A method for treating propylene oxide high-COD alkaline wastewater by biochemical process

A propylene oxide and waste water technology, which is applied in aerobic process treatment, aerobic and anaerobic process treatment, anaerobic digestion treatment and other directions, can solve the problems of innocence, resource utilization, and heavy environmental burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

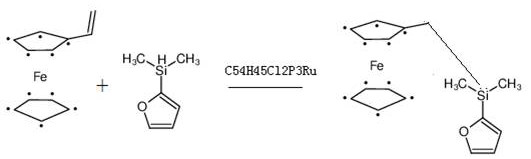

Method used

Image

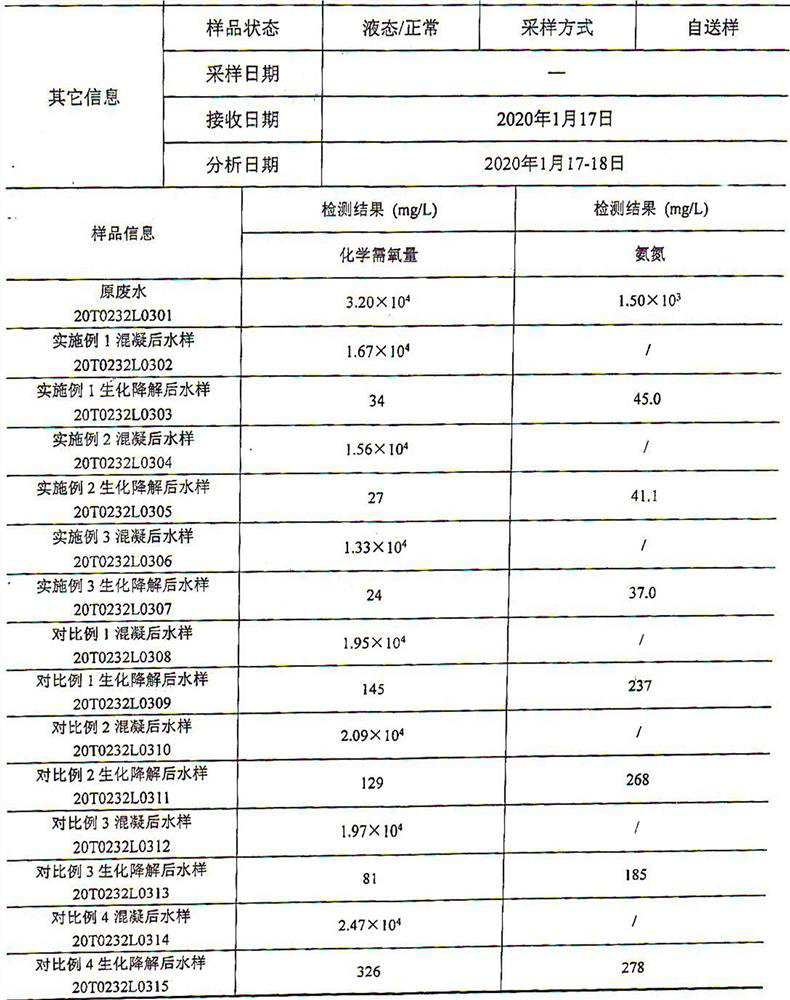

Examples

Embodiment 1

[0030] A method for biochemical processing of propylene oxide high COD alkaline wastewater, its technical scheme is as follows:

[0031] Step 1, acidification treatment, skimming off the slick oil on the surface of the wastewater, then adding sulfuric acid to adjust the pH value of the wastewater to 2, stirring evenly and then standing still, oily organic matter will appear on the surface of the wastewater, and the oil layer is skimmed to obtain the crude phenolic component in the wastewater ;

[0032] Step 2, air flotation treatment, the acidified wastewater is subjected to air flotation treatment, and the oily organic matter precipitated from the wastewater is further separated;

[0033] Step 3, coagulation and precipitation, adding 0.5mol / L sodium hydroxide solution to adjust the pH value to 5, and then adding 0.1kg / m 3 The polyacrylamide is stirred and mixed uniformly and enters the sedimentation tank to remove coagulated organic matter; it is characterized in that the fl...

Embodiment 2

[0044] A method for biochemical processing of propylene oxide high COD alkaline wastewater, its technical scheme is as follows:

[0045] Step 1, acidification treatment, skimming the slick oil on the surface of the wastewater, then adding sulfuric acid to adjust the pH value of the wastewater to 3, stirring evenly and then standing still, oily organic matter will appear on the surface of the wastewater, and the oil layer is skimmed to obtain the crude phenolic component in the wastewater ;

[0046] Step 2, air flotation treatment, the acidified wastewater is subjected to air flotation treatment, and the oily organic matter precipitated from the wastewater is further separated;

[0047] Step 3, coagulation and precipitation, add 2.5mol / L sodium hydroxide solution to adjust the pH value to 7, then add 0.5kg / m 3 The polyacrylamide is stirred and mixed uniformly and enters the sedimentation tank to remove coagulated organic matter; it is characterized in that the flocculant is a ...

Embodiment 3

[0057] A method for biochemical processing of propylene oxide high COD alkaline wastewater, its technical scheme is as follows:

[0058] Step 1, acidification treatment, skimming the slick oil on the surface of the wastewater, then adding sulfuric acid to adjust the pH value of the wastewater to 4, stirring evenly and then standing still, oily organic matter will appear on the surface of the wastewater, and the oil layer is skimmed to obtain the crude phenolic component in the wastewater ;

[0059] Step 2, air flotation treatment, the acidified wastewater is subjected to air flotation treatment, and the oily organic matter precipitated from the wastewater is further separated;

[0060] Step 3, coagulation and precipitation, adding 5mol / L sodium hydroxide solution to adjust the pH value to 8, and then adding 1kg / m 3 The polyacrylamide is stirred and mixed uniformly and enters the sedimentation tank to remove coagulated organic matter; it is characterized in that the flocculant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com