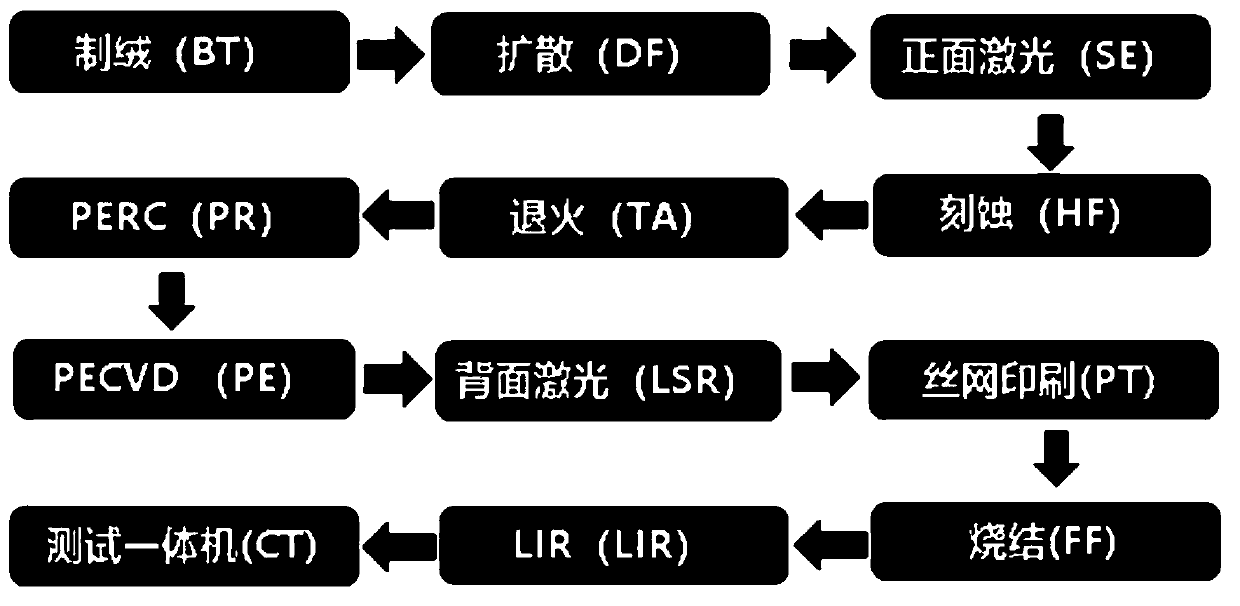

Preparation method of selective emitter battery

An emitter and selective technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of large damage area of cells and insufficient uniformity of laser spot, etc., achieve low equipment cost, improve cell conversion efficiency, reduce The effect of damage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

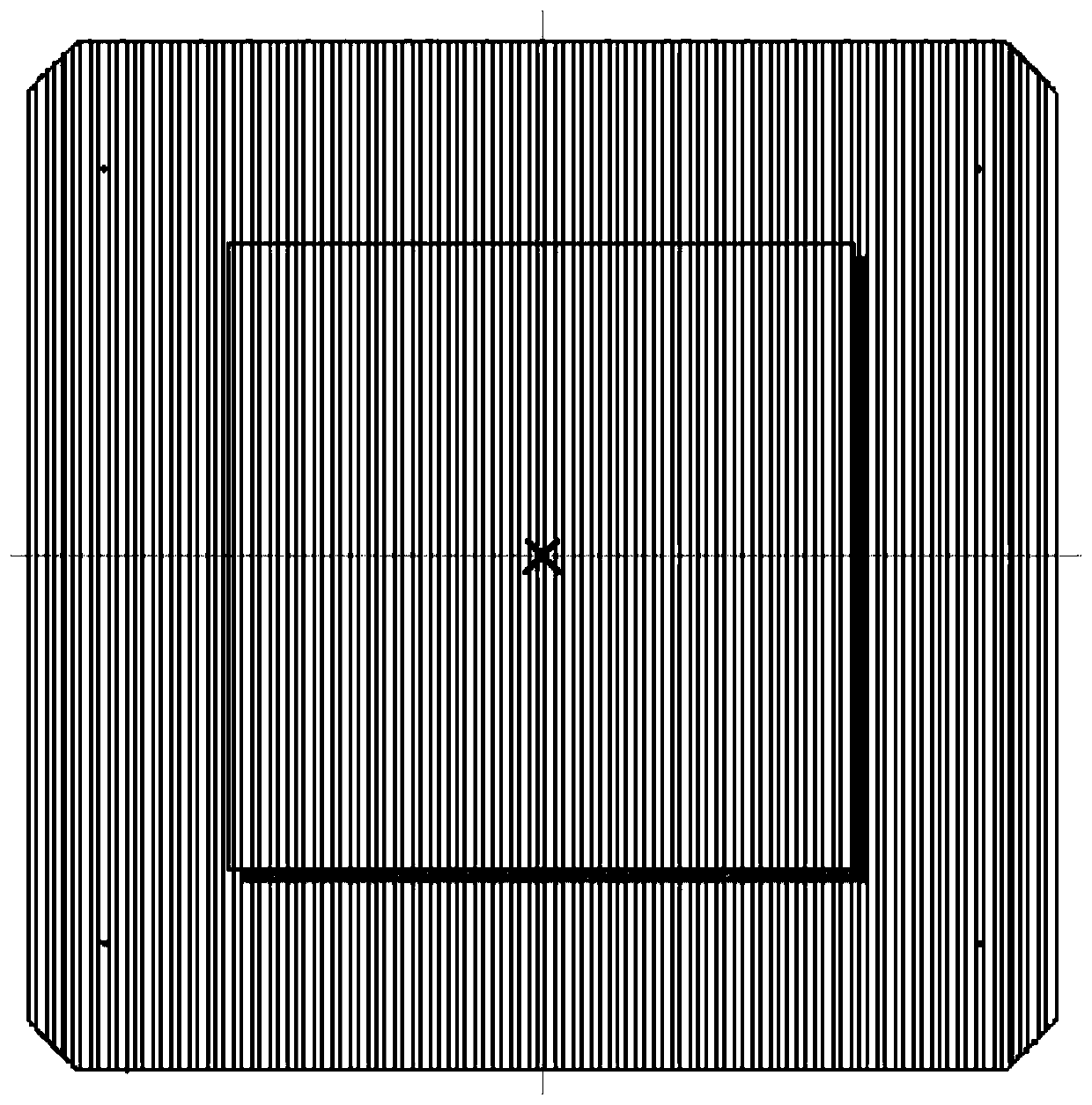

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand and implement the technical solutions of the present invention.

[0028] The mechanism of the embodiment of the present invention to improve the battery conversion effect is as follows:

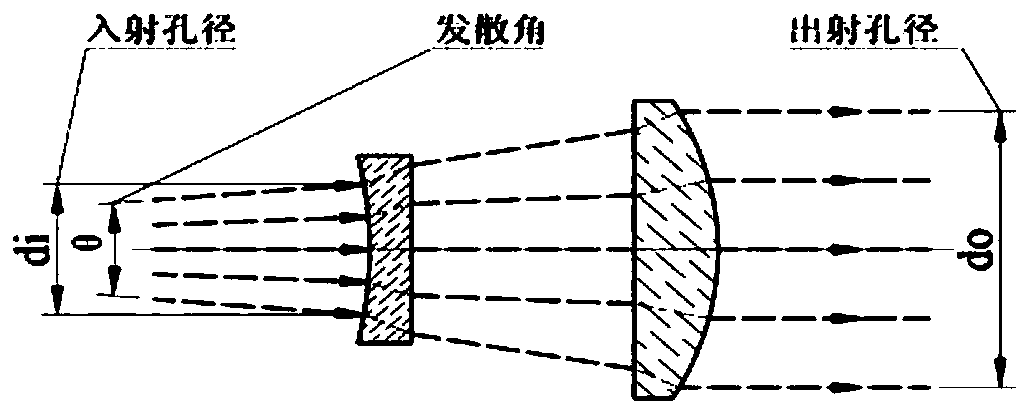

[0029] The particles are in the ground state at room temperature, and energy needs to be injected by the pump source to pump a large amount of particles to the excited state, and the inversion of the number of particles in the upper and lower energy levels creates the necessary conditions for the generation of laser light. The population inversion is only a necessary condition for generating stimulated radiation, and it cannot generate laser light. Only by placing the active material in the optical resonant cavity and selecting the frequency and direction of light can continuous light amplification and laser oscillation output be obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com