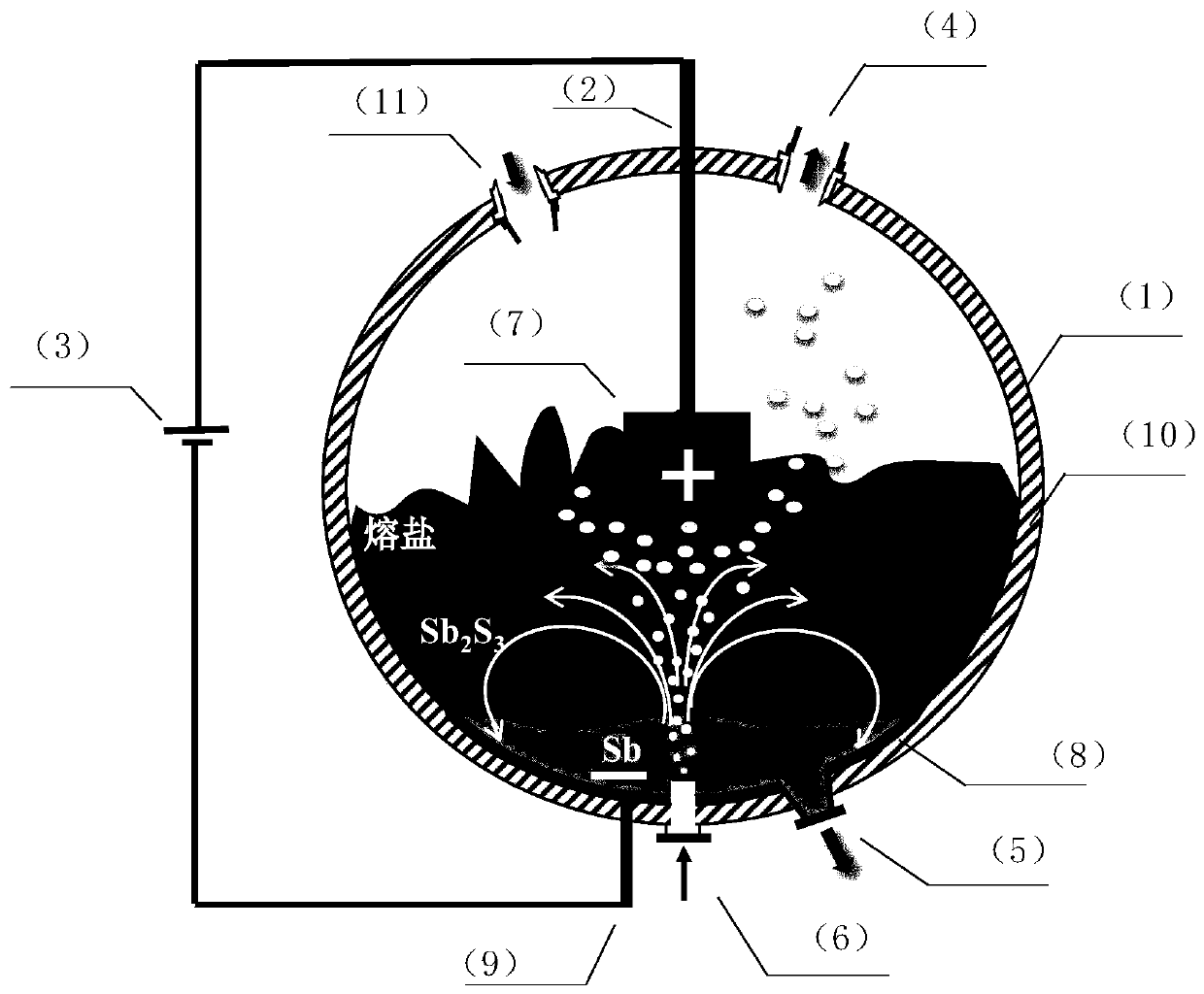

Method and device for molten salt electrolysis of materials containing antimony sulfide

A technology of molten salt electrolysis and antimony sulfide, which is applied in the direction of electrolysis components and electrolysis processes, can solve the problems of high energy consumption and complex equipment, and achieve the effects of shortening the reaction time, promoting condensation and sedimentation, and strengthening the mass transfer of molten salt ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The chemical composition of antimony sulfide concentrate A is (%): Sb 51.5, Fe 2.3, S 16.6, As 0.39, Pb 0.42, SiO 2 12.1. Take by weighing 600g of the antimony sulfide concentrate, 120g Na 2 S, 474.6g NaCl and 605.4g KCl. After mixing evenly, spread it on the bottom of the bottom blowing molten salt electrolysis device. Adjust the height of the anode guide rod so that the graphite anode is inserted into the mixed material, and the distance between the cathode and the anode is 4cm. Turn on the power supply of the external resistance heating layer and raise the temperature to 880°C. Blow nitrogen gas with a preheating temperature of 880°C and a pressure of 0.2 MPa from the gas nozzle at the bottom of the electrolytic cell to stir the molten salt, turn on the DC electrolytic power supply, set the cell voltage to a constant voltage of 2.2 V, and finish the reaction after 60 minutes of reaction. After the antimony was discharged from the antimony discharge port, 306g of...

Embodiment 2

[0047] The chemical composition of antimony sulfide concentrate B is (%): Sb 32.1, Fe 16.4, S 30.2, As 1.5, SiO 2 13.5, Pb1.2. Weigh 1200g of the antimony sulfide concentrate B, 600g K 2 S, 1054.8g NaCl and 1345.2g KCl and mix well. After that, the mixed material is spread on the bottom of the bottom-blown molten salt electrolysis device. Adjust the height of the anode guide rod so that the graphite anode is inserted into the upper mixed material, and the distance between the cathode and the anode is 10cm. Turn on the power supply of the external resistance heating layer and raise the temperature to 920°C. Blow argon gas with a preheating temperature of 920°C and a pressure of 0.3 MPa from the gas nozzle at the bottom of the electrolytic cell to stir the molten salt, turn on the DC electrolytic power supply, set the cell voltage to a constant voltage of 2.3V, and finish the reaction after 90 minutes of reaction. After the antimony was discharged from the antimony discharge...

Embodiment 3

[0049] Carry out low-temperature molten salt electrolysis of antimony concentrate with the same raw material and test parameters in the above-mentioned embodiment 1, expand the experimental scale by 10 times, take by weighing 6000g of this antimony sulfide concentrate, 1200g Na 2 S, 4746g NaCl and 6054g KCl. However, parameters such as temperature, pressure, and voltage were not changed. After 120 minutes of reaction, the reaction was terminated. After the antimony was discharged from the antimony discharge port and cooled, 3042g of monolithic antimony was directly collected, the grade of antimony was 98.1%, and the direct antimony recovery rate was 96.6%. The purity of 90.5% S906g was collected in the flue gas collection bag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com