Pressure infiltration preparation device and preparation method for aluminum matrix composite

A technology of an aluminum matrix composite material and a preparation device, which is applied in the field of metal matrix composite material preparation, can solve the problem that a single furnace tube vacuum resistance furnace cannot realize the stable preparation of multiple composite materials, cannot achieve the same simultaneous preparation of reinforcement, and reduces the preparation efficiency of composite materials. and other problems to achieve the effect of reducing hole defects, improving performance and quality, and improving vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

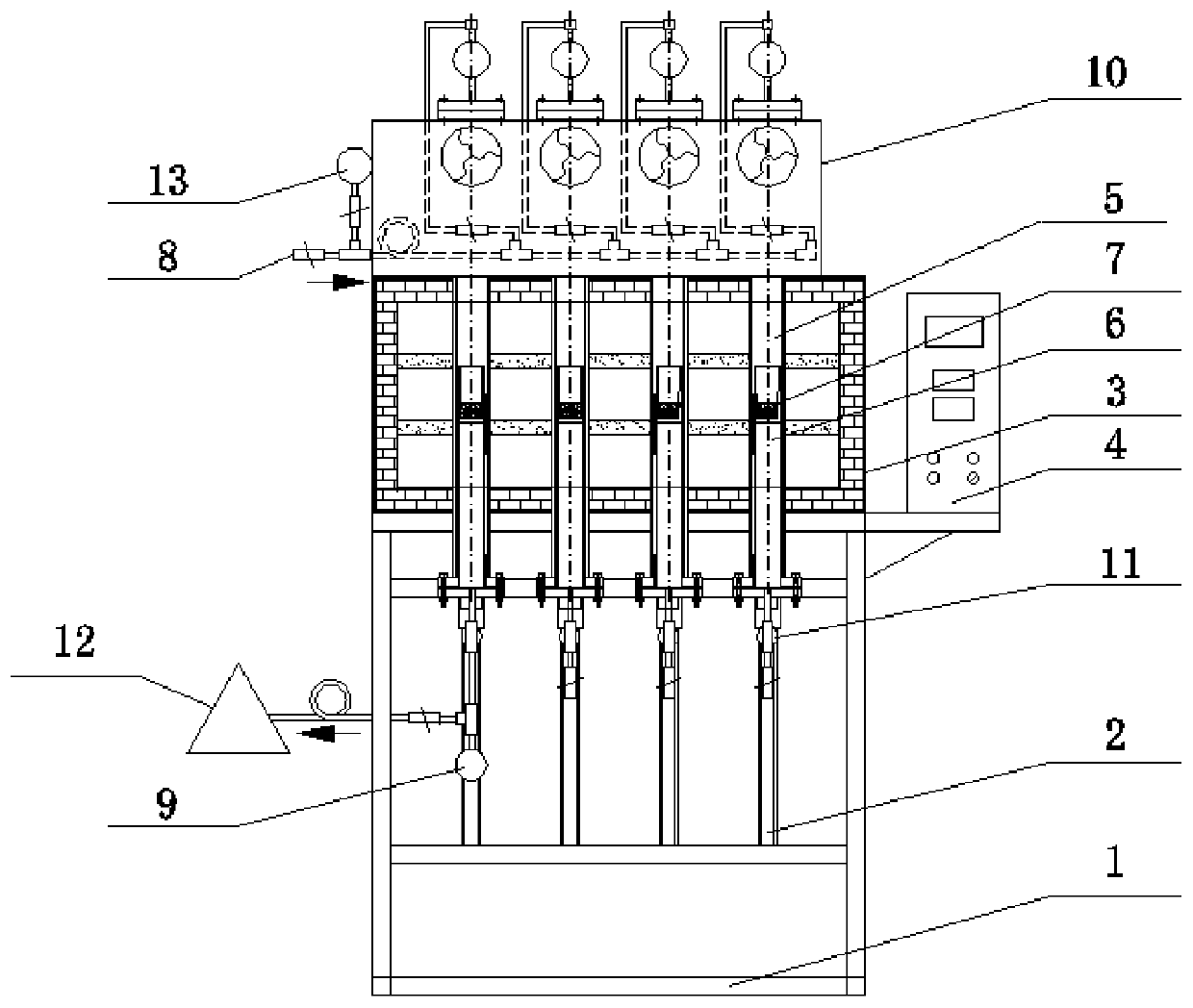

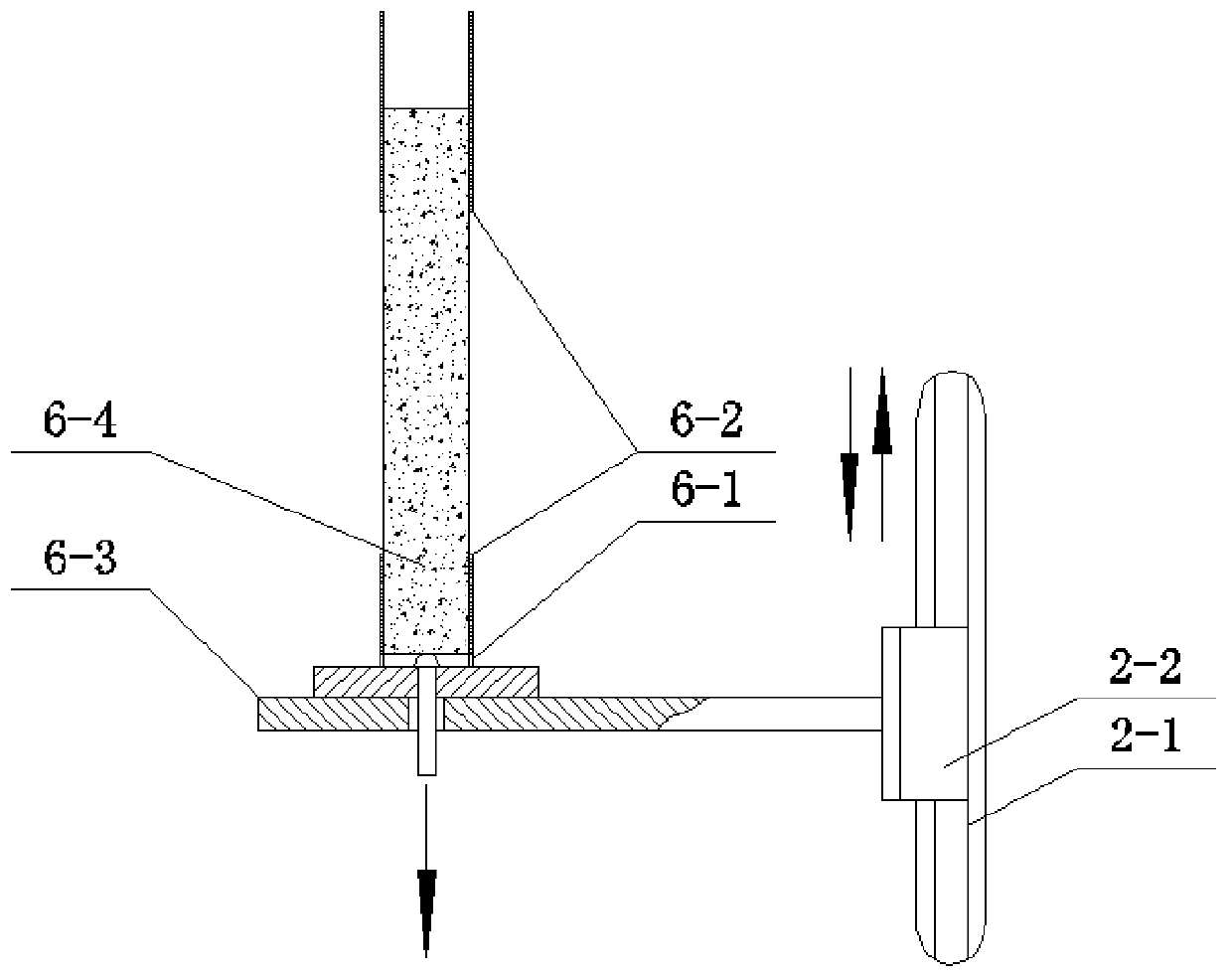

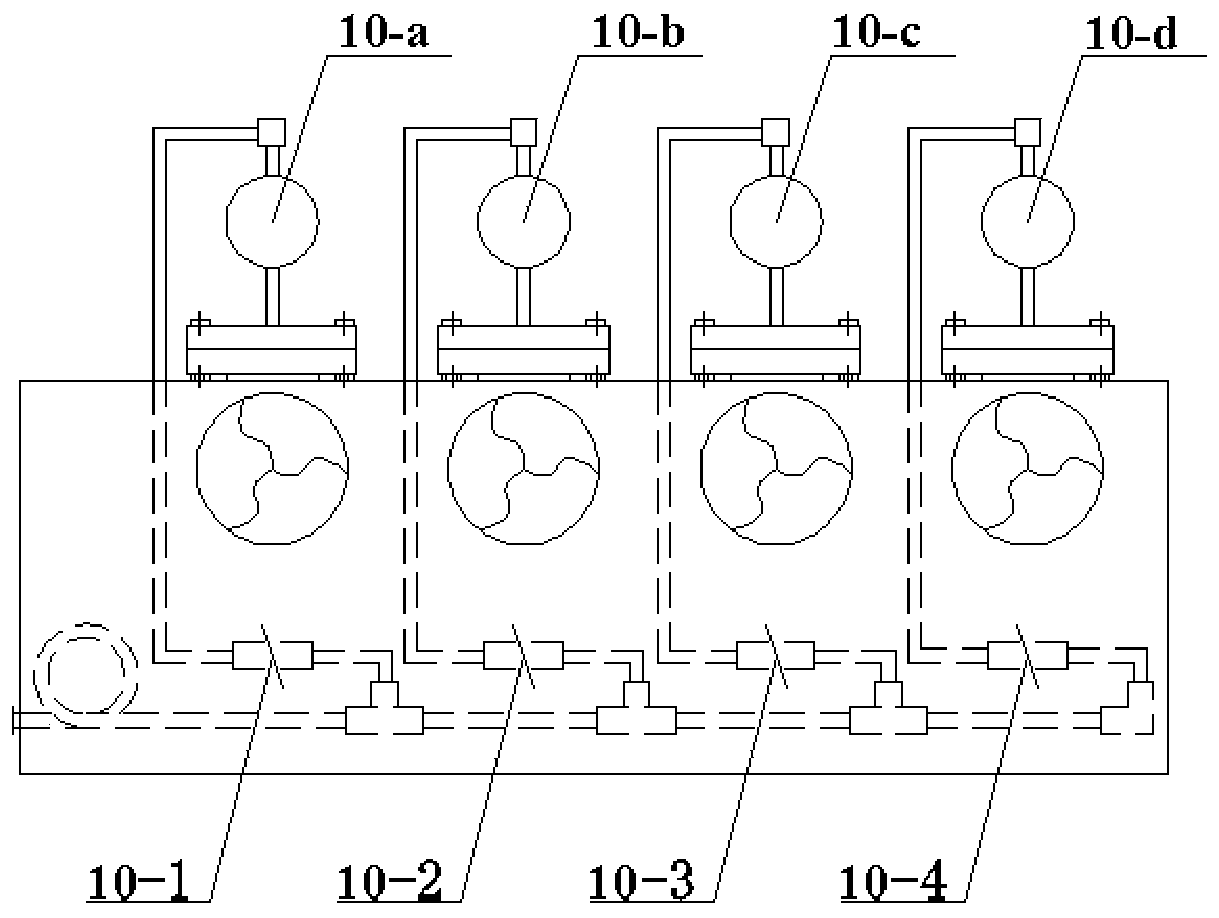

[0036] A kind of aluminum matrix composite material pressure impregnation preparation device of this embodiment, its overall structure schematic diagram is as follows figure 1 shown. It includes a frame 1, four lifting mechanisms 2, a resistance furnace 3, an infiltration pressure control system, a vacuum control system and an electric control cabinet 4. Each lifting mechanism can be lifted into the resistance furnace 3 through an independent furnace tube 5. A crucible support 6 is arranged at the upper end of the lifting mechanism, and a stainless steel crucible 7 is placed at the upper end of the crucible support 6; the structural diagram of the lifting mechanism is as follows figure 2 As shown, the lifting mechanism realizes sliding connection with the guide rail 2-1 through the slider 2-2, the crucible support includes a support rod 6-3 and a sleeve 6-2, the support rod 6-3 is connected to the slider 2-2, and the sleeve is built in Insert the refractory brick 6-4, place ...

Embodiment 2

[0038] Adopt the device of embodiment 1 to prepare SiC p Reinforced aluminum-based composite materials, including the following steps and process conditions:

[0039] (1) SiC with a particle size of 90 μm p Add industrial starch and silica sol and stir evenly, SiC p , industrial starch and silica sol volume fractions were 70%, 20% and 10%. SiC with a size of Φ30mm×80mm was produced by compression molding p Prefabricated body, sintered at 900°C to obtain SiC p Preform;

[0040] (2) Put SiC in four stainless steel crucibles p The prefabricated body and AlSi12 alloy, the stainless steel crucible is lifted into the inner furnace tube of the resistance furnace through the lifting mechanism, and the furnace tube is sealed;

[0041] (3) Turn on the vacuum pump to extract the air inside the furnace tube of the resistance furnace, so that the vacuum degree in the furnace tube reaches 70Pa;

[0042] (4) Control the temperature of the resistance furnace to 750°C through the electr...

Embodiment 3

[0047]Adopt the device of embodiment 1 to prepare SiC p and B 4 C p Reinforced aluminum-based composite materials, including the following steps and process conditions:

[0048] (1) SiC with a particle size of 50 μm, respectively p and B 4 C p Add industrial starch and silica sol and stir evenly, the volume fractions of reinforcing phase, industrial starch and silica sol are 70%, 20% and 10% respectively. SiC with a size of Φ30mm×80mm was produced by compression molding p and B 4 C p Prefabricated body, sintered at 900°C to obtain SiC p and B 4 C p Preform;

[0049] (2) Put SiC in No. 1 and No. 2 stainless steel crucibles p Preform and A356 alloy, put B in No. 3 and No. 4 stainless steel crucibles 4 C p For the prefabricated body and the A356 alloy, four stainless steel crucibles are lifted into the corresponding furnace tubes of the resistance furnace through the lifting mechanism, and the furnace tubes are sealed;

[0050] (3) Turn on the vacuum pump to extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com