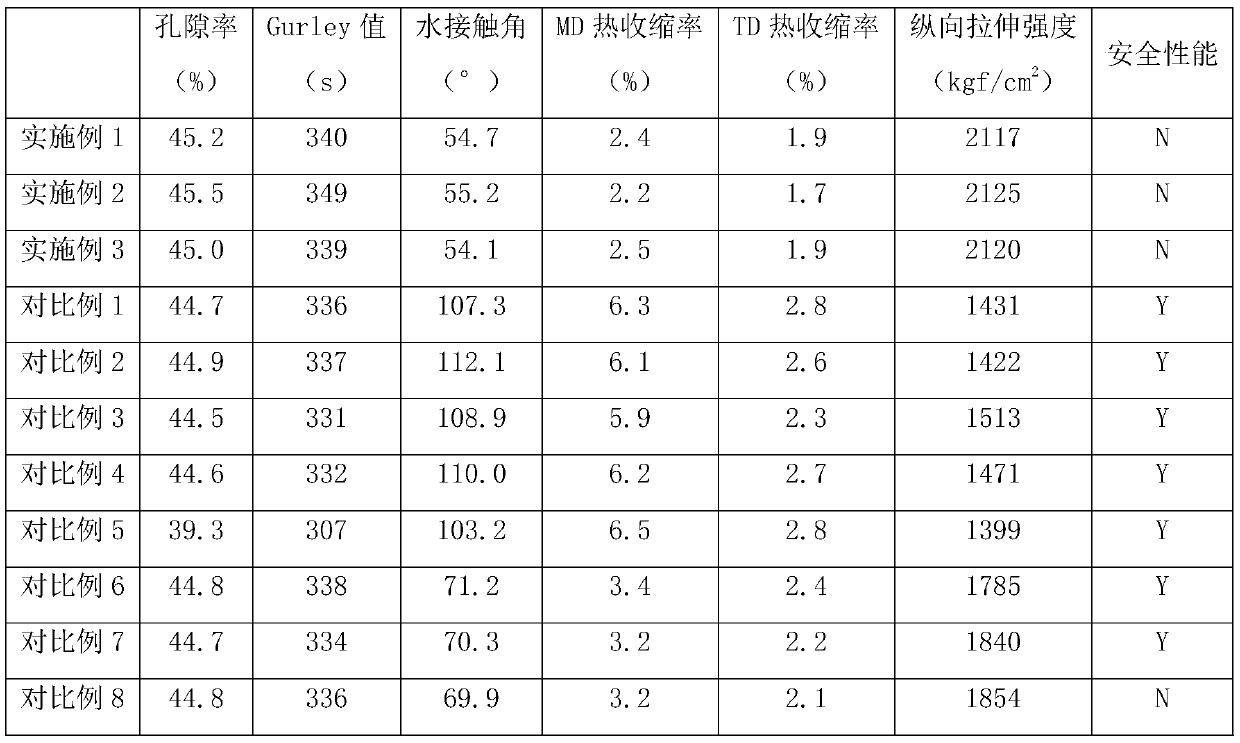

Examples

Embodiment 1

[0027] A preparation method of high energy storage battery diaphragm material, comprising the following steps:

[0028] S1. Add LDPE and xylene to 170g LDPE per liter of xylene into the reaction vessel, heat and stir to dissolve LDPE completely, when the temperature rises to 110°C, add DCP at 0.05% of the mass of LDPE, DCP is pre-dissolved with xylene to prepare a solution After adding DCP, keep it warm for 4 hours and then stop the reaction. When the temperature drops to room temperature, add ethanol to the system in the amount of 1L of ethanol per 200g LDPE, stir for 30 minutes, and the product precipitates, then suction filter and wash with acetone for 3-5 times, at 70°C Dried to constant weight to obtain maleic anhydride grafted polyethylene product;

[0029] S2, the maleic anhydride grafted polyethylene is completely dissolved in butyl acetate, the butyl acetate of every 100g maleic anhydride grafted polyethylene needs to be 0.8L, obtains the maleic anhydride grafted poly...

Embodiment 2

[0036] A preparation method of high energy storage battery diaphragm material, comprising the following steps:

[0037] S1. Add LDPE and xylene to 180g LDPE per liter of xylene into the reaction vessel, heat and stir to dissolve LDPE completely, when the temperature rises to 115°C, add DCP at 0.055% of the mass of LDPE, DCP is prepared by dissolving xylene in advance Solution, after adding DCP, keep it warm for 4.5h and then stop the reaction. When the temperature drops to room temperature, add ethanol to the system according to the amount of 1L of ethanol per 200g LDPE, stir for 45min, the product precipitates out, suction filter and wash with acetone for 3-5 times, Dry at 75°C to constant weight to obtain maleic anhydride grafted polyethylene product;

[0038] S2, the maleic anhydride grafted polyethylene is completely dissolved in butyl acetate, the butyl acetate of every 100g maleic anhydride grafted polyethylene needs to be 1.2L, obtains the maleic anhydride grafted polye...

Embodiment 3

[0045] A preparation method of high energy storage battery diaphragm material, comprising the following steps:

[0046] S1. Add LDPE and xylene to 190g LDPE per liter of xylene into the reaction vessel, heat and stir to dissolve LDPE completely, when the temperature rises to 120°C, add DCP according to 0.06% of the mass of LDPE, DCP is pre-dissolved with xylene to prepare a solution After adding DCP, keep it warm for 5 hours and then stop the reaction. When the temperature drops to room temperature, add ethanol to the system according to the amount of 1L of ethanol per 200g of LDPE, stir for 60 minutes, the product precipitates, then suction filter and wash with acetone 3-5 times, 80 ℃ Dried to constant weight to obtain maleic anhydride grafted polyethylene product;

[0047] S2, the maleic anhydride grafted polyethylene is completely dissolved in butyl acetate, and the butyl acetate of every 100g maleic anhydride grafted polyethylene needs to be 1.5L to obtain the maleic anhyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com