A kind of high-nickel ternary material in-situ coating method

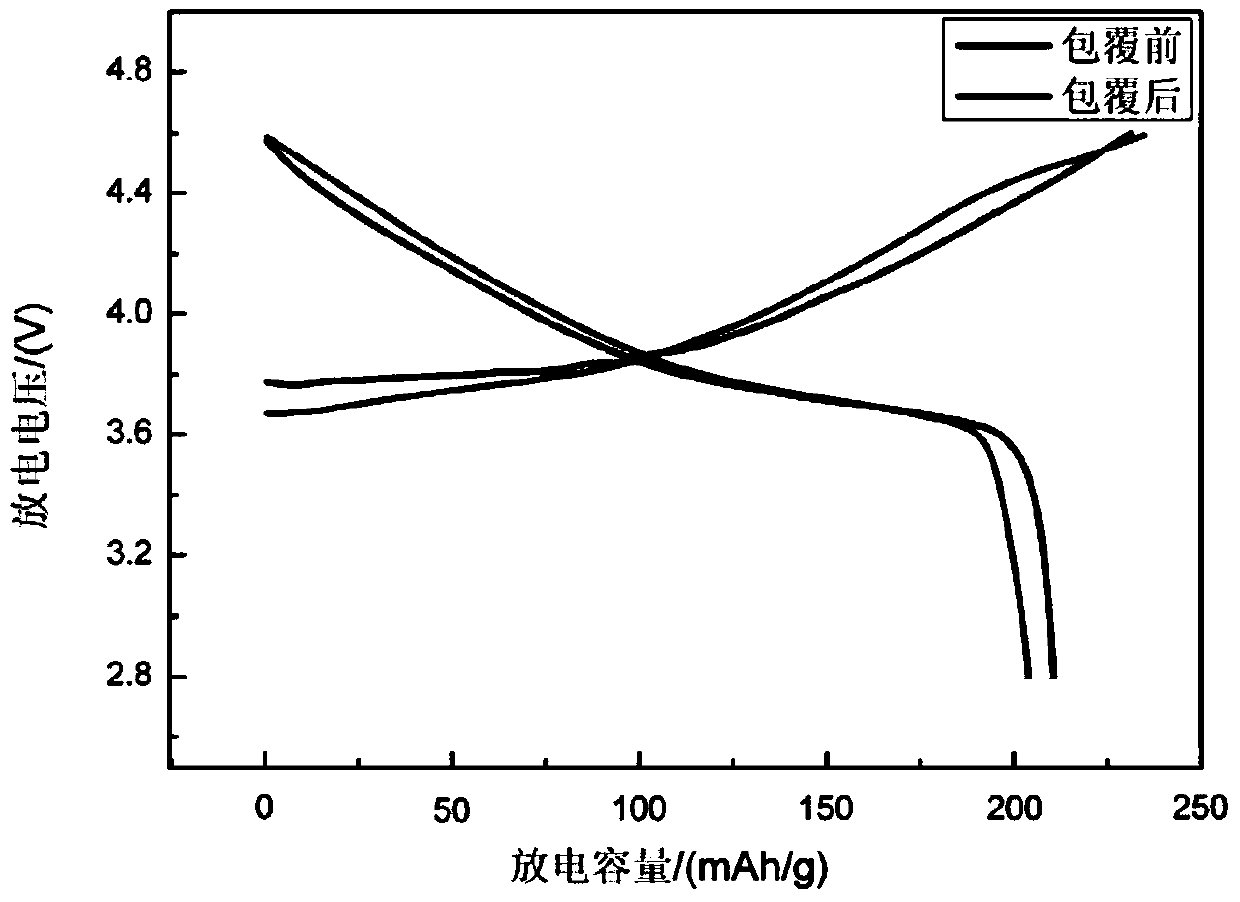

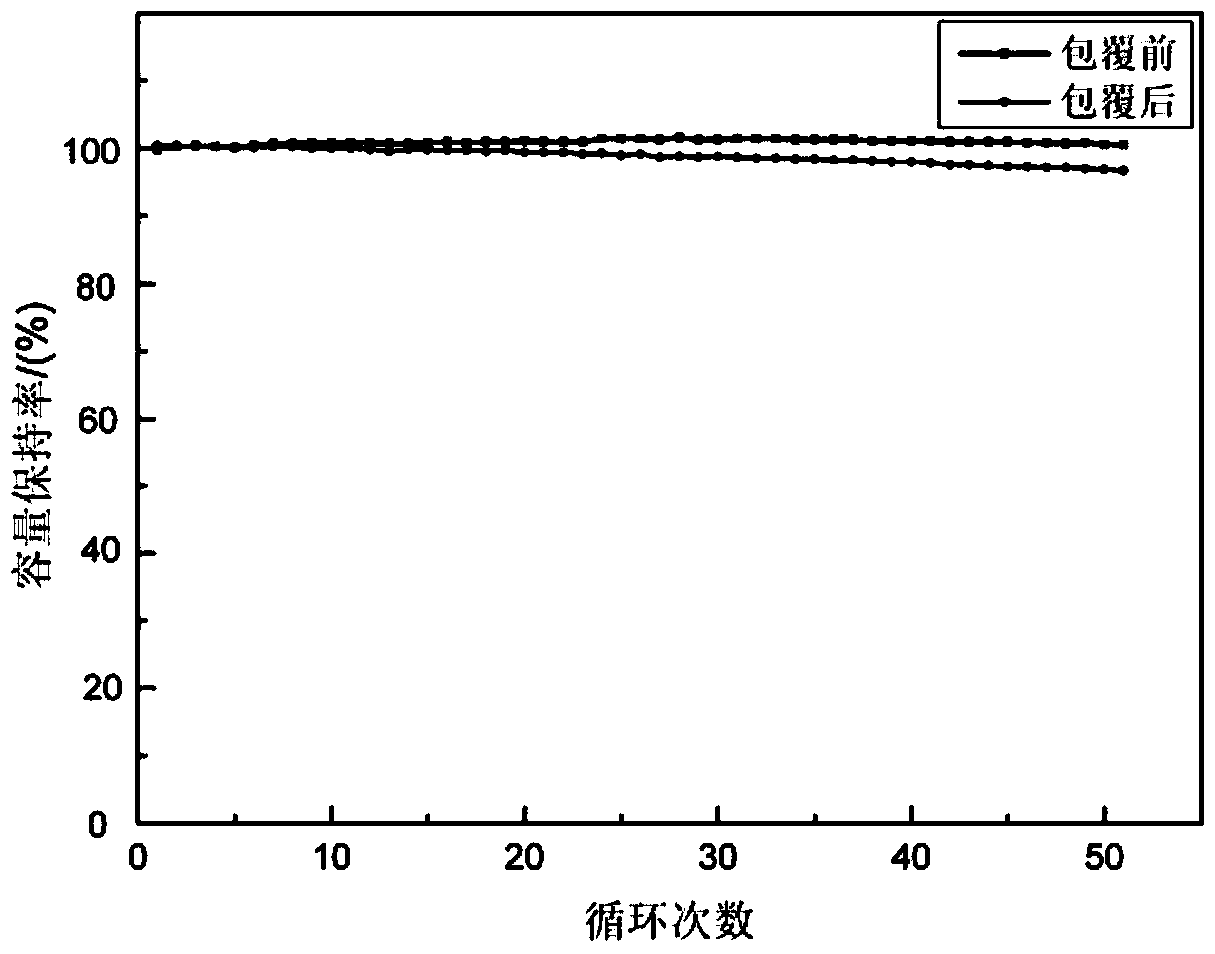

A high-nickel ternary material and in-situ coating technology, applied to electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of increased battery impedance, low conductivity, poor cycle performance, etc., to achieve inhibition of formation, Effect of suppressing reduction in capacity and rate performance and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-nickel ternary material in-situ coating method, comprising the following process steps:

[0028] First prepare 1L of dilute sulfuric acid solution with a volume fraction of 2%, add 1.2Kg LiNi 0.5 co 0。2 mn 0.3 o 2 The ternary material was stirred continuously, treated at room temperature for 40 minutes, then filtered, and washed with distilled water until the pH value reached above 6, and then dried in a nitrogen oven at 120°C for 5 hours; the dried powder was mixed according to the mass ratio 1: Add 4.8g NaOH at 0.4%, then add 1L of distilled water, stir and mix evenly, and send it to a spray dryer for spray drying. The amount of material is 0.5L / h; after the spray drying is completed, it is sent to the sintering furnace and sintered in the air atmosphere for 3 hours at a sintering temperature of 750°C. After the sintering is completed, the product is obtained by sieving.

Embodiment 2

[0030] A high-nickel ternary material in-situ coating method, comprising the following process steps:

[0031] First prepare 1L of dilute nitric acid solution with a volume fraction of 3%, add 1.2Kg LiNi 0.5 co 0.2 mn 0.3 o 2 The ternary material was stirred continuously, treated at room temperature for 30 minutes, then filtered, and washed with distilled water until the pH value reached above 6, and then dried in a nitrogen oven at 120°C for 6 hours; the dried powder was mixed according to the mass ratio 1: Add 6g NaOH at 0.5%, then add 1L of distilled water, stir and mix evenly, then send it to the spray dryer for spray drying, the heating air pressure is 0.5MPa, the inlet temperature is 300°C, the outlet temperature is 100°C, the feed The amount is 0.7L / h; after the spray drying is completed, it is sent to a sintering furnace, and sintered in an air atmosphere for 5 hours at a sintering temperature of 780°C. After the sintering is completed, it is sieved to obtain the pr...

Embodiment 3

[0033] A high-nickel ternary material in-situ coating method, comprising the following process steps:

[0034] First prepare 1L of dilute phosphoric acid solution with a volume fraction of 4%, add 1.2Kg LiNi 0.6 co 0。2 mn 0.2 o 2The ternary material was stirred continuously, treated at room temperature for 20 minutes, then filtered and washed with distilled water until the pH value reached above 6, and then dried in a nitrogen oven at 130°C for 7 hours; the dried powder was mixed according to the mass ratio 1: Add 4.8g NaOH at 0.4%, then add 1L of distilled water, stir and mix evenly, and send it to a spray dryer for spray drying. The amount of material is 0.5L / h; after the spray drying is completed, it is sent to the sintering furnace and sintered in the air atmosphere for 3 hours at a sintering temperature of 850°C. After the sintering is completed, the product is obtained by sieving.

[0035] This embodiment has the advantages of simple process and convenient operation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com