Carrier plate for growing thin film on substrate, growth device and growth method

A technology for carrying discs and substrates, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of inconvenient replacement, fragile, and difficult to find stable and adhesive adhesives, etc. The effect of short replacement cycle, high use cost and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

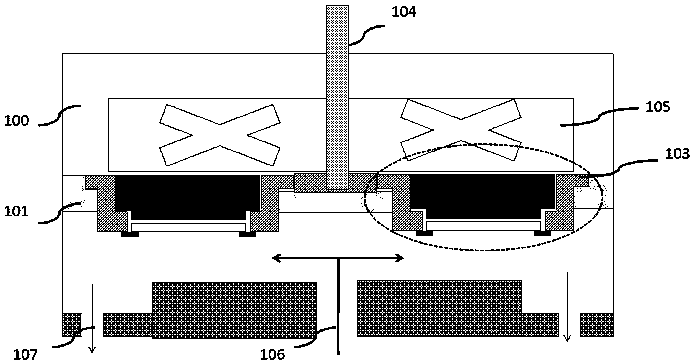

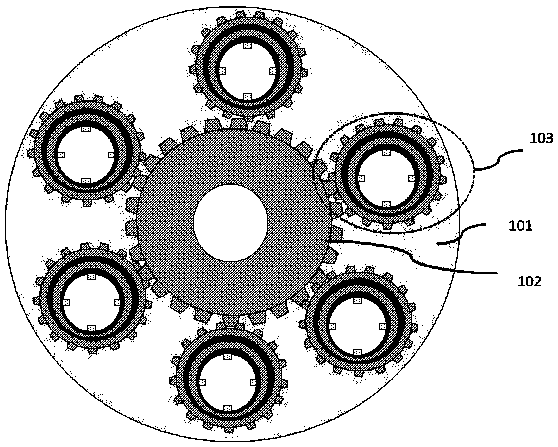

[0071] This embodiment provides a carrier tray for growing thin films on a substrate, which is more suitable for growing thin films under high temperature conditions. The high temperature conditions are usually growth conditions above 600°C, specifically, but not limited to, MOCVD growth devices for growing GaN-based films, AlGaInP-based films, AlGaAs-based films, GaAs-based films . The grown thin film can be used in but not limited to the following types of devices, such as LED light emitting devices or laser devices or solar cell devices.

[0072] The substrate for growing the thin film is preferably a sapphire or germanium-based or gallium arsenide-based or silicon-based or gallium nitride-based substrate or these substrates have additional film layers on their surfaces.

[0073] Specifically, such as Image 6 Shown is a susceptor for growing thin films on a substrate. The carrier plate includes a carrier body 200 and a plurality of individually detachable support blocks...

Embodiment 2

[0086] On the basis of the first embodiment, this embodiment provides an alternative solution, changing the shape of the groove on the inner side wall of the carrier body and the shape of the support block. Figure 11 Provides a schematic longitudinal sectional view from the upper surface side of the carrier tray to the lower surface, the carrier tray body includes several grooves 204 on the inner side wall below the step are T-shaped grooves, including along the horizontal direction A first portion 2041 extending circumferentially from the sidewall surface and a second portion 2042 extending vertically from the first portion 2041 to the lower surface side of the carrier tray, the first portion 2041 of the groove 204 extending circumferentially along the sidewall has a size D1, the second portion 2042 extends circumferentially along the sidewall with a dimension D2. Optionally, the horizontal depth of the first portion 2041 of the groove is consistent with the horizontal depth...

Embodiment 3

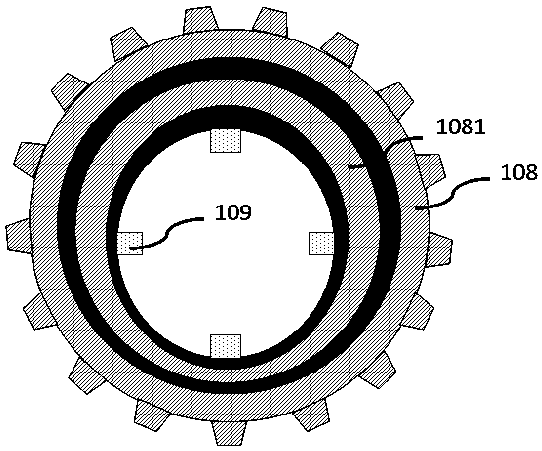

[0094] Different from Embodiment 1 and Embodiment 2, this embodiment provides another design of detachable support blocks. Such as Figure 15 As shown, a susceptor 200 for growing thin films on a substrate, the susceptor includes a susceptor body 200 , the body includes an upper surface side and a lower surface side, and a counterbore penetrates from the upper surface side to the lower surface side. A step 201 is formed on the side wall of the carrier plate in the counterbore, and the terrace of the step 201 is substantially parallel to the upper surface side and the lower surface side.

[0095] The carrier tray 200 includes such as Figure 16 A plurality of individually detachable support blocks 202 are shown, and the plurality of support blocks 202 are in a Z-shaped structure. Such as Figure 17 As shown, a plurality of support blocks 202 include a part suspended and supported by the step 201, and another part extends along the side wall of the body of the carrier to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com