Formation method of power lithium ion battery in high-temperature environment

A technology of lithium-ion batteries and formation methods, which is applied in the field of formation of power lithium-ion batteries used in high-temperature environments, and can solve problems such as affecting the cycle life of power lithium-ion batteries, difficult to cool the temperature of the battery core, and increasing the production cost of battery packs , to achieve good temperature resistance, improve high temperature stability, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

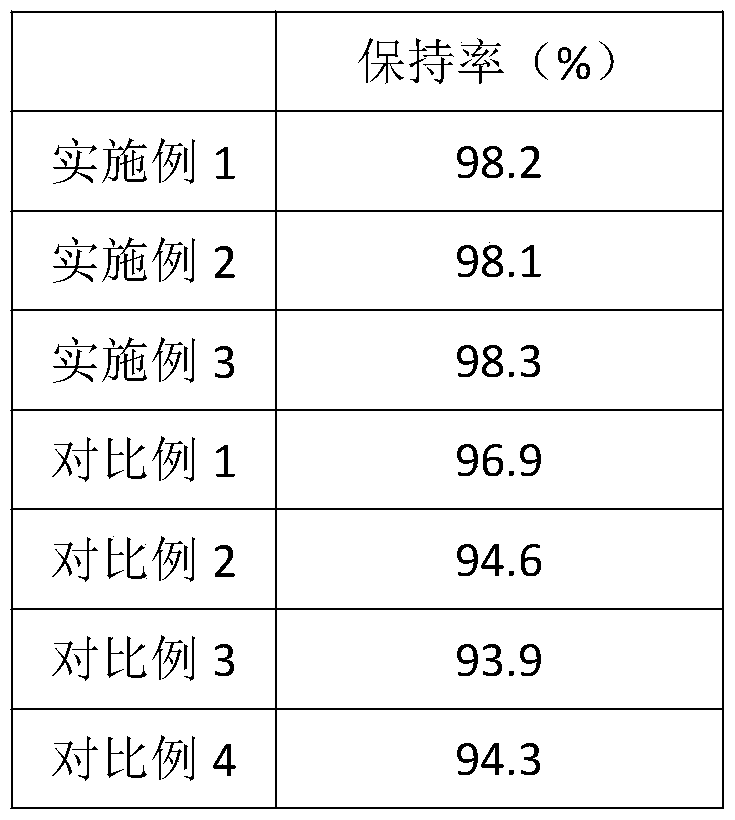

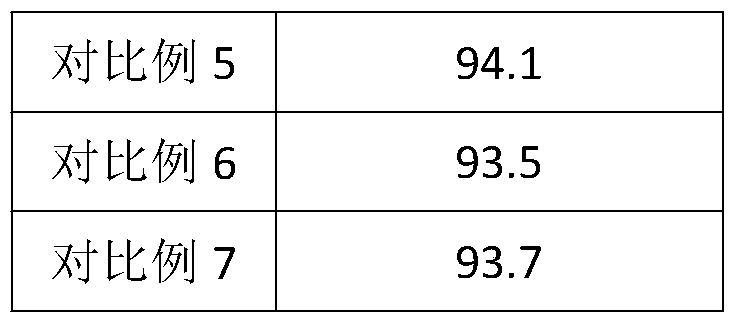

Embodiment 1

[0029] The electrolyte is 1M lithium hexafluorophosphate, and the solvent is composed of ethylene carbonate and propylene carbonate with a volume ratio of 2:1; the volume percentage of 1,3-propene sultone, vinylene carbonate and vinyl sulfate in the additive The contents are respectively 1%, 0.6%, 1.8%.

[0030] 1) Charge to a first predetermined voltage with a constant current of 0.02C, and the first predetermined voltage is 3.35V;

[0031] 2) 4 cycles of 0.05C constant current charging and discharging between the first predetermined voltage and the discharge cut-off voltage, the discharge cut-off voltage being 2.75V;

[0032] 3) Constant voltage charging with the first predetermined voltage until the charging current is lower than 0.01C;

[0033] 4) Constantly charge with a current of 0.02C to a second predetermined voltage, and the second predetermined voltage is 4.05V

[0034] 5) Constant voltage charging with the second predetermined voltage until the charging current i...

Embodiment 2

[0040] The electrolyte is 1M lithium hexafluorophosphate, and the solvent is composed of ethylene carbonate and propylene carbonate with a volume ratio of 1:2; the volume percentage of 1,3-propene sultone, vinylene carbonate and vinyl sulfate in the additive The contents are respectively 1.5%, 0.8%, 2.0%.

[0041] 1) Charging to a first predetermined voltage with a constant current of 0.05C, and the first predetermined voltage is 3.40V;

[0042] 2) 4 cycles of 0.05C constant current charging and discharging between the first predetermined voltage and the discharge cut-off voltage, the discharge cut-off voltage being 2.75V;

[0043] 3) Constant voltage charging with the first predetermined voltage until the charging current is lower than 0.01C;

[0044] 4) Charging with a constant current of 0.05C to a second predetermined voltage, the second predetermined voltage is 4.10V

[0045] 5) Constant voltage charging with the second predetermined voltage until the charging current i...

Embodiment 3

[0051] The electrolyte is 1M lithium hexafluorophosphate, and the solvent is composed of ethylene carbonate and propylene carbonate with a volume ratio of 1:1; the volume percentage of 1,3-propene sultone, vinylene carbonate and vinyl sulfate in the additive The contents are respectively 1.2%, 0.7%, 1.9%.

[0052] 1) Charging to a first predetermined voltage with a constant current of 0.03C, and the first predetermined voltage is 3.40V;

[0053] 2) 4 cycles of 0.05C constant current charging and discharging between the first predetermined voltage and the discharge cut-off voltage, the discharge cut-off voltage being 2.75V;

[0054] 3) Constant voltage charging with the first predetermined voltage until the charging current is lower than 0.01C;

[0055] 4) Constantly charge with a current of 0.03C to a second predetermined voltage, and the second predetermined voltage is 4.10V

[0056] 5) Constant voltage charging with the second predetermined voltage until the charging curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com