Welding slag cleaning method

A technology of welding slag and cleaning agent, which is applied in the field of cleaning agent, can solve the problem of low cleaning agent use efficiency, and achieve the effect of easy storage and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

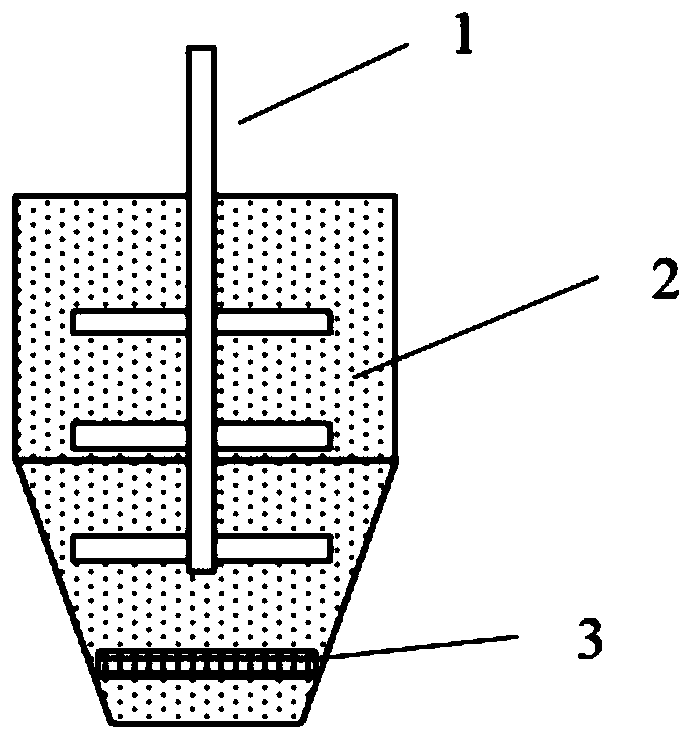

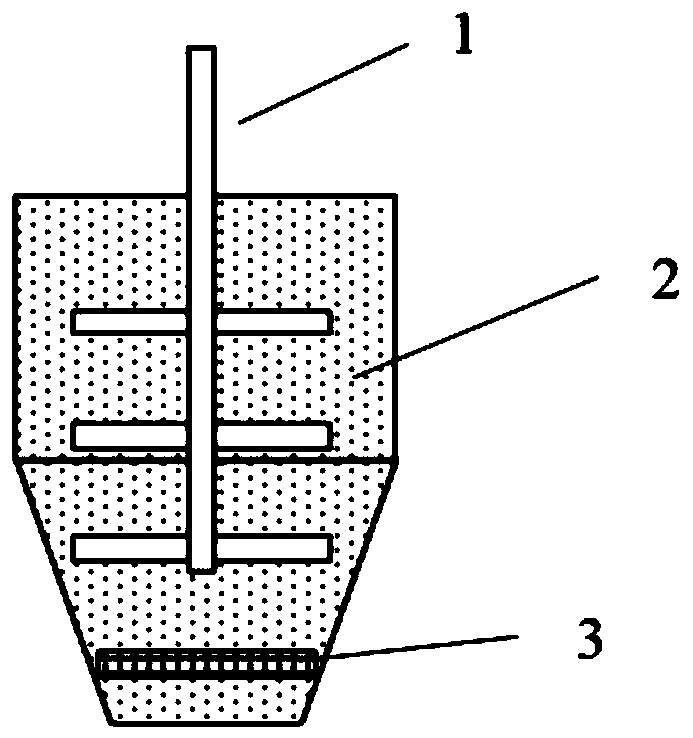

Image

Examples

Embodiment 1

[0027] A new type of welding slag cleaning agent, select 40 parts of limonene, 30 parts of methanol, 30 parts of high-boiling range petroleum ether, do not add emulsifier and penetrating agent, then add limonene, methanol, and high-boiling range petroleum ether into the reaction vessel and mix well. .

Embodiment 2

[0029] A new type of welding slag cleaning agent, select 60 parts of limonene, 20 parts of ethanol, 20 parts of high-boiling range petroleum ether, do not add emulsifier and penetrating agent, then add limonene, methanol, and high-boiling range petroleum ether into the reaction vessel and mix well. .

Embodiment 3

[0031] A new type of welding slag cleaning agent, select 50 parts of limonene, 26 parts of isopropanol and ethanol 1:1 mixed solvent, 22 parts of high boiling range petroleum ether, 1 part of castor oil polyoxyethylene ether, and 1 part of penetrating agent. Wherein, the penetrating agent is a mixture of 1,4-cyclohexanediol dimethyl ether and N-benzylamine phenylenediamine, and the weight ratio of 1,4-cyclohexanediol dimethyl ether and N-benzylamine phenylenediamine is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com